Conclusions

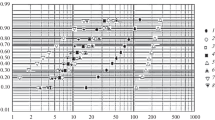

The nature of the liquid-metal film flow about the end of the pulverized billet is defined by its rotational velocity. In the case of a turbulent film flow regime gas is captured and pores are formed in individual powder particles.

The greatest number of porous particles produced in a single pulverization regime is found in a large-fraction powder while the smallest quantity is found in the finely dispersed powder with grain sizes less than 100μn.

Increasing the helium content in the pulverization medium to 100% produces a discontinuous increase in the number of porous particles as a result of the reduced viscosity of the gaseous medium and the high penetration power of the helium. The smallest number of porous particles is formed when pulverization takes place in a medium with a volumetric argon content in excess of 30%.

The pore size in the powder particles is virtually independent of the production regime and usually amounts to about 25–35 % of the particle diameter. The average gas-pore volume is 2–3% of the volume of the powder particle.

To achieve minimum microporosity in compacted billets fabricated by the methods of powder metallurgy, it is expedient to use 100μm powder fractions, produced at a billet rotation velocity of 35–40 m/sec.

Similar content being viewed by others

Literature cited

Yu. F. Ternovoi, A. G. Tsipunov, S. B. Kuratchenko, et al., “Pore formation in a pulverized powder,”Porosh. Metall., No. 1, 10–15 (1985).

S. Brettschneider,The Properties of Gases and Liquids [Russian translation], Khimiya, Moscow-Leningrad (1966).

V. T. Musienko, “Certain quantitative relationships governing the formation of granules in centrifugal pulverization of a rotating billet,”Porosh. Metall., No. 8, 1–7 (1979).

G. Batchelor,Introduction to the Dynamics of Fluids [Russian translation], Mir, Moscow (1973).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 12(348), pp. 1–7, December, 1991.

Rights and permissions

About this article

Cite this article

Koshelev, V.Y., Musienko, V.T. Microporosity of powders produced by centrifugal sputtering. Powder Metall Met Ceram 30, 989–993 (1991). https://doi.org/10.1007/BF00794425

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00794425