Conclusions

-

1.

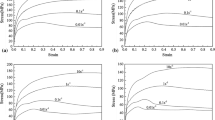

After heat treatment of 37KhN3 and 40Kh1NVA steel specimens, a stable tensile strength of 245–255 kg/ mm2, with a reduction in area of 25 to 30% is obtained.

-

2.

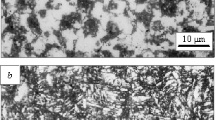

The good mechanical properties of heat-treated specimens are also accounted for by high dispersion and some orientation of structural elements.

-

3.

A heat treatment at which deformation occurs above c3 is better since it ensures an optimal combination of strength and plasticity.

-

4.

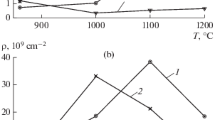

The use of a magnetic field during the transformation of austenite to martensite produces homogenous mechanical properties and slightly improves strength characteristics.

Similar content being viewed by others

References

V. V. Parfenov and G. I. Yanus, Zhur. Tekh. Fiz., Vol. XVIII, No. 2, 1948.

B. A. Sadikov, Zavodskaya laboratoriya, No. 4, 1937.

Rights and permissions

About this article

Cite this article

Astaf'yeva, Y.V., Bernshteyn, M.L., Kidin, I.N. et al. All-union scientific and technological conference on technology and automation of the heat treatmentof metals. Met Sci Heat Treat 3, 372–375 (1961). https://doi.org/10.1007/BF00810412

Issue Date:

DOI: https://doi.org/10.1007/BF00810412