Conclusions

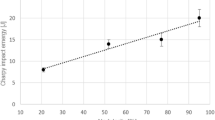

Formation of the ductility characteristics of the powder materials based on iron is associated with the transformation of the porous structure during deformation. The model proposed by Gerland [1] for materials with particles describes accurately the behavior of the material containing pores and links the true strain to fracture with porosity.

The experimental dependence er=F(O) explains satisfactorily the formation of certain important processing characteristics of the material, such as cracking resistance and impact toughness. Since the yield stress of the material produced from various powders differs only slightly in a wide range of porosity, the main contribution to formation of cracking resistance and impact thoughness comes from the true strain to fracture (er).

The difference in the content of the second phase particles in the iron powders of variousggrades leads to differences in the er values for the dense states; er decreases with increasing porosity. Thus, the high values of the impact toughness for the materials produced from WPL-200 and O Cher MK powders are explained by the low content of the second phase particles (1–2%) in comparison with the other materials, where the volume fraction of the particles was 3–5%.

Similar content being viewed by others

Literature cited

G. Gerland and N. M. Parich, “Microstructural aspects of failure of two-phase alloys,” in: Fracture [Russian translation], Vol. 1, Mir, Moscow (1976).

F. McClintock and A. Argon, Deformation and Fracture of Materials [Russian translation], Mir, Moscow (1970).

W. Martin, Micromechanisms of Dispersion Hardening of Alloys [Russian translation], Metallurgiya, Moscow (1963).

A. S. Drachinskii, A. E. Kushchevskii, Yu. N. Podrezov, and A. S. Firstov, “Strain hardening and failure of powder iron,” Poroshk. Metall., No. 10, 78–83 (1984).

I. M. Fedorchenko, V. G. Filimonov, and M. G. Grano, “Problem of the strength and ductility of cermet iron,” Vestn. Mashinostr.,27, No. 8 (1947).

V. T. Troshchenko and V. N. Rudenko, Strength of Cermet Materials and Methods of Determining This Strength [in Russian], Tekhnika, Kiev (1963).

R. A. Andrievskii, “Properties of sintered bodies,” Poroshk. Metall., No. 1, 37–42 (1982).

é. Ch. Pioro, N. Ch. Pioro, V. G. Zherdin, et al., “Examination of the properties of sprayed powders with developed particle form,” Poroshk. Metall., No. 10, 1–7 (1984).

GOST 25281-82, Powder Metallurgy. Methods of Determining the Density of Compacts, Introduced 01.01.81.

M. K. Bernshtein and V. R. Zaimovskii, Structure and Mechanical Properties of Materials [in Russian], Metallurgiya, Moscow (1970).

GOST 9454-78. Methods of Impact Bend Testing at Reduced, Room, and Elevated Temperatures, introduced 01.01.78.

G. T. Hahn and A. R. Rosenfield, ASTM STP, No. 432, Philadelphia (1986), p. 5, cited in: W. Martin, Micromechanisms of Dispersion Hardening of Alloys [Russian translation.], Metallurgiya, Moscow (1983).

A. S. Drachinskii, A. E. Kushchevskii, Yu. N. Podrezov, et al., “Effect of porosity on the cracking resistance of powder iron,” Poroshk. Metall., No. 12, 80–84 (1982).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 10(298), pp. 90–96, October, 1987.

Rights and permissions

About this article

Cite this article

Firstov, S.A., Podrezov, Y.N., Zherdin, A.G. et al. Effect of porosity on the ductility and ductile failure mechanism of powder iron. Powder Metall Met Ceram 26, 855–861 (1987). https://doi.org/10.1007/BF00794374

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00794374