Conclusions

-

1.

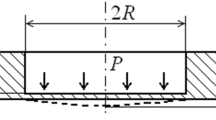

The diffusion of hydrogen out of specimens of commercial iron and steel 40KhN is analogous to the process of heat transfer, and is controlled by two parameters: The hydrogen diffusion coefficient, and the parameter (α/λ)H which characterizes the rate of evolution of hydrogen from the surface.

-

2.

With increasing temperature at the surface of specimens of commercial iron and steel 40KhN the value of (α/λ)H decreases — most rapidly in specimens of commercial iron.

-

3.

Differing effects of temperature on increase of hydrogen diffusion coefficient and decrease of the parameter (α/λ)H lead in steel 40KhN to a higher rate of evolution of hydrogen at 200–300°C than at 400°C.

-

4.

The concentration of hydrogen at the surface of specimens of commercial iron is lowest at 400°C, and increases with increasing temperature. The concentration of hydrogen at the surface of steel 40KhN is higher at 300–400°C because of hydrogen residing in the interphase boundaries. The portion of such hydrogen decreases with temperature and, as a result, the total concentration of hydrogen decreases.

Similar content being viewed by others

Literature Cited

A. A. Astaf'ev, "Effective heat-treatment regimes for large forgings after working", Metalloved. Term. Obrab. Met., No. 5, 2–7 (1962).

A. A. Astaf'ev, "Preliminary heat treatment of forgings", Metalloved. Term. Obrab. Met. No. 9, 2–6 (1978).

A. A. Astaf'ev, "Hydrogen embrittlement of structural steels", Metalloved. Term. Obrab. Met., No. 2, 2–7 (1984).

S. Kazeev, Kinetics Applied to Metallurgy, [in Russian], Oborongiz, Moscow (1956).

G. T. Batalin, Tr. Inst. Chern. Met., Vol. 4, Akad, Nauk UkrSSR, Kiev (1950).

N. M. Chuiko, "Removal of hydrogen from solid steel by diffusion", Steel, No. 6, 487–493 (1951).

J. D. Hobson, J. Iron Steel Inst., No. 8, (1951).

J. D. Hobson, J. Iron Steel Inst.,32, No. 6, 245–249 (1959).

P. V. Sklyuev, Hydrogen and Flakes in Large Forgings [in Russian], Mashgiz, Moscow (1963).

P. V. Sklyuev, "Calculation of antiflake treatment," Metalloved. Term. Obrab. Met., No. 5, (1962).

Additional information

Scientific-Production Organization "TsNIITMASH." Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 2, pp. 5–8, February, 1991.

Rights and permissions

About this article

Cite this article

Astaf'ev, A.A. Diffusion and evolution of hydrogen from steel. Met Sci Heat Treat 33, 93–96 (1991). https://doi.org/10.1007/BF00773879

Issue Date:

DOI: https://doi.org/10.1007/BF00773879