Abstract

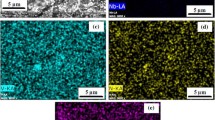

Regions with different microstructures have been identified in the weldments of 9Cr-1 Mo steel. Weldments comprising threthree regions, i.e., weld metal, heat-affected zone (HAZ), and base metal, were oxidized in air at 923 K for different durations up to 500 hr. The crown area of the weld metal was found to form a thicker oxide scale than the other regions of the weldment. When the oxidation kinetics of different regions were compared (by separating out the coupons of the HAZ and the crown and root portions of the weld metal and then oxidizing them), the crown area of the weld was found to oxidize at a much higher rate than the others. Scanning electron microscopy (SEM) was carried out to assess the morphological variations in the different regions of the weldment. The compositional variations in the scales over the different regions have been characterized by the energy-dispersive analyses of X-rays (EDX), and the results thereof have also been corroborated by secondary ion mass spectrometry (SIMS).

Similar content being viewed by others

References

K. Easterling,Introduction of Physical Metallurgy of Welding (Butterworths, 1983).

R. S. Fidler and D. J. Gooch, inProceedings of the BNES Conference on Ferritic Steels for Fast Reactor Steam Generators, S. F. Pugh and E. A. Little, eds. (London, 1978), p. 128.

R. K. Singh Raman and J. B. Gnanamoorthy,Corros. Sci. 34, 1275 (1993).

R. K. Singh Raman and J. B. Gnanamoorthy, Proc. National Welding Seminar, Calcutta, Paper No. 6, 1993.

F. B. Pickering and A. D. Vassiliou,Met. Technol. Oct., 408 (1980).

S. J. Sanderson, inProceedings of the BNES Conference on Ferritic Steels for Fast Reactor Steam Generators, S. F. Pugh and E. A. Little, eds. (London, 1978), p. 120.

R. K. Singh Raman, A. S. Khanna, B. K. Choudhary, and J. B. Gnanamoorthy,Mater. Sci. Eng. A148, 299 (1991).

P. W. Jackson, M. D. Chadwick, and B. L. Graham, inProceedings of the BNES Conference on Ferritic Steels for Fast Reactor Steam Generagors S. F. Pugh and E. A. Little (eds) (London, 1978), p. 488.

R. K. Singh Raman and J. B. Gnanamoorthy,J. Mater. Sci. 27, 3435 (1992).

R. K. Singh Raman, A. S. Khanna, and J. B. Gnanamoorthy, inProceedings of the First International Conference on Microscopy of Oxidation, M. J. Bennet and G. W. Lorimer (eds) (Cambridge, 1990), p. 54.

R. K. Singh Raman, J. B. Gnanamoorthy, and S. K. Roy,Oxid. Met. 40, 1 (1993).

B. J. Cane and R. S. Fidler, inProceedings of the BNES Conference on Ferritic Stells for Fast Reactor Steam Generators, S. F. Pugh and E. A. Little, eds. (London, 1978), p. 193.

D. P. Edmonds and B. Chew, CEGB Report, TPRD/M/1258/N82.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Singh Raman, R.K., Laha, K., Gnanamoorthy, J.B. et al. Oxidation behavior of microstructurally-Different regions in the weldment of 9Cr-1Mo steel. Oxid Met 42, 31–48 (1994). https://doi.org/10.1007/BF01061923

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01061923