Conclusions

-

1.

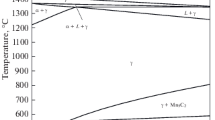

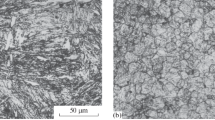

Low-carbon Cr−Ni−Mo−V steels alloyed with aluminum and copper have a good combination of properties after optimal heat treatment. The high stability of supercooled austenite makes it possible to obtain carbon-free martensite after quenching, which undergoes precipitation hardening during aging.

-

2.

The best properties were obtained for steel 0Kh2N5MFYu with 1% Al and for the same steel additionally alloyed with 1.2% Cu. The addition of 0.5% Al induces almost no hardening, and with up to 2% Al the steel is embrittled after aging due to a substantial amount of ferrite. Alloying of this steel with titanium in amounts of 0.24 and 0.55% also leads to embrittlement after aging.

Similar content being viewed by others

Literature cited

P. Hydrean, D. Gullotti, and A. Kitchin Metals Eng. Quart.,8, 4 (1968).

R. Blover, R. Greenwood, and G. Miller, J. Iron Steel Inst., 119–239 (1968).

Kanao Masao Araki Togo, Humata Hideo, and Aoki Takao, J. Iron Steel Inst. Japan,54, 8, 967–977 (1968).

K. A. Lanskaya and Z. G. Kobozeva, "Maraging steels hardened by intermetallic phases NiAl and NiTi," Special Steels and Alloys [in Russian], Collection of Reports No. 7, TsNIIChM (1970).

Additional information

Zhdanov Metallurgical Institute. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 6, pp. 15–17, June, 1973.

Rights and permissions

About this article

Cite this article

Malinov, L.S., Korotich, I.K., Kharlanova, E.Y. et al. Maraging steels with a strength of 110–130 kg/mm2 . Met Sci Heat Treat 15, 461–463 (1973). https://doi.org/10.1007/BF01153261

Issue Date:

DOI: https://doi.org/10.1007/BF01153261