Abstract

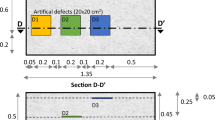

The corrosion-induced material loss in crude oil carrying steel pipelines was originally studied by making use of the backscatter X-ray technique. The steel thickness can be determined by studying the density profile of the backscatter intensity vs. the depth location of a “voxel.” There are, however, some practical limitations to the above method, and a new method for evaluating steel thickness, namely, the “transcatter” technique is described. This technique uses the intensity of the beam which is transmitted by the pipe wall and subsequently scattered by the hydrocarbon inside the pipeline. The thickness is evaluated using three techniques, namely, the “sequential” technique, the “dual angle” technique, and the “reference” technique. Of the three techniques, the sequential technique has been studied in detail. The mathematical equations and experimental results related to the transcatter technique show that the thickness can be measured with an accuracy of better than 10% for a nominal steel thickness of 8 mm with a measurement time of several minutes.

Similar content being viewed by others

References

P. W. Lott and J. Lott, Near real-time radiologic corrosion monitoring of Arctic petroleum gathering lines,Mater. Eval. 43:408–412 (1985).

Graeme, Jr., J. F. Singer, and Raimund Mayer, Wall thickness and material loss Measurements from two dimensional digital radiographs, inReview of Progress in Quantitative NDE (University of California at San Diego, La Jolla, CA, July 19–24, 1992).

J. Kosanetzky, G. Harding, K. H. Fischer, and A. Meyer, Compton backscatter tomography of low atomic number materials with the COMSCAN system, inTechnical Information Bulletin (Philips Industrial X-Ray Supply Center, Hamburg, 1988).

G. Harding, On the sensitivity and application possibilities of a novel Compton scatter imaging system,IEEE Trans. Nuclear Sci. NS-29 (3) (June 1982).

G. Harding, H. Strecker, and R. Tischler, X-ray imaging with Compton-scatter radiation,Philips Tech. Rev. 41:46 (1983/84).

H. Strecker, Scatter imaging of aluminum castings using an X-ray fan beam and a pinhole camera,Mater. Eval. 40:1050–1056 (1982).

A. Uhrberg, Indicating Corrosion Under Insulation with X-ray Backscatter. Thesis, MS degree in Mechanical Engineering, University of Houston, Houston, Texas (1991).

R. H. Bossi, K. D. Friddell, and J. M. Nelson, Backscatter X-ray imaging,Mater. Eval. 46:1462–1467 (1988).

W. L. Anderson, P. S. Ong, and Feng Qiu, Deconvolution of X-ray backscatter diffraction for NDE of corrosion, inReview of Progress in Quantitative NDE (University of California at San Diego, La Jolla, CA, July 1992), pp. 19–24.

P. S. Ong, Material Losses in Steel Pipes Under Insulation, Report under contract No. F07-C1080L, Exxon Research and Engineering (1991).

A. Vishwanath, Study of a Thickness Probe for Steel Using Backscattered X-Rays. Thesis, MS degree in Electrical Engineering, University of Houston, Houston, Texas (1991).

P. S. Ong, W. L. Anderson, B. D. Cook, and R. Subramanyan, Transcatter for NDE of Insulated, oil carrying pipelines, inReview of Progress in Quantitative NDE (University of California at San Diego, La Jolla, CA, July 1992), pp. 19–24.

J. H. Hubbell, Photon Cross Sections, Attenuation Coefficients and Energy Absorption Coefficients from 10 KeV to 100 GeV, NSRDS-NBS 29 (1969).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ong, P.S., Anderson, W.L., Cook, B.D. et al. A novel X-ray technique for inspection of steel pipes. J Nondestruct Eval 13, 165–173 (1994). https://doi.org/10.1007/BF00742582

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00742582