Abstract

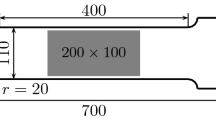

The effect of specimen geometry, specimen size and the specimen orientation on the essential work of fracture for polycarbonate is investigated. Two different test geometries, namely the single-edge notched tension and double-edge notched tension specimens, are used to evaluate the essential work of fracture for crack propagation. It is shown that the specific essential work of fracture for crack propagation,w e′ is independent of the test piece geometries and the size of the test piece. It seems that for a given sheet thickness,w e is a fundamental material property being independent of the specimen geometry and size. The value ofw e does change with the orientation of the initial notch with respect to the melt flow direction. The straight-line relationships between the total specific work of fracture,w f, and ligament length,L, breaks down when the ligament length to specimen thickness ratio is less than about three, because the fracture data fall in the plane stress-plane strain transition region. A plane strain specific essential work of fracture,w le|′, was obtained by extrapolating the best regression line of the data to a zero ligament. For the initial notch in the melt flow direction, values forw e andw le′, were approximately 28 and 3 kJ m−2, respectively. The specific essential work of initiation,w le′ was about 4.3 kJ m−2 ·J R curves (J-Δa curves) were also obtained and it is shown that the intercept and the slope of theJ r curve, i.e.J C and dJ/da, are related tow e and the slope of thew f versus ligament plot.

Similar content being viewed by others

References

N. F. Brown andJ. E. Srawley, ASTM STP 410 (American Society for Testing and Materials, Philadelphia, PA, 1966).

S. Hashemi andJ. G. Williams,J. Mater. Sci. 19 (1984) 3746.

P. L. Fernando andJ. G. Williams,Polym. Engng Sci. 20 (1980) 215.

J. R. Rice,J. Appl. Mech. ASME 35 (1968) 379.

ASTM E813-81, 1981 Annual Book of ASTM Standards, Part 10 (American Society for Testing and Materials, Philadelphia, PA, 1981) pp. 810.

ASTM E813-87, 1987 Annual Book of ASTM Standards, Part 10 (American Society for Testing and Materials, Philadelphia, PA, 1987) pp. 968.

S. Hashemi andJ. G. Williams,Polymer 27 (1986) 384.

Idem, Polym. Engng Sci. 26 (1986) 760.

Idem, Plastics Rubber Process. Applic. 6 (1986) 363.

Idem,J. Mater. Sci. (1992), in press.

D. D. Huang andJ. G. Williams,ibid. 22 (1987) 2503.

R. K. Singh andK. S. Parihar,ibid. 21 (1986) 3921.

K. B. Broberg,Int. J. Fract. 4 (1968) 11.

B. Cotterell andJ. K. Reddel,ibid. 13 (1977) 267.

Y. W. Mai andB. Cotterell,ibid. 32 (1986) 105.

Idem, J. Mater. Sci. 15 (1980) 2296.

Idem, Engng Fract. Mech. 21 (1985) 123.

A. S. Saleemi andJ. A. Nairn,Polym. Engng Sci. 30 (1990) 211.

M. Parvin andJ. G. Williams,Int. J. Fract. 11 (1975) 963.

J. D. Landes andJ. A. Begley, ASTM STP 514 (American Society for Testing and Materials, Philadelphia, PA, 1972) pp. 24–39.

J. M. Hodgkinson andJ. G. Williams,J. Mater. Sci. 16 (1981) 50.

R. J. Ferguson, G. P. Marshall andJ. G. Williams,Polymer 14 (1973) 451.

EGF Recommendations for Determining the Fracture Toughness for Ductile Materials (1987), private communication.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Paton, C.A., Hashemi, S. Plane-stress essential work of ductile fracture for polycarbonate. J Mater Sci 27, 2279–2290 (1992). https://doi.org/10.1007/BF01105033

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF01105033