Conclusions

-

1.

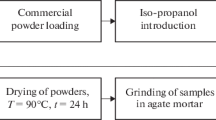

We have proposed a new method for preparing specimens for the microstructural investigation of individual particles of the powder; this method can be used to study the dimensions, form, and structure of particles in a state close to the initial state.

-

2.

We have shown that the structure of particles of a powder of the same material is determined by the method of preparation and the subsequent treatment conditions. Using iron powder from the Sulin plant as an example, we have shown that particles of the same powder can be heterogeneous with regard to structure.

-

3.

These features in the structures of powder particles prepared by various methods and under various treatment conditions must be taken into account when making components of powders with given properties.

Similar content being viewed by others

Literature cited

F. V. Lenel, H. D. Ambs, and E. O. Lomerson, Symposium on Powder Metallurgy, 1954 (London, 1956), pp. 90–96.

F. Eisenkolb, Powder Metallurgy [Russian translation] (Metallurgizdat, Moscow, 1959).

Z. Delisle, Journal of Metals (Trans. AIME),1, 3, 228–232 (1949).

R. I. Garber and S. S. D'yachenko, ZhTF,22, 7, 1097 (1957).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Aksenov, G.I., Minaev, E.M. & Strizhekova, Z.I. A microstructural investigation of particles of metal powders. Powder Metall Met Ceram 1, 160–164 (1963). https://doi.org/10.1007/BF00775073

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00775073