Abstract

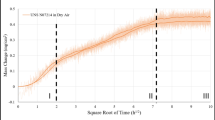

The oxidation resistance of Al-deposited Fe−Cr−Al foils containing small amounts of La and Ce was assessed by a cyclic oxidation test with temperature varying between room temperature and 1323 K to 1423 K in static air. (1) The Al content of Fe−Cr−Al−La, Ce foils can be increased by depositing an Al layer from the vapor phase. The deposition of a 1-μm-thick Al layer on both sides of the 50-μm-thick foil is equivalent to a 1.5 mass% increase in the Al content. The deposited Al diffuses into the foil during heat treatment. The uniform distribution of Al is obtained by heating at 1273 K for 18 ks. (2) After the initial transition stage the oxidation follows the parabolic law until breakaway sets in. The scale consists mainly of α-Al2O3 during the parabolic period. (3) The increase in the Al content by more than 5 mass% by the Al-deposition remarkably improves high-temperature oxidation resistance (smaller parabolic rate constant and longer protection time). (4) The Al-deposited foils have better oxidation resistance than the conventional foils with the same contents of Al and rare-earth elements. This is attributable to the different nature of the initially formed oxide on the Al-deposited foil. (5) The so-called rare-earth element effect was also observed for the Al-deposited foils. Predominant diffusion of oxygen through the Al2O3 scale and vacancy-sink mechanism are applicable to the present results.

Similar content being viewed by others

References

M. Nonnenmann,SAE paper 850131 (1985).

P. N. Hawker, C. Jaffray, and A. J. J. Wilkins,SAE paper 880317 (1988).

S. Pelters, F. W. Kaiser, and W. Maus,SAE paper 890488 (1989).

T. Takeda and T. Tanaka,SAE paper 910615 (1991).

S. Isobe,Denki-seikoh 58, 104 (1987).

K. Ohmura, M. Fukaya, M. Yamanaka, H. Abo, and F. Fudanoki,Proc. Int. Conf. on Stainless Steels, 1991, p. 1212.

A. Andoh, Y. Uchida, and Y. Hirose,CAMP-ISIJ 2, 721 (1989).

A. Andoh, M. Saito, Y. Uchida, and T. Kittaka,CAMP-ISIJ 4, 1776 (1991).

K. Masaki, H. Miyake, M. Soda, T. Kittaka, and T. Yoshii,Nisshin Steel Technical Report, No. 65, 61 (1992).

H. Okabe,J. Jpn. Inst. Met. 49, 891 (1985).

T. Amano, S. Yajima, and Y. Saito,J. Jpn. Inst. Met. 41, 1074 (1977).

J. K. Tien and F. S. Pettit,Met. Trans. 3, 1587 (1972).

C. A. Barrett,Oxid. Met. 30, 361 (1988).

S. Ueda, H. Tominaga, and S. Mitsuda,J. Met. Fin. Soc. Jpn. 24, 681 (1973).

F. A. Golightly, F. H. Stott, and G. C. Wood,J. Electrochem. Soc. 126, 1035 (1979).

T. A. Ramanarayanan, R. Ayer, R. Petkovic-Luton, and D. P. Leta,Oxid. Met. 29, 445 (1988).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Andoh, A., Taniguchi, S. & Shibata, T. High-temperature oxidation of Al-deposited stainless-steel foils. Oxid Met 46, 481–502 (1996). https://doi.org/10.1007/BF01048642

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF01048642