Abstract

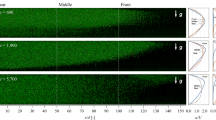

Local mass transfer rates at the wall of a pipe downstream of constricting nozzles have been measured using the electrochemical limiting diffusion current technique for different electrolyte Schmidt numbers. The familiar peaked axial distribution of mass transfer downstream of the nozzle was verified and the peak mass transfer values were found to agree well with the data of Tagget al. [1]. An overall correlation of the data in terms of both Reynolds number and nozzle expansion ratio produced the equation

Limiting current-time traces produced evidence of the highly turbulent flow in the recirculation zone near the position of peak mass transfer.

Similar content being viewed by others

Abbreviations

- A :

-

electrode surface area

- D :

-

diameter

- D :

-

diffusion coefficient

- C :

-

bulk concentration of Fe(CN) 3-6

- F :

-

Faraday number

- I L :

-

limiting current

- k :

-

mass transfer coefficient

- u :

-

liquid velocity

- x :

-

distance downstream of nozzle

- μ:

-

dynamic viscosity

- ϱ:

-

density

- Re :

-

Reynolds number,Duϱ/μ

- Sc :

-

Schmidt number,μ/ϱD

- Sh :

-

Sherwood number,kD/D

- 1:

-

nozzle

- 2:

-

downstream pipe

- FD:

-

fully developed

- P:

-

peak (maximum) value

References

D. J. Tagg, M. A. Patrick and A. A. Wragg,Trans. Instn. Chem. Engrs 57 (1979) 176.

K. M. Krall and E. M. Sparrow,J. Heat Transfer 88 (1966) 131.

S. M. Chouikhi, PhD Thesis, University of Exeter (1985).

S. M. Chouikhi, M. A. Patrick and A. A. Wragg, Proc. Int. Conf. Physical Modelling of Multiphase Flow, Coventry, UK, (April 1983), p. 53ff.

Idem, S. M. Chouikhi, M. A. Patrick and A. A. Wragg., Proc. 3rd Int. Conf. Multi-phase Flow, The Hague, Netherlands, May 1987.

A. K. Runchal,Int. J. Heat Mass Transfer 14 (1971) 781.

T. Sydberger and U. Lotz,J. Electrochem. Soc. 129 (1982) 276.

J. B. Harris, PhD Thesis, University of Exeter (1987).

S. J. Wilkin and H. W. K. Cheung, Central Electricity Research Laboratories, Leatherland, UK, Report No. TPRD/L/E 500051/M82 (1982).

B. Poulson and R. Robinson,Corros. Sci. 26 (1986) 265.

A. A. Wragg, D. J. Tagg and M. A. Patrick,J. Appl. Electrochem. 10 (1980) 43.

M. O. Awe, G. P. Hammond and J. Ward, Proc. 7th Int. Heat Transfer Conf., Munich (Sept. 1982) p. 15.

B. Poulson,Corros. Sci. 23 (1983) 391.

J. G. A. Pembery, PhD Thesis, University of Exeter (1985).

A. A. Wragg,Chem. Engr. 316 (1977) 39.

J. R. Selman and C. W. Tobias,Adv. Chem. Eng. 10 (1978) 211.

F. P. Berger and K-F. F-L. Hau,Int. J. Heat Mass Transfer 20 (1977) 1185.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chouikhi, S.M., Patrick, M.A. & Wragg, A.A. Mass transfer downstream of nozzles in turbulent pipe flow with varying Schmidt number. J Appl Electrochem 17, 1118–1128 (1987). https://doi.org/10.1007/BF01023595

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF01023595