Abstract

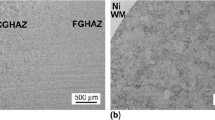

Sometimes post-weld heat treatment (PWHT) is required for stress relieving both the weld metal and heat-affected zone in A517 Quenched and Tempered (QT) steels. This process unavoidably results in further tempering which adversely affects the mechanical properties of the welded joints. Investigations on A517 QT steel are presented in as-welded condition and after PWHT at 560 and 630 °C. Microstructural variation upon applying PWHT and its influence on impact absorbed energy, fatigue behavior, tensile and hardness properties of the material in as-welded condition and after PWHT are studied. The decrease in hardness is very remarkable after PWHT at 630 °C. Increasing heat treatment temperature from 560 to 630 °C results in reduction of YS and UTS. Void coalescence and coarsening of carbides after PWHT makes the fracture easier and results in reduction of absorbed impact energy. Elimination of acicular ferrite after PWHT at 630 °C increases crack growth rate, and fatigue endurance limit is reduced.

Similar content being viewed by others

References

R. Datta, D. Mukerjee, S. Jha, K. Narasimhan, and R. Veeraraghavan, Weldability Characteristics of Shielded Metal Arc Welded High Strength Quenched and Tempered Plates, J. Mater. Eng. Perform., 2002, 11, p 5–10

E.J. Czyryca, D.P. Kihl, and R. DeNale, Meeting the Challenge of Higher Strength, Lighter, Affordable Warships, AMPTIAC Q., 2003, 7, p 63–70

P. Phetlam and V. Uthaisangsuk, Microstructure Based Flow Stress Modeling for Quenched and Tempered Low Alloy Steel, Mater. Des., 2015, 82, p 189–199

X. Deng and D. Ju, Modeling and Simulation of Quenching and Tempering Process in Steels, Phys. Proc., 2013, 50, p 368–374

G. Magudeeswaran, V. Balasubramanian, and G.M. Reddy, Effect of Welding Processes and Consumables on Fatigue Crack Growth Behaviour of Armour Grade Quenched and Tempered Steel Joints, Def. Technol., 2014, 10, p 47–59

Y. Sun, J. Chen, and J. Liu, Effect of Hydrogen on Ductility of High Strength Quenched and Tempered (QT) Cr Ni Mo Steels, Mater. Sci. Eng., A, 2015, 625, p 89–97

R. Sepehrzad, E.H. Dehkordi, A. Shafiei, A.A. Aqda, and A. Estiri, Effect of Stress Relieving on Mechanical and Metallurgical Properties of Shielded Metal Arc Welded Joints of A517 Steel, Int. J. ISSI, 2015, 12(2015), p 21–27

Z. Sterjovski, D.P. Dunne, and S. Ambrose, Evaluation of Cross-Weld Properties of Quenched and Tempered Pressure Vessel Steel Before and After PWHT, Int. J. Press. Vessel Pip., 2004, 81, p 465–470

D. Radaj, C.M. Sonsino, and D. Flade, Prediction of Service Fatigue Strength of a Welded Tubular Joint on the Basis of the Notch Strain Approach, Int. J. Fatigue, 1998, 20, p 471–480

T.L. Teng, C.P. Fung, and P.H. Chang, Effect of Residual Stresses on the Fatigue of butt joints using thermal elasto-plastic and Multiaxial Fatigue Theory, Eng. Fail. Anal., 2003, 10(2003), p 131–151

V. Balasubramanian, B. Guha, A.S.J. Swamidas, and R. Seshadri, Influences of Shielded Metal Arc Welded Cruciform Joint Dimensions on Toe Crack Failures of Pressure Vessel Grade Steels, Eng. Fail. Anal., 2000, 7, p 169–179

M.S. Zhao, S.P. Chiew, and C.K. Lee, Post Weld Heat Treatment for High Strength Steel Welded Connections, J. Constr. Steel Res., 2016, 122, p 167–177

K.H. Lee, M.J. Jhung, M.C. Kim, and B.S. Lee, Effects of Tempering and PWHT on Microstructures and Mechanical Properties of SA508 GR.4 N Steel, Nucl. Eng. Technol., 2014, 46, p 413–422

W. Guo, S. Dong, J.A. Francis, and L. Li, Microstructure and Mechanical Characteristics of a Laser Welded Joint in SA508 Nuclear Pressure Vessel Steel, Mater. Sci. Eng., A, 2015, 625, p 65–80

M.O.O’Brien, R.F.Lumb, Effect of Repeated Post Weld Heat Treatment Cycles on Properties of a Quench and Tempered Pressure Vessel Plate. Australas. Weld. J. 45 (2000) 45

K. Horikawa, S. Fukuda, and Y. Kishimoto, Fatigue Crack Growth Rate in Welded Joints After Stess Relief Heat Treatment, Trans. JWRI, 1981, 10, p 219–231

W.A. Logsdon, The Influence of Long-Time Stress Relief Treatments on the Dynamic Fracture Toughness Properties of ASME SA508 C1 2a and ASME SA533 Gr B C1 2 Pressure Vessel Steels, J. Mater. Energy Syst., 1982, 3, p 39–50

Method of Repeated Tension Fatigue Testing for Fusion Welded Joint, JIS Z3103. (Japanese Industrial Standard, Japanese Standard Association, 1987)

ASTM, Charpy V-Notch, ASTM E23-06 Standard Methods for Impact Tests on Metals, Philadelphia, 1999.

J. Nicholas, Are Quenched and Tempered (Q & T) Steels Readily Weldable? (TWI, 2002), p 1-2.

ASM Handbook, vol 11, 9th edn. (American Society for Metals, 1989), p. 102–135

C.S. Lee, R.S. Chandel, and H.P. Seow, Effect of Welding Parameters on the Size of Heat Affected Zone of Submerged Arc Welding, Mater. Manuf. Process., 2000, 15, p 649–666

H. Bhadeshia, Design of Ferritic Creep Resistant Steels, ISIJ Int., 2001, 41, p 626–640

ASME, Section IX, Qualification standard for welding and brazing procedures, welders, brazers, and welding and brazing operators, 2007, p 72–127.

Australian Standard 3597, AS3597-1997. Structural and Pressure Vessel Steel-Quenched and Tempered Plate, 1997.

A. Bensely, L. Shyamala, S. Harish, D. Mohan Lal, G. Nagarajan, K. Junik, and A. Rajadurai, Fatigue Behaviour and Fracture Mechanism of Cryogenically Treated En 353 Steel, Mater. Des., 2009, 30, p 2955–2962

S. Kang and S.J. Lee, Prediction of Tempered Martensite Hardness Incorporating the Composition-Dependent Tempering Parameter in Low Alloy Steels, Jpn. Inst. Metals Mater. Mater. Trans., 2014, 55, p 1069–1072

R. Honeycombe and H. Bhadeshia, Steels: Microstructures and Properties, 2nd ed., Edward Arnold, London, 1995

G. Magudeeswaran, V. Balasubramanian, G. Madhusudhan Reddy, and T.S. Balasubramaian, Effect of Welding Processes and Consumables on Tensile and Impact Properties of High Strength Quenched and Tempered Steel Joints, J. Iron. Steel Res. Int., 2008, 15, p 87–94

K.H. Lee, S.G. Park, M.C. Kim, B.S. Lee, and D.M. Wee, Characterization of Transition Behavior in SA508 Gr.4 N Ni-Cr-Mo Low Alloy Steels with Microstructural Alternation by Ni and Cr Contents, Mater. Sci. Eng., A, 2011, 529, p 156–163

K.H. Lee, S.G. Park, M.C. Kim, and B.S. Lee, Cleavage Fracture Toughness of Tempered Martensitic Ni-Cr-Mo Low Alloy Steel with Different Martensite Fraction, Mater. Sci. Eng., A, 2012, 534, p 75–82

J. Maciejewski, The Effects of Sulfide Inclusions on Mechanical Properties and Failures of Steel Components, J. Fail. Anal. Prev., 2015, 15, p 169–178

H. Zakerinia, A. Kermanpur, and A. Najafizadeh, Color Metallography; A Suitable Method for Characterization of Martensite and Bainite in Multiphase Steels, International Journal of ISSI., 2009, 6, p 14–18

ASM Handbook, American Society for Metals, 9th ed. Vol.6, 1983.

R.A. Howell, G.S.Barritte, The nature of acicular ferrite in HSLA steel weld metals, J Mat Sci. 17 (1985) 732-740.

K.S. Chan, P. Yi-Ming, D. Davidson, and R.C. McClung, Fatigue Crack Growth Mechanisms in HSLA-80 Steels, Mater. Sci. Eng., A, 1997, 222, p 1–8

S. Begum, D.L. Chen, S. Xu, and A.A. Luo, Strain-Controlled Low Cycle Fatigue Properties of a Newly Developed Extruded Magnesium Alloy, Metall. Mater. Trans. A, 2008, 39A, p 3014–3026

S. Begum, D.L. Chen, S. Xu, and A.A. Luo, Effect of Strain Ratio and Strain Rate on Low Cycle Fatigue Behavior of AZ31 Wrought Magnesium Alloy, Mater. Sci. Eng., A, 2009, 517, p 334–343

J. Hu, L.X. Du, M. Zang, S.J. Yin, Y.G. Wang, X.Y. Qi, X.H. Gao, and R.D.K. Misra, On the Determining Role of Acicular Ferrite in V-N Microalloyed Steel in Increasing Strength-Toughness Combination, Mater. Charact., 2016, 118, p 446–453

J. Wang and Y.J. Li, Microstructure Characterization in the Weld Metals of HQ130 QJ63 High Strength Steels, Bull. Mat. Sci., 2003, 36, p 35–39

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rabiei, A., Derakhshandeh-Haghighi, R. Studying the Effect of PWHT on Microstructural Evolution and Mechanical Properties of Welded A517 Quenched and Tempered Steel. J. of Materi Eng and Perform 26, 4567–4577 (2017). https://doi.org/10.1007/s11665-017-2868-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2868-3