Conclusions

-

1.

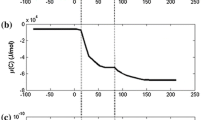

Carbon diffusion coefficients were determined for G13M powder metallurgy steel produced under various conditions.

-

2.

It was established that structural defects have an inhibiting effect on carbon diffusion in this steel.

-

3.

The optimum conditions of preparation of G13M steel (t = 1200°C and τ =20 min) ensure a sufficiently uniform distribution of manganese in the austenite.

Similar content being viewed by others

Literature cited

Yu. G. Dorofeev, N. T. Zherditskii, and V. A. Kolesnikov, Poroshkovaya Met., No. 11 (1970).

S. D. Gertsriken and I. Ya. Dekhtyar, Solid Phase Diffusion in Metals and Alloys [in Russian], Fizmatgiz, Moscow (1960).

P. L. Gruzin, Ya. A. Polikarpov, and M. A. Shumilov, Zavod. Lab., No. 14 (1955).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 11 (119), pp. 29–32, November, 1972.

A 13% Mn steel produced by powder metallurgy; G13L, also referred to in this article, is a standard cast steel of the same composition-Translator.

Rights and permissions

About this article

Cite this article

Dorofeev, Y.G., Mural', V.V., Zherditskii, N.T. et al. Carbon and manganese diffusion processes in G13M sintered steel. Powder Metall Met Ceram 11, 885–887 (1972). https://doi.org/10.1007/BF00806647

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00806647