Conclusions

-

1.

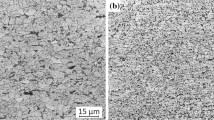

The plasma heating process of 9KhF steel provides obtaining of hardened surface cases with a martensitic structure. The depth of the hardened cases with a microhardness of more than 800 H may reach 1 mm.

-

2.

The depth of the hardened case changes proportionally to the parameter P/(dnP)0.4, where P is the arc power, dn is the diameter of the plasmatron delivery nozzle, and v is the rate of movement of the plasmatron.

-

3.

The thermal efficiency of the plasma-hardening process of 9KhF steel is 25–30% with the use of argon as the plasma-forming gas. With operation of the gun with a mixture of Ar+70% N2 the thermal efficiency decreases to 9–10%.

Similar content being viewed by others

Literature cited

V. S. Kraposhin, "Heat treatment of steel and alloys with use of a laser beam and other progressive forms of heating," in: The Results of Science and Technology, "Metallurgy and Heat Treatment" Series, Vol. 21 [in Russian], Vsesoyuz. Inst. Nauch. i Tekh. Inf., Moscow (1987), pp. 144–206.

F. H. Reinke, "Aufbau ledeburitischer randschichten durch umschmelzbehandlung von nocken und nockenfolgern," in: 31 Int. wiss. Kollog., Ilmenau, No. 2, V. A4, A5, A6 (1986), pp. 163–170.

"Hardening of the surface of a cast iron camshift," Jpn. Patent Application 61-207, 517, IPC S 21 D 9/30.

V. A. Linnik, A. K. Onegina, A. I. Andreev, et al., "Surface hardening of steels by the plasma-hardening methods," Metalloved. Term. Obrab. Met., No. 3, 2–5 (1983).

G. A. Iskhakova and Kh. M. Rakhimyanov, "An investigation of the microstructure and mechanical properties of 45 steel after plasma heat treatment," Élektron. Obrab. Mater., No. 5, 24–27 (1987).

S. S. Kravchenko, "The influence of the method parameters of plasma machining on the temperature distribution in the cutting zone," Fiz. Khim. Obrab. Mater., No. 4, 30–34 (1982).

I. Ch. Kopechkaya, "The structure and phase composition of the surface layers of steels and refractory metals after the action of concentrated energy flows," Candidate's Thesis, Technical Sciences, Moscow (1989).

S. I. Gubenko, "Phase transformations in nonmetallic inclusion in laser heat treatment of steel," Izv. VUZ. Chern. Met., No. 12, 67–71 (1986).

V. S. Kraposhin, "The relationship of the depth of hardening of steels and alloys to the conditions of laser irradiation," Fiz. Khim. Obrab. Mater., No. 6, 88–96 (1988).

E. Ohmura and Y. Namba, "Microstructure of hypoeutectoid steel in laser hardening process," Trans. Jpn. Soc. Mech. Eng.,A51, No. 469, 2231–2237 (1985).

Additional information

Institute of Problems of the Technology of Microelectronics and Special Purity Materials, Academy of Sciences of the USSR. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 11, pp. 13–17, November, 1989.

Rights and permissions

About this article

Cite this article

Kraposhin, V.S., Bobrov, A.V. & Gaponenko, O.S. Surface hardening of 9KhF steel by heating with a plasma gun. Met Sci Heat Treat 31, 816–821 (1989). https://doi.org/10.1007/BF00795563

Issue Date:

DOI: https://doi.org/10.1007/BF00795563