Abstract

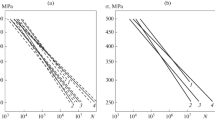

Results are given of an investigation of the effectiveness of a method of strengthening the working titanium alloy blades of a gas turbine engine compressor. It is established that the proposed strengthening method can lengthen to more than double the service life of damaged blades. In addition it is shown that in these blades, in comparison with nonstrengthened blades, cracks develop in a narrower zone and predominantly on the side of the inlet edge.

Similar content being viewed by others

Literature cited

V. A. Boguslaev, I. A. Birger and N. I. Obodan, Method of manufacturing titanium blades of gas turbine engines. Affirmative decision on statement 4907407/27. Accepted 05.29.91.

OST l320-1-304-79. Gas turbine engine blades. Normalization of compressor blade damage caused by blows from external 320-2cts. Introduced 07.07.91.

OST 1.00.320-377. Gas turbine engine blades (GEB). Fatigue testing methods. Introduced 07.01.78.

Author information

Authors and Affiliations

Additional information

Translated from Problemy Prochnosti, No. 4, pp. 45–49, April, 1992.

Rights and permissions

About this article

Cite this article

Boguslaev, V.A. Possibility of increasing the service life of damaged blades. Strength Mater 24, 317–320 (1992). https://doi.org/10.1007/BF00777351

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00777351