Abstract

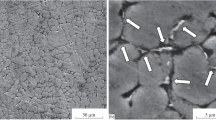

In the present paper, results of a study of the impact of high-energy effects on the surface morphology and on the formation of the internal structure in PMS-1 copper particles are reported. It is shown that the mechanical milling of the copper powder in a planetary mill leads to the formation of powder agglomerates with a layered structure consisting of numerous deformed ultrafine particles. It is found that the volume of the agglomerated particles involves the defects in the form of microcracks and closed micropores with some content of the initial gas. Subsequent treatment of the powder in an argon-helium plasma jet leads to the formation of dense particles as well as particles with distributed gas volumes or a single cavity. It was found that, as the molten metal interacted with localized gas volumes during the plasma treatment, local oxidation of the material occurred. A dispersion-strengthened structure with copper oxide compounds of a predominantly round shape, ranging in size from tens of nanometers to 7 µm and uniformly distributed over the particle volume, was formed.

Similar content being viewed by others

References

V.Yu. Ulianitsky, O.P. Solonenko, A.V. Smirnov, and I.S. Batraev, Detonation spraying of hollow microspherical alumina powder, in: Proc. Inter. Thermal Spray Conf., Barcelona, 2014, No. 3878, P. 668–673.

C. Suryanarayana, Mechanical alloying and milling, Progress in Materials Sci., 2001, Vol. 46, P. 1–184.

V.I. Kotlyarov, V.T. Beshkarev, V.E. Kartsev, V.V. Ivanov, A.A. Gasanov, E.A. Yuzhakova, A.V. Samokhin, A.A. Fadeev, N.V. Alekseev, M.A. Sinayskiy, and E.V. Tretyakov, Production of spherical powders on the basis of group-IV metals for additive manufacturing, Inorganic Materials: Applied Research, 2017, Vol. 8, No. 3, P. 452–458.

A.V. Grigoriev, N.G. Razumov, A.A. Popovich, and A.V. Samokhin, Plasma spheroidization of Nb-Si-based powder alloys obtained by mechanical alloying, Metallurgy and Material Science, St. Petersburg Polytechnical University Journal of Engineering Sciences and Technology, 2017, Vol. 23, No. 1, P. 247–255.

A.E. Chesnokov and A.V. Smirnov, Peculiarities of the formation of the internal structure of cermet particles during plasma treatment, Inorganic Materials, 2019, Vol. 55, No. 4, P. 395–400.

A.E. Chesnokov and A.V. Smirnov, Formation of particle structure during plasma treatment of granulated powder based on titanium, J. Siberian Federal University, Ser. Engineering and Technology, 2019, Vol. 12, No. 2, P. 203–213.

V.A. Poluboyarov, O.P. Solonenko, A.A. Zhdanok, A.E. Chesnokov, and I.A. Pauli, Comparison of the efficiency of mills “AGO-2” and “Activator-2Sl” at the mechanical activation of titanium powder, J. Siberian Federal University, Ser. Engineering and Technology, 2017, Vol. 10, No. 5, P. 646–656.

V.V. Boldyrev, Mechanochemistry and mechanical activation of solids, Russian Chemical Reviews, 2006, Vol. 7, No. 3, P. 177–189.

V.K. Prokudina, V.I. Ratnikov, I.P. Borovinskaya, and A.G. Merzhanov, Refractory Compounds, Kiev, Naukova dumka, 1981, P. 29–34.

N.Z. Lyakhov, T.L. Talako, and T.F. Grigorieva, Effect of mechanical activation on the processes of phase and structure formation during self-propagating high-temperature synthesis, Parallel, Novosibirsk, 2008.

E.G. Avvakumov, Mechanical Methods of Activation of Chemical Processes, Nauka Novosibirsk, 1988.

V.V. Boldyrev, Mechanochemical Synthesis in Inorganic Chemistry, edited by E.G. Avvakumov, Nauka, Novosibirsk, 1991.

M.A. Korchagin, Experimental study of the mechanism of interaction of self-propagating high-temperature synthesis reagents and the development of scientific foundations for obtaining nanocomposite materials with a ceramic hardening phase, Doctoral Dissertation in Tech. Sciences, ISSCM, SB RAS, Novosibirsk, 2007.

G.I. Taylor, The mechanism of plastic deformation of crystals, Proc. Roy. Soc., 1934, Vol. A, No. 145, P. 362–404.

F.P. Bowden and F.H. Thomas, The surface temperature of sliding solids, Proc. Roy. Soc., 1954, Vol. A, No. 223, P. 29–40.

V.V. Kudinov, Plasma Coatings, Nauka, Moscow, 1977.

O.P. Solonenko, Criterion conditions for the formation of hollow microspheres from plasma-treated agglomerated particles, Thermophysics and Aeromechanics, 2014, Vol. 21, No. 6, P. 735–746.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the Russian Science Foundation (Grant No. 19-19-00335), and it was performed using the equipment of the Collective-Use Center “Mechanics” (ITAM SB RAS).

Rights and permissions

About this article

Cite this article

Chesnokov, A.E., Smirnov, A.V. & Vidyuk, T.M. Impact of high-energy effects on the formation of internal structure in copper particles. Thermophys. Aeromech. 27, 607–614 (2020). https://doi.org/10.1134/S0869864320040137

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0869864320040137