Abstract

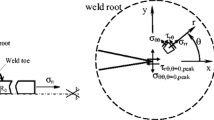

A method for calculating stress intensity factors for edge and surface cracks in weldments has been presented. The weight function method was applied and appropriate weight functions have been derived using the Petroski-Achenbach crack opening displacement expression. The derived weight functions account for both the global weldment geometry and the weld profile characterised by the weld angle.

Finally analysis of several parameters such as the type of loading, crack aspect ratio, weld angle and weld toe radius have been carried out assessing their effect on the stress intensity factor.

The calculated stress intensity factors were verified against available finite element data.

Very close agreement was achieved between the finite element data and the weight function based calculations.

Résumé

On présente une méthode de calcul des facteurs d'intensité de contraintes dans le cas de fissures de bord et de surface dans des soudures. On applique la méthode des fonctions pondérales et, en utilisant l'expression du COD proposée par Petroski et Achenbach, on tire les fonctions pondérales appropriées, qui tiennent compte de la géométrie générale de la soudure et du profil du joint, caractérisé par l'angle à la racine. Enfin, on a procédé à l'analyse de divers paramètres tels que le type de sollicitation, l'aspect de la fissure, l'angle et le rayon du congé à la racine, en vue de déterminer leur effet sur le facteur d'intensité des contraintes.

On vérifie les facteurs d'intensité de contraintes par rapport aux données par éléments finis qui sont disponibles. On obtient un accord très proche entre les données numériques venant des éléments finis et les calculs basés sur les fonctions pondérales.

Similar content being viewed by others

Abbreviations

- a :

-

crack length for an edge crack or depth for a semi-elliptical surface crack

- c :

-

half crack length for semi-elliptical surface crack

- E :

-

modulus of elasticity

- F, F(a/t) :

-

geometric stress intensity correction factor

- F, F,(a/t) :

-

geometric correction factor for the reference stress intensity factor

- F x sf :

-

geometric stress intensity factor for an edge crack emanating from an angular corner α in a semi-finite plate with a step

- F 90 sf :

-

geometric stress intensity correction factor for a crack emanating from the right angle corner (α = 90°) in a semi-finite plate with a step

- G(a/t) :

-

parameter of the crack opening displacement function

- H :

-

generalised modulus of elasticityH = E — for plane stressH = E/(1 —v 2) — for plane strain

- h :

-

weld leg length (or the step thickness)

- I 1 (a), I 2 (a), I 3 (a) :

-

parameters of the crack opening displacement function

- K :

-

stress intensity factor

- K r :

-

reference stress intensity factor corresponding to the local reference stressσ r(x) and nominal stressS r

- K p e :

-

stress intensity factor for an edge crack in a flat plate

- K w e :

-

stress intensity factor for an edge crack in a weldment

- K p s :

-

stress intensity factor for a semi-elliptical surface crack in a flat plate

- K w s :

-

stress intensity factor for a semi-elliptical surface crack in a weldment

- m(x, a) :

-

weight function

- m(x, a, a) :

-

weight function for an edge crack emanating from an angular corner α in a finite thickness plate with a step or weight function for an edge crack in a T-butt welded joint

- m B (x, a) :

-

Bueckner's weight function for an edge crack in a flat plate

- m s (x, a, c) :

-

weight function for a semi-elliptical surface crack in a flat plate

- √Q= π/2 :

-

elliptical integral of second kind for a circular crack

References

H. Jakubczak and G. Glinka,International Journal of Fatigue 8, No. 2 (1986) 51–57.

H.F. Bueckner,ZAMM 50, No. 9 (1970) 529–546.

J.R. Rice,International Journal of Solids and Structures 8, No. 5 (1972) 751–758.

M. Oore and D.Y. Burns,Journal of Pressure Vessel Technology, ASME 102, No. 2 (1980) 202–211.

L. Grueter, W. Huget, and H. Kylla,Zeitschrift fur Werkstofftechnik, Nos. 1 and 2 (1984) 10–17 and 46–49.

X. Niu and G. Glinka,International Journal of Fracture 35, No. 1 (1987) 3–20.

H.J. Petroski and J.D. Achenbach,Engineering Fracture Mechanics 10, No. 2 (1978) 257–266.

C. Mattheck, D. Munz, and H. Stamm,Engineering Fracture Mechanics 18, No. 3 (1983) 633–641.

C. Mattheck, P. Morawietz, and D. Munz,International Journal of Fracture 23, No. 2 (1983) 201–212.

H.F. Bueckner,ZAMM 51 (1971) 97–109.

J.C. Newman and I.S. Raju,Engineering Fracture Mechanics 15, No. 2 (1981) 185–192.

X. Niu and G. Glinka, “Theoretical and Experimental Analyses of Surface Fatigue Cracks in Weldments”, ASTM STP, Symposium on Surface Crack Growth, Reno, Nevada, 25 April 1988 (to be published).

R. Bell, “Determination of Stress Intensity Factors for Weld Toe Defects” Final Report, BSS 22ST. 23440-2-1083/1, Faculty of Engineering, Carleton University, Ottawa, Canada, October 1985.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Niu, X., Glinka, G. Stress-intensity factors for semi-elliptical surface cracks in welded joints. Int J Fract 40, 255–270 (1989). https://doi.org/10.1007/BF00963660

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00963660