Summary

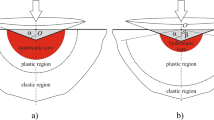

The concept of a yielding region is introduced and its two boundaries are named the inner and the outer yield surfaces. For annealed polycrystalline aluminium, the outer yield surface is defined operationally as the locus of the stress where the stress-strain function becomes parabolic. Experimental data for thin walled tubes of this material, subjected to combined tension-torsion-reverse torsion loading, reveal that small preloading in one direction does not change the shape of the outer yield surface and the subsequent plastic deformation beyond it. When the preloading is large enough, the easy straining phenomenon is observed under reverse loading and reloading in the range of strain through which the specimen has passed.

Zusammenfassung

Der Begriff des Fließbereiches, mit seinen innere und äußere Fließfläche genannten Rändern, wird eingeführt. Für polykristallines Aluminium wird die praktische äußere Fließfläche als geometrischer Ort aller Punkte des Spannungsraumes, in denen die Spannungs-Verzerrungs-Funktion parabolisch wird, definiert. Experimentelle Resultate für dünnwandige Rohre aus diesem Material und unter kombinierter Belastung aus Zug und Torsion mit Richtungsumkehr zeigen, daß eine geringe Vorverformung in einer Richtung die Gestalt der äußeren Fließfläche und die darüber hinausgehende plastische Deformation nicht beeinflußt. Bei großer Vorverformung zeigt sich bei Belastungsumkehr und Wiederbelastung im Bereich der dabei durchlaufenen Verzerrungen die Erscheinung der leichten Verformbarkeit.

Similar content being viewed by others

Abbreviations

- A, A′, A″, etc:

-

stress points or curves in Figs. 1, 2, etc

- B 0 :

-

constant in parabola coefficients

- \(\bar m,\bar k\) :

-

aggregate ratios

- r :

-

deformation mode index

- T, T m :

-

absolute test and melting temperatures

- τ, γ:

-

resolved shear stress and strain

- σ, ɛ:

-

nominal tensile stress and strain

- S, s :

-

nominal shear stress and strain

- S, E :

-

deviatoric stress and strain tensors

- S T,E T :

-

transpose ofS andE

- T, Γ:

-

Magnitudes ofS andE defined by Eq. (3)

- ΔS,ds,dΓ:

-

increments ofS, s, and Γ

- \(\dot \sigma ,\dot S\) :

-

tensile and shear stress rate

- S p ,S r :

-

shear stresses for preloading and reverse loading

- S py ,S ry :

-

outer yield points after preloading and reverse loading

- γ b , ε b ,s b ,Γ b :

-

intercepts on the corresponding strain abscissa

- γ N ,Γ b :

-

corresponding transition strains

- β s :

-

parabola coefficient for single crystals

- βten, βtor, β:

-

parabola coefficients for polycrystals under simple tension, simple torsion and general loadings

- μ(0):

-

shear modulus at zero absolute temperature

References

Prager, W.: A new method of analyzing stress and strains in work hardening plastic solids. J. Appl. Mech.23, 193 (1956).

Hodge, P. G.: Discussion of reference 1. J. Appl. Mech.24, 482 (1957).

Ziegler, H.: A modification of Pragers hardening rule. Q. Appl. Math.17, 55 (1959).

Phillips, A., andJ. L. Tang: The effect of loading path on the yield surface at elevated temperatures. Int. J. Solids and Structures8, 463 (1972).

Mair, W. M., andH. L. D. Pugh: Effects of prestrain on yield surfaces in copper. J. Mech. Eng. Sci.6 (2), 150 (1964).

Williams, J. F., andN. L. Svensson: Effect of tensile prestrain on the yield locus of 1100-F aluminum. J. Strain Anal.5 (2), 128 (1970).

Ivey, H. J.: Plastic stress strain relations and yield surfaces for aluminum alloys. J. Mech. Eng. Sci.3 (1), 15 (1961).

Phillips, A., C. S. Liu, andJ. W. Justusson: An experimental investigation of yield surfaces at elevated temperatures. Acta Mech.14, 119 (1972).

Phillips, A., andR. Kasper: On the foundations of thermoplasticity — an experimental investigation. J. Appl. Mech.40, 891 (1973).

Bell, J. F.: The Experimental Foundations of Solid Mechanics, VIa/1. Berlin-Heidelberg-New York: Springer. 1973.

Gur'ev, A. V., G. V. Malovechko, andYu. D. Khesin: The mechanism of plastic deformation of polycrystalline alloys in the initial micro-yield range. FKhMM (Soviet Materials Sci.)3 (4), 450 (1967).

Taylor, G. I., andH. Quinney: The plastic distorsion of metals. Phil. Trans. Roy. Soc.230, 323 (1931).

Bell, J. F.: The Physics of Large Deformation of Crystalline Solids. Springer Tracts Natur. Phil.14. Berlin-Heidelberg-New York: Springer. 1968.

Mittal, R.: Biaxial loading of aluminum and a generalization of the parabolic law. J. Materials6 (1), 67 (1971).

Moon, H.: An experimental study of incremental response functions in the totally plastic region. Acta Mech. (In press.)

Author information

Authors and Affiliations

Additional information

With 17 Figures

With 17 Figures

Rights and permissions

About this article

Cite this article

Moon, H. An experimental study of the outer yield surface for annealed polycrystalline aluminium. Acta Mechanica 24, 191–208 (1976). https://doi.org/10.1007/BF01190370

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF01190370