Abstract

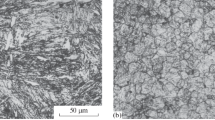

The deformation behavior and the microstructure evolution under the creep of 10Kh9V2MFBR steel (Russian analog of the P92 steel) (in wt %, Fe–8.9% Cr–0.05% Si–0.2% Mn–1.9% W–0.5% Mo–0.25% V–0.07Nb–0.08% N–0.01% B) with the standard (0.1%) and lowered (0.018%) carbon contents have been investigated. After the heat treatment, which included normalizing at 1050°C and tempering at 720–750°C, carbides M 23 C 6 and carbonitrides M(C,N) are formed in the 10Kh9V2MFBR steel, while in the 02Kh9V2MFBR steel (modified P92 steel), carbides M 23 C 6, nitrides M 2N, and carbonitrides M(C,N) as well as δ-ferrite (23%) were found. The measurements of hardness and tensile tests at room and elevated temper-atures did not reveal substantial distinctions in the short-term mechanical properties of both steels. The hardness of steels after tempering was 220 HB. At the same time, the creep characteristics of the steels were found to be different. A decrease in the carbon content leads to an increase in the long-term creep strength and creep limit at 650°C for short-term tests with time-to-fracture shorter than 103 h. The time to fracture of steels with various carbon contents is almost the same in long-term creep tests. Factor responsible for such effect of carbon on the creep strength are discussed.

Similar content being viewed by others

References

Creep-Resistant Steels, Ef. by F. Abe, T.-U. Kern, and R. Viswanathan (Woodhead, Cambridge, 2008).

R. O. Kaybyshev, V. N. Skorobogatykh, and I. A. Shchenkova, “New martensitic steels for thermal power plant: Creep resistance,” Phys. Met. Metallogr. 109, 186–200 (2010).

A. Kostka, K. Tak, R. J. Hellmig, Y. Estrin, and G. Eggeler, “On the contribution of carbides and ultra-fine boundaries to the creep strength of tempered martensitic ferritic steels,” Acta Mater. 55, 539–550 (2007).

N. Dudova, A. Plotnikova, D. Molodov, A. Belyakov, and R. Kaibyshev, “Structural changes of tempered martensitic 9% Cr–2% W–3% Co steel during creep at 650°C,” Mater. Sci. Eng., A 534, 632–639 (2012).

V. Dudko, A. Belyakov, D. Molodov, and R. Kaibyshev, “Microstructure evolution and pinning of boundaries by precipitates in a 9 pct. Cr heat resistant steel during creep,” Metall. Mater. Trans. A 44, 162–172 (2013).

I. Fedorova, A. Belyakov, P. Kozlov, V. Skorobogatykh, I. Shenkova, and R. Kaibyshev, “Laves-phase precipitates in a low-carbon 9% Cr martensitic steel during aging and creep at 923 K,” Mater. Sci. Eng., A 615, 153–163 (2014).

R. Agamennone, W. Blum, C. Gupta, and J. K. Chakravartty, “Evolution of microstructure and deformation resistance in creep of tempered martensitic 9–12% Cr–2% W–5% Co steels,” Acta Mater. 54, 3003–3014 (2006).

G. H. Armaki, R. Chen, K. Maruyama, and M. Igarashi, “Creep behavior and degradation of subgrain structures pinned by nanoscale precipitates in strength-enhanced 5 to 12 Pct Cr ferritic steels,” Metall. Mater. Trans. A 42, 3084–3094 (2011).

F. Abe, “Analysis of creep rates of tempered martensitic 9% Cr steel based on microstructure evolution,” Mater. Sci. Eng., A 510–511, 64–69 (2009).

K. Suzuki, S. Kumai, Y. Toda, H. Kushima, and K. Kimura, “Two-phase separation of primary MX carbonitride during tempering in creep resistant 9Cr1MoVNb steel,” ISIJ Int. 43, 1089–1094 (2003).

A. Yu. Kipelova, A. N. Belyakov, V. N. Skorobogatykh, I. A. Shchenkova, and R. O. Kaibyshev, “Temperinginduced structural changes in steel 10Kh9K3V1M1FBR and their effect on mechanical properties,” Met. Sci. Heat. Treat. 52, 100–110 (2010).

M. Taneike, K. Sawada, and F. Abe, “Effect of carbon concentration on precipitation behavior of M 23 C 6 carbides and MX carbonitrides in martensitic 9Cr steel during heat treatment,” Metall. Mater. Trans. A 35, 1255–1262 (2004).

F. J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, 2nd ed. (Elsevier, Atlanta, GA, 2004)

M. Taneike, F. Abe, and K. Sawada, “Creep-strengthening of steel at high temperatures using nano-sized carbonitride dispersions,” Nature 424, 294–296 (2007).

F. Abe, M. Taneike, and K. Sawada, “Alloy design of creep resistant 9Cr steel using a dispersion of nanosized carbonitrides,” Int. J. Press. Vess. Pip. 84, 3–12 (2007).

I. I. Gorbachev, V. V. Popov, and A. Yu. Pasynkov, “Thermodynamic modeling of carbonitride formation in steels with V and Ti,” Phys. Met. Metallogr. 113, 974–981 (2012).

I. I. Gorbachev, V. V. Popov, and A. Yu. Pasynkov, “Simulation of evolution of precipitates of two carbonitride phases in Nband Ti-containing steels during isothermal annealing,” Phys. Met. Metallogr. 114, 741–751 (2013).

I. Fedorova, A. Kipelova, A. Belyakov, and R. Kaibyshev, “Microstructure evolution in an advanced 9 Pct Cr martensitic steel during creep at 923 K (650°C),” Metall. Mater. Trans. A 44, 128–135 (2013).

F.-S. Yin and W.-S. Jung, “Nanosized MX precipitates in ultra-low-carbon ferritic/martensitic heat-resistant steels,” Metall. Mater. Trans. A 40, 302–309 (2009).

F.-S. Yin, L.-Q. Tian, B. Xue, X.-B. Jiang, and L. Zhou, “Effect of carbon content on microstructure and mechanical properties of 9 to 12 Pct Cr ferritic/martensitic heat-resistant steels,” Metall. Mater. Trans. A 43, 2203–2209 (2012).

L. Helis, Y. Toda, T. Hara, H. Miyazaki, and F. Abe, “Effect of cobalt on the microstructure of tempered martensitic 9Cr steel for ultra-supercritical power plants,” Mater. Sci. Eng., A 510–511, 88–94 (2009).

A. Kipelova, M. Odnobokova, A. Belyakov, and R. Kaibyshev, “Effect of Co on creep behavior of a P911 steel,” Metall. Mater. Trans. A 44, 577–583 (2013).

Sh. Wang, L. Chang, D. Lin, X. Chen, and X. Huih, “High temperature strengthening in 12Cr–W–Mo steels by controlling the formation of delta ferrite,” Metall. Mater. Trans. A 45, 4371–4385 (2014).

W. Yan, P. Hu, L. Deng, W. Wang, W. Sha, Y. Shan, and K. Yang, “Effect of carbon reduction on the toughness of 9CrWVTaN steels,” Metall. Mater. Trans. A 43, 1921–1933 (2012).

S. A. Saltykov, Stereometric Metallography (Metallurgiya, Moscow, 1976) [in Russian].

H. Kitahara, R. Ueji, N. Tsuji, and Y. Minamino, “Crystallographic features of lath martensite in lowcarbon steel,” Acta Mater. 54, 1279–1288 (2006).

D. Richardot, J.-C. Vaillant, A. Arbab, and W. Bendick, The T92/P92 book (Vallourec and Mannesmann Tubes, Boulogne, 2000).

R. O. Kaibyshev, V. N. Skorobogatykh, and I. A. Shchenkova, “Formation of Z-phase and prospects of application of martensitic steels with 11% Cr for operation above 590°C,” Met. Sci. Heat. Treat. 52, 90–99 (2010).

K. Sawada, H. Kushima, M. Tabuchi, and K. Kimura, “Microstructural degradation of Gr.91 steel during creep under low stress,” Mater. Sci. Eng., A 528, 5511–5518 (2011).

K. Kimura, K. Sawada, H. Kushima, and K. Kuba, “Effect of stress on creep deformation of ASME grade P92/T92 steels,” Int. J. Mater. Res. 99, 395–401 (2008).

N. Dudova, A. Belyakov, T. Sakai, and R. Kaibyshev, “Dynamic recrystallization mechanisms operating in a Ni–20% Cr alloy under hot-to-warm working,” Acta Mater. 58, 3624–3632 (2010).

L. Cipolla, H. K. Danielsen, D. Venditti, P. E. Di. Nunzio, J. Hald, and M. A. J. Somers, “Conversion of MX nitrides to Z-phase in a martensitic 12% Cr steel,” Acta Mater. 58, 669–679 (2010).

H. K. Danielsen, P. E. Di. Nunzio, and J. Hald, “Kinetics of Z-phase precipitation in 9 to 12 pct Cr steels,” Metall. Mater. Trans. A 44, 2445–2452 (2013).

A. E. Fedoseeva, P. A. Kozlov, V. A. Dudko, V. N. Skorobogatykh, I. A. Shchenkova, and R. O. Kaibyshev, Microstructural changes in 10Kh9V2MFBR steel at creep during 40000 hours at 600°C,” Phys. Met. Metallogr. (in press).

M. Yoshizawa and M. Igarashi, “Long-term creep deformation characteristics of advanced ferritic steels for USC power plants,” Int. J. Press. Vess. Pip. 84, 37–43 (2007).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.A. Dudko, A.E. Fedoseeva, A.N. Belyakov, R.O. Kaibyshev, 2015, published in Fizika Metallov i Metallovedenie, 2015, Vol. 116, No. 11, pp. 1222–1232.

Rights and permissions

About this article

Cite this article

Dudko, V.A., Fedoseeva, A.E., Belyakov, A.N. et al. Influence of the carbon content on the phase composition and mechanical properties of P92-type steel. Phys. Metals Metallogr. 116, 1165–1174 (2015). https://doi.org/10.1134/S0031918X15110058

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X15110058