Conclusions

The insufficiently high degree of perfection of interparticle contacts at high homologous sintering temperatures of titanium nickelide is related to specifics of its superelastic behavior and is explained by rupture of the contact bonds formed in pressing during preparation of the material.

In the 30–50% porosity range, which is most important for providing a high level of reversible deformation, the quality of interparticle contacts has the prevailing influence on porosity.

The unsteady (with a maximum) character of the relationship of deformation until fracture to porosity is related both to nonuniformity of deformation of porous titanium nickelide and to specifics of deformation according to the martensite transformation mechanism.

Similar content being viewed by others

Literature cited

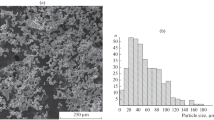

S. M. Solonin, I. F. Martynova, V. V. Skorokhod, et al., “The influence of particle size and morphology on the behavior of titanium nickelide powder in pressing,” Poroshk. Metall., No. 7, 37–41 (1988).

S. M. Solonin, I. F. Martynova, V. V. Skorokhod, et al., “An investigation of superelastic behavior in cyclic deformation of powder metallurgy titanium nickelide,” ibid., No. 8, pp. 26–30 (1988).

V. V. Skorokhod, S. M. Solonin, I. F. Martynova, et al., “Sintering of titanium nickelide powder,” ibid., No. 4, 17–21 (1990).

S. M. Solonin, I. F. Martynova, V. V. Skorokhod, et al., “The influence of ‘inert’ additions on the superelastic behavior of powder metallurgy titanium nickelide,” ibid., No. 9, 14–19 (1986).

V. V. Skorokhod and S. M. Solonin, Physical Metallurgical Fundamentals of Sintering of Powders, Metallurgiya, Moscow (1984).

I. I. Kornilov, O. K. Belousov, and E. V. Kachur, Titanium Nickelide and Other Alloys with a “Memory” Effect [in Russian], Nauka, Moscow (1977).

A. Ya. Krasovskii, “Certain rules of deformation and fracture of iron-base porous cermet materials (Report 2),” Poroshk. Metall., No. 5, 9–15 (1964).

A. A. Shaposhnikov, Mechanical Tests of Metals [in Russian], Mashgiz, Moscow (1954).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 3(339), pp. 34–38, March, 1991.

Rights and permissions

About this article

Cite this article

Skorokhod, V.V., Solonin, S.M., Martynova, I.F. et al. Physicomechanical properties of porous titanium nickelide. Powder Metall Met Ceram 30, 196–199 (1991). https://doi.org/10.1007/BF00794905

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00794905