Abstract

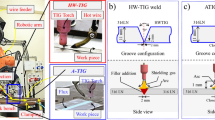

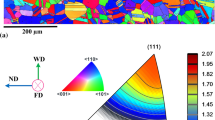

The influence of post-welding heat treatment on the surface and corrosion properties of the interstitial high-entropy alloy (Fe50Mn30Cr10Co10)99C1 has been examined using gas tungsten arc welding (GTAW) and laser welding. The as-welded and post-weld heat-treated samples were characterized using X-ray photoelectron spectroscopy (XPS), X-ray diffraction (XRD), and scanning electron microscopy (SEM). Face-centered cubic (FCC) and hexagonal close-packed (HCP) structures were present in the base metal. There was no change in the phases after welding and post-heat treatment. After laser and GTAW, a small reduction in hardness (25 HV) was noticed. Following both laser and GTAW processes, the base metal's corrosion resistance dropped. However, heat treatment applied after the weld brought the resistance back to almost base metal levels (0.002 mm/year). The development of Mn oxides on the surface, which minimizes the micro-segregation of Cr and generates a uniform Cr oxides layer, is primarily responsible for the increased corrosion resistance in the post-welded samples. This layer also exhibits superior passivation and corrosion resistance. The study clearly demonstrates that, in Mn-containing high-entropy alloys, it is important to suppress elemental Mn content on the surface for improved corrosion resistance.

Similar content being viewed by others

References

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent, Mater. Sci. Eng. A 375–377, 213–218 https://doi.org/10.1016/j.msea.2003.10.257 (2004).

J.W. Yeh, Ann. Chim. Sci. Des Mater. 31, 633–648 https://doi.org/10.3166/acsm.31.633-648 (2006).

X. Chang, M. Zeng, K. Liu, and L. Fu, Adv. Mater. 32, 1–22 https://doi.org/10.1002/adma.201907226 (2020).

P. Agrawal, S. Shukla, S. Gupta, P. Agrawal, and R.S. Mishra, Appl. Mater. Today 21, 100853 https://doi.org/10.1016/j.apmt.2020.100853 (2020).

A. Verma, P. Tarate, A.C. Abhyankar, M.R. Mohape, D.S. Gowtam, V.P. Deshmukh, and T. Shanmugasundaram, Scr. Mater. 161, 28–31 https://doi.org/10.1016/j.scriptamat.2018.10.007 (2019).

B. Cantor, Entropy 16(9), 4749–4768 https://doi.org/10.3390/e16094749 (2014).

J.Y. He, W.H. Liu, H. Wang, Y. Wu, X.J. Liu, T.G. Nieh, and Z.P. Lu, Acta Mater. 62, 105–113 https://doi.org/10.1016/j.actamat.2013.09.037 (2014).

W.H. Liu, Y. Wu, J.Y. He, T.G. Nieh, and Z.P. Lu, Scr. Mater. 68, 526–529 https://doi.org/10.1016/j.scriptamat.2012.12.002 (2013).

Y.H. Zhang, Y. Zhuang, A. Hu, J.J. Kai, and C.T. Liu, Scr. Mater. 130, 96–99 https://doi.org/10.1016/j.scriptamat.2016.11.014 (2017).

A. Gali, and E.P. George, Intermetallics 39, 74–78 https://doi.org/10.1016/j.intermet.2013.03.018 (2013).

A. Sourav, S. Yebaji, and S. Thangaraju, Mater. Sci. Eng. A 793, 139877 https://doi.org/10.1016/j.msea.2020.139877 (2020).

S. Kumar, A. Sourav, B.S. Murty, A. Chelvane, and S. Thangaraju, J. Alloys Compd. 919, 165820 https://doi.org/10.1016/j.jallcom.2022.165820 (2022).

S.F. Liu, Y. Wu, H.T. Wang, J.Y. He, J.B. Liu, C.X. Chen, X.J. Liu, H. Wang, and Z.P. Lu, Intermetallics 93, 269–273 https://doi.org/10.1016/j.intermet.2017.10.004 (2018).

B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, E.P. George, and R.O. Ritchie, Science 345, 1153–1158 https://doi.org/10.1126/science.1254581 (2014).

G.V.S. Kumar, K.R. Mangipudi, G.V.S. Sastry, L.K. Singh, S. Dhanasekaran, and K. Sivaprasad, Sci. Rep. 10, 1–9 https://doi.org/10.1038/s41598-019-57208-x (2020).

Y. Deng, C.C. Tasan, K.G. Pradeep, H. Springer, A. Kostka, and D. Raabe, Acta Mater. 94, 124–133 https://doi.org/10.1016/j.actamat.2015.04.014 (2015).

P. Chauhan, S. Chopra, and S. Thangaraju, Adv. Eng. Mater. 21, 9 https://doi.org/10.1002/adem.201900251 (2019).

C.W. Lu, Y.S. Lu, Z.H. Lai, H.W. Yen, and Y.L. Lee, J. Alloys Compd. 842, 155824 https://doi.org/10.1016/j.jallcom.2020.155824 (2020).

B. Chen, S. Li, H. Zong, X. Ding, J. Sun, and E. Ma, Proc. Natl. Acad. Sci. USA. 117, 16199–161206 https://doi.org/10.1073/pnas.1919136117 (2020).

N.T.C. Nguyen, P. Asghari-Rad, P. Sathiyamoorthi, A. Zargaran, C.S. Lee, and H.S. Kim, Nat. Commun. 11, 1–7 https://doi.org/10.1038/s41467-020-16601-1 (2020).

C. Lee, G. Kim, Y. Chou, B.L. Musicó, M.C. Gao, K. An, G. Song, C. Chou, V. Keppens, W. Chen, and P.K. Liaw, Sci. Adv. 6, 37 https://doi.org/10.1126/sciadv.aaz4748 (2020).

G. Li, M. Liu, S. Lyu, M. Nakatani, R. Zheng, C. Ma, Q. Li, and K. Ameyama, Scr. Mater. 191, 196–201 https://doi.org/10.1016/j.scriptamat.2020.09.036 (2021).

K. Gan, D. Yan, S. Zhu, and Z. Li, Acta Mater. 206, 116633 https://doi.org/10.1016/j.actamat.2021.116633 (2021).

A.J. Zaddach, C. Niu, C.C. Koch, and D.L. Irving, JOM 65, 1780–1789 https://doi.org/10.1007/s11837-013-0771-4 (2013).

F. He, Z. Wang, Q. Wu, D. Chen, T. Yang, J. Li, J. Wang, C.T. Liu, and J.J. Kai, Scr. Mater. 155, 134–138 https://doi.org/10.1016/j.scriptamat.2018.06.002 (2018).

Z. Li, K.G. Pradeep, Y. Deng, D. Raabe, and C.C. Tasan, Nature 534, 227–230 https://doi.org/10.1038/nature17981 (2016).

S. Huang, H. Huang, W. Li, D. Kim, S. Lu, X. Li, E. Holmström, S.K. Kwon, and L. Vitos, Nat. Commun. 9, 1 https://doi.org/10.1038/s41467-018-04780-x (2018).

Z. Li, F. Körmann, B. Grabowski, J. Neugebauer, and D. Raabe, Acta Mater. 136, 262–270 https://doi.org/10.1016/j.actamat.2017.07.023 (2017).

Y.F. Shen, X.X. Dong, X.T. Song, and N. Jia, Sci. Rep. 9, 1–9 https://doi.org/10.1038/s41598-019-44105-6 (2019).

J.H. Zhou, Y.F. Shen, and N. Jia, Int. J. Miner. Metall. Mater. 28, 335–348 https://doi.org/10.1007/s12613-020-2121-1 (2021).

N. Liu, C. Chen, I. Chang, P. Zhou, and X. Wang, Materials (Basel). 11, 1–11 https://doi.org/10.3390/ma11081290 (2018).

Z. Fu, L. Jiang, J.L. Wardini, B.E. MacDonald, H. Wen, W. Xiong, D. Zhang, Y. Zhou, T.J. Rupert, W. Chen, and E.J. Lavernia, Sci. Adv. 4, eaat8712 https://doi.org/10.1126/sciadv.aat8712 (2018).

Z. Wang, I. Baker, Z. Cai, S. Chen, J.D. Poplawsky, and W. Guo, Acta Mater. 120, 228–239 https://doi.org/10.1016/j.actamat.2016.08.072 (2016).

M.V. Klimova, D.G. Shaysultanov, R.S. Chernichenko, V.N. Sanin, N.D. Stepanov, S.V. Zherebtsov, and A.N. Belyakov, Mater. Sci. Eng. A 740–741, 201–210 https://doi.org/10.1016/j.msea.2018.09.113 (2019).

Z. Li, C.C. Tasan, H. Springer, B. Gault, and D. Raabe, Sci. Rep. 7, 40704 https://doi.org/10.1038/srep40704 (2017).

Z. He, N. Jia, H. Yan, Y. Shen, M. Zhu, X. Guan, X. Zhao, S. Jin, G. Sha, Y. Zhu, and C.T. Liu, Int. J. Plast. 139, 102965 https://doi.org/10.1016/j.ijplas.2021.102965 (2021).

M. Traversier, P. Mestre-Rinn, N. Peillon, E. Rigal, X. Boulnat, F. Tancret, J. Dhers, and A. Fraczkiewicz, Mater. Sci. Eng. A 804, 140725 https://doi.org/10.1016/j.msea.2020.140725 (2021).

Y. Lu, A. Mazilkin, T. Boll, N. Stepanov, S. Zherebtzov, G. Salishchev, É. Ódor, T. Ungar, E. Lavernia, H. Hahn, and Y. Ivanisenko, Materialia 16, 101059 https://doi.org/10.1016/j.mtla.2021.101059 (2021).

M. Klimova, D. Shaysultanov, A. Semenyuk, S. Zherebtsov, G. Salishchev, and N. Stepanov, J. Alloys Compd. 849, 156633 https://doi.org/10.1016/j.jallcom.2020.156633 (2020).

L.B. Chen, R. Wei, K. Tang, J. Zhang, F. Jiang, L. He, and J. Sun, Mater. Sci. Eng. A 716, 150–156 https://doi.org/10.1016/j.msea.2018.01.045 (2018).

M. Wang, Z. Li, and D. Raabe, Acta Mater. 147, 236–246 https://doi.org/10.1016/j.actamat.2018.01.036 (2018).

Z. Li, Acta Mater. 164, 400–412 https://doi.org/10.1016/j.actamat.2018.10.050 (2019).

M. Klimova, D. Shaysultanov, A. Semenyuk, S. Zherebtsov, and N. Stepanov, J. Alloys Compd. 851, 156839 https://doi.org/10.1016/j.jallcom.2020.156839 (2021).

M. Song, R. Zhou, J. Gu, Z. Wang, S. Ni, and Y. Liu, Appl. Mater. Today 18, 1–6 https://doi.org/10.1016/j.apmt.2019.100498 (2020).

Z. Wang, and I. Baker, Mater. Sci. Eng. A 693, 101–110 https://doi.org/10.1016/j.msea.2017.03.099 (2017).

Z. He, N. Jia, H. Wang, H. Yan, and Y. Shen, J. Mater. Sci. Technol. 86, 158–170 https://doi.org/10.1016/j.jmst.2020.12.079 (2021).

L. Guo, X. Ou, S. Ni, Y. Liu, and M. Song, Mater. Sci. Eng. A 746, 356–362 https://doi.org/10.1016/j.msea.2019.01.050 (2019).

L. Chen, T. Cao, R. Wei, K. Tang, C. Xin, F. Jiang, and J. Sun, Mater. Sci. Eng. A 772, 138661 https://doi.org/10.1016/j.msea.2019.138661 (2020).

M.Y. He, Y.F. Shen, N. Jia, and P.K. Liaw, Appl. Mater. Today 25, 101162 https://doi.org/10.1016/j.apmt.2021.101162 (2021).

S.A.A. Shams, J.W. Bae, J.N. Kim, H.S. Kim, T. Lee, and C.S. Lee, J. Mater. Sci. Technol. 115, 115–128 https://doi.org/10.1016/j.jmst.2021.10.010 (2022).

J. Li, X. Meng, L. Wan, and Y. Huang, J. Manuf. Process. 68, 293–331 https://doi.org/10.1016/j.jmapro.2021.05.042 (2021).

D. Bandhu, and K. Abhishek, Mater. Manuf. Process 36(12), 1384–1402 https://doi.org/10.1080/10426914.2021.1906897 (2021).

G.P. Yadav, D. Bandhu, B.V. Krishna, N. Gupta, P. Jha, J.J. Vora, S. Mishra, K.K. Saxena, K.H. Salem, and S.S. Abdullaev, J. Adhes. Sci. Technol. 1(22), 0169–4243 https://doi.org/10.1080/01694243.2023.2223367 (2023).

B. Wang, S.J. Hu, L. Sun, and T. Freiheit, J. Manuf. Syst. 56, 373–391 https://doi.org/10.1016/j.jmsy.2020.06.020 (2020).

R. Sokkalingam, K. Sivaprasad, M. Duraiselvam, V. Muthupandi, and K.G. Prashanth, J. Alloys Compd. 817, 153163 https://doi.org/10.1016/j.jallcom.2019.153163 (2020).

R. Sokkalingam, K. Venkatesan, S. Sree-Sabari, S. Malarvizhi, and V. Balasubramanian, Int. J. Res. Eng. Technol. 3, 316–320 https://doi.org/10.15623/ijret.2014.0323069 (2014).

M.A. Derakhshi, J. Kangazian, and M. Shamanian, Vacuum 161, 371–374 https://doi.org/10.1016/j.vacuum.2019.01.005 (2019).

S. Yebaji, A. Saurav, P. Chauhan, B.S. Murty, B. Patil, A. Babu, V. Poddar, and T. Shanmugasundaram, J. Mater. Eng. Perform. 32, 3668–3677 https://doi.org/10.1007/s11665-022-07332-z (2023).

C.M. Lin, and H.L. Tsai, Intermetallics 19, 288–294 https://doi.org/10.1016/j.intermet.2010.10.008 (2011).

R. Sokkalingam, S. Mishra, S.R. Cheethirala, V. Muthupandi, and K. Sivaprasad, Metall. Mater. Trans. A 48, 3630–3634 https://doi.org/10.1007/s11661-017-4140-8 (2017).

H. Luo, Z. Li, A.M. Mingers, and D. Raabe, Corros. Sci. 134, 131–139 https://doi.org/10.1016/j.corsci.2018.02.031 (2018).

Y.L. Chou, Y.C. Wang, J.W. Yeh, and H.C. Shih, Corros. Sci. 52, 3481–3491 https://doi.org/10.1016/j.corsci.2010.06.025 (2010).

A. Rodriguez, J.H. Tylczak, and M. Ziomek-Moroz, ECS Trans. 77, 741 https://doi.org/10.1149/07711.0741ecst (2017).

Q. Ye, K. Feng, Z. Li, F. Lu, R. Li, J. Huang, and Y. Wu, Appl. Surf. Sci. 396, 1420–1426 https://doi.org/10.1016/j.apsusc.2016.11.176 (2017).

K.M. Hsu, S.H. Chen, and C.S. Lin, Corros. Sci. 190, 109694 https://doi.org/10.1016/j.corsci.2021.109694 (2021).

Y. Shi, L. Collins, R. Feng, C. Zhang, N. Balke, P.K. Liaw, and B. Yang, Corros. Sci. 133, 120–131 https://doi.org/10.1016/j.corsci.2018.01.030 (2018).

Y. Zhang, X. Jiang, Y. Fang, Y. Fang, B. Liu, H. Sun, Z. Shao, and T. Song, Mater. Today Commun. 28, 102503 https://doi.org/10.1016/j.mtcomm.2021.102503 (2021).

N. Meena, V. Srivastava, P. Srinivas, M. Gajendra, D.S. Gowtam, A.G. Rao, and N. Prabhu, Trans Indian Inst Met 76(7), 1741–1750 https://doi.org/10.1007/s12666-022-02845-6 (2023).

A. Verma, and S. Thangaraju, Mater. Sci. Tech. 38–14, 1127–1133 https://doi.org/10.1080/02670836.2022.2071398 (2022).

S. Yebaji, L. Chauhan, K. Chakravarthy, A. Verma, H. Natu, S.G. Dommeti, and S. Thangaraju, SSRN Electron. J. https://doi.org/10.2139/SSRN.4241504 (2022).

Z. Li, and D. Raabe, JOM 69, 2099–2106 https://doi.org/10.1007/s11837-017-2540-2 (2017).

H. Nam, C. Park, C. Kim, H. Kim, and N. Kang, Sci. Technol. Weld. Join. 23, 420–427 https://doi.org/10.1080/13621718.2017.1405564 (2018).

A. Verma, H. Natu, I. Balasundar, A. Chelvane, V.L. Niranjani, M. Mohape, G. Mahanta, S. Gowtam, and T. Shanmugasundaram, Sci. Technol. Weld. Join. 27–3, 197–203 https://doi.org/10.1080/13621718.2022.2029116 (2022).

H. Murakawa, Handb. Laser Weld. Technol. 2, 374–398 https://doi.org/10.1533/9780857098771.2.374 (2013).

A. Lodh, K. Thool, and I. Samajdar, Trans. Indian Inst. Met. 75, 983–995 https://doi.org/10.1007/s12666-022-02540-6 (2022).

B. Kim, S. Kim, and H. Kim, Adv. Mater. Sci. Eng. 2018, 7638274 https://doi.org/10.1155/2018/7638274 (2018).

Y.-S. Lu, C.-W. Lu, Y.-T. Lin, H.-W. Yen, and Y.-L. Lee, J. Electrochem. Soc. 167, 081506 https://doi.org/10.1149/1945-7111/ab8de4 (2020).

J. Oliveira, T. Curado, Z. Zeng, J. Lopes, E. Rossinyol, J.M. Park, N. Schell, F. Braz Fernandes, and H.S. Kim, Mater. Des. 189, 108505 https://doi.org/10.1016/j.matdes.2020.108505 (2020).

U. Martin, J. Ress, J. Bosch, and D.M. Bastidas, Appl. Sci. 10, 1–11 https://doi.org/10.3390/app10249104 (2020).

S. Fajardo, I. Llorente, J. Jiménez, N. Calderón, D. Herrán-Medina, J. Bastidas, J. Ress, and D. Bastidas, Appl. Surf. Sci. 513, 145852 https://doi.org/10.1016/j.apsusc.2020.145852 (2020).

D.M. Bastidas, J. Ress, J. Bosch, and U. Martin, Metals. 11, 1–45 https://doi.org/10.3390/met11020287 (2021).

Acknowledgments

We are very thankful to Dr. C. P. Ramanarayanan, Vice-Chancellor, DIAT (DU) for their constant support. This work is supported by the Naval Research Board, Defence Research and Development Organizations for funding the work through project No. NRB/4003/PG/MAT/501.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yebaji, S., Sudeep Kumar, T., Verma, A. et al. Effect of Post-Welding Treatment on Corrosion Behavior of Laser and Gas Tungsten Arc-Welded (Fe50Mn30Co10Cr10)99C1 Interstitial High-Entropy Alloy. JOM 75, 5568–5580 (2023). https://doi.org/10.1007/s11837-023-06210-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-06210-w