Abstract

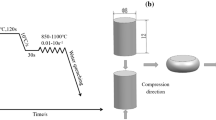

Hot deformation behavior of a high-strength steel Docol 1500 Bor was investigated by compression tests on a thermal–mechanical simulator Gleeble 3500. The workability of tested steel was analyzed by building processing maps at three strains based on the test results of flow stresses. The essential deformation mechanism was further studied based on the deformation texture analysis on a scanning electronic microscope with a TSL-OIM™EBSD system. It was found that that strain can affect the workability of the tested steel remarkably. At the engineering strain of 0.6, obvious textures in martensite mainly include recrystallization textures <110>//ND and other texture components <110>//RD and {001} <100>, etc. Dynamic recrystallization and recrystallization texture component <111>//ND in deformed austenite can contribute to increasing the workability of a steel Docol 1500 Bor. Finally, the optimized deformation conditions of the tested steel were obtained.

Similar content being viewed by others

References

Y.G. Deng, H.S. Di, M.Y. Hu, J.C. Zhang, and R.D.K. Misra, High Strength-High Ductility Combination Ultrafine-Grained Dual-Phase Steels Through Introduction of High Degree of Strain at Room Temperature Followed by Ultra rapid Heating During Continuous Annealing of a Nb-Microalloyed Steel, J. Mater. Eng. Perform., 2017, 26, p 3007–3015

W. Wang, Y. Ma, M.X. Yang, P. Jiang, F.P. Yuan, and X.L. Wu, Strain Rate Effect on Tensile Behavior for a High Specific Strength Steel: From Quasi-Static to Intermediate Strain Rates, Metals, 2018, 8, p 11

P. Zhou, Z.Y. Liang, and M.X. Huang, Microstructural Evolution of a Nanotwinned Steel Under Extremely High-Strain-Rate Deformation, Acta Mater., 2018, 149, p 407–415

R.X. Chai, C. Guo, and L. Yu, Two Flowing Stress Models for Hot Deformation of XC45 Steel at High Temperature, Mater. Sci. Eng., A, 2012, 534, p 101–110

F. Chen, H. Wang, H.J. Zhu, H.Y. Zhu, F.C. Ren, and Z.S. Cui, High-Temperature Deformation Mechanisms and Physical-Based Constitutive Modeling of Ultra-Supercritical Rotor Steel, J. Manuf. Process., 2019, 38, p 223–234

L. Chen, W.Y. Sun, J. Lin, G.Q. Zhao, and G.C. Wang, Modelling of Constitutive Relationship, Dynamic Recrystallization and Grain Size of 40Cr Steel During Hot Deformation Process, Results Phys., 2019, 12, p 784–792

A.A. Lakshmi, C. Rao, J. Gangadhar, C. Srinivasu, and S.K. Singh, Review of Processing Maps and Development of Qualitative Processing Maps, Mater. Today Proc., 2017, 4, p 946–956

P. Gong, E.J. Palmiere, and W.M. Rainforth, Thermomechanical Processing Route to Achieve Ultrafine Grains in Low Carbon Micro Alloyed Steels, Acta Mater., 2016, 119, p 43–54

H. Rastegari, A. Kermanpur, A. Najafizadeh, D. Porter, and M. Somani, Warm Deformation Processing Maps for the Plain Eutectoid Steels, J. Alloy. Compd., 2015, 626, p 136–144

B. Kishor, G.P. Chaudhari, and S.K. Nath, Hot Deformation Characteristics of 13Cr-4 Ni Stainless Steel Using Constitutive Equation and Processing Map, J. Mater. Eng. Perform., 2016, 25, p 2651–2660

Y. Han, D.N. Zou, Z. Chen, G.W. Fan, and W. Zhang, Investigation on Hot Deformation Behavior of 00Cr23Ni4N Duplex Stainless Steel Under Medium-High Strain Rates, Mater. Charact., 2011, 62, p 198–203

Y.Q. Ning, Z.K. Yao, Y.Y. Lei, H.Z. Guo, and M.W. Fu, Hot Deformation Behavior of the Post-cogging FGH4096 Superalloy with Fine Equiaxed Microstructure, Mater. Charact., 2011, 62, p 887–893

T.D. Kil, J.M. Lee, and Y.H. Moon, Quantitative Formability Estimation of Ring Rolling Process by Using Deformation Processing Map, J. Mater. Process. Technol., 2015, 220, p 224–230

K.K. Saxena, V. Pancholi, S.K. Jha, G.P. Chaudhari, D. Srivastava, and G.K. Dey, A Novel Approach to Understand the Deformation Behavior in Two Phase Region Using Processing Map, J. Alloy. Compd., 2017, 706, p 511–519

C.R. Anoop, A. Prakash, S.K. Giri, S.V.S.N. Murty, and I. Samajdar, Optimization of Hot Workability and Microstructure Control in a 12Cr-10Ni Precipitation Hardenable Stainless Steel: An Approach Using Processing Maps, Mater. Charact., 2018, 141, p 97–107

W. Xu, P.E.J. Rivera-Díaz-del-Castillo, W. Wang, K. Yang, V. Bliznuk, L.A.I. Kestens, and S.V.D. Zwaag, Genetic Design and Characterization of Novel Ultrahigh Strength Stainless Steels Strengthened by Ni3Ti Intermetallic Nanoprecipitates, Acta Mater., 2010, 58, p 3582–3593

N. Tsuji, Y. Matsubara, and Y. Saito, Dynamic Recrystallization of Ferrite in Interstitial Free Steel, Scr. Mater., 1997, 37, p 477–484

S.V.S. Narayana Murty and B. Nageswara Rao, On the Development of Instability Criteria During Hot Working with Reference to IN 718, Mater. Sci. Eng., A, 1998, 254, p 76–82

H. Hu, Texture of Metals, Texture, 1974, 1, p 233–258

Acknowledgments

This work was funded by Major Scientific and Technological Specialties of High-grade CNC Machine Tools and Basic Manufacturing Equipment Grant No. 2018ZX04023002, National Natural Science Foundation of China under Grant No. 51205342, Natural Science Foundation of Hebei Province of China under Grant Nos. E2016203217 and E2016203119.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, ZQ., Liu, LG., Wang, G. et al. Workability of High-Strength Automobile Steel at High Temperatures Using Hot Processing Maps and Electron Backscatter Diffraction. J. of Materi Eng and Perform 28, 6157–6164 (2019). https://doi.org/10.1007/s11665-019-04345-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04345-z