Conclusions

-

1.

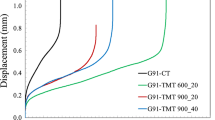

Hydrostatic extrusion of tool steel 9KhS increases the microhardness of martensite, which is highest after tempering at 500°C.

-

2.

The main structural changes occurring in hydrostatically extruded steel 9KhS in the process of tempering at 500°C and favoring retention of high dislocation density during subsequent heating to austenitizing temperature are polygonization and pinning of dislocations by precipitates. Higher tempering temperatures induce recrystallization and thus reduce the effect from hydrostatic extrusion.

Similar content being viewed by others

Literature cited

V. Z. Spuskanyuk, Yu. F. Chernyi, and A. A. Lyadskaya, "Structure and properties of high-speed steels in hydrostatically extruded bars," in: First All-Union Conference on Physics and Technology of High Pressures [in Russian], Donetsk (1973), p. 64.

V. S. Koviko and B. M. Orekhov, in: First Republican Scientific Seminar on the Effect of High Pressures on Substances [in Russian], Inst. Probl. Mater. Akad. Nauk Ukr. SSR, Kiev (1976), p. 108.

L. S. Davydova, Yu. N. Petrov, and B. I. Beresnev, "Effect of hydrostatic extrusion on the structure and properties of Armco iron and steel U8," Fiz. Met. Metalloved.,43, No. 2, 412 (1977).

M. L. Bernshtein, Thermomechanical Treatment of Metals and Alloys [in Russian], Metallurgiya, Moscow (1968).

O. I. Datsko et al., in: First All-Union Conference on Physics and Technology of High Pressures [in Russian], Donetsk (1973), p. 177.

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 3, pp. 28–29, March, 1980.

Rights and permissions

About this article

Cite this article

Brainin, G.É., Dobrikov, A.A. & Osyka, E.I. Effect of postdeformation tempering on the microhardness of martensite in hydrostatically extruded steel 9KhS. Met Sci Heat Treat 22, 192–194 (1980). https://doi.org/10.1007/BF00779599

Issue Date:

DOI: https://doi.org/10.1007/BF00779599