Abstract

Research projects on innovative structural materials carried out at the University “La Sapienza” of Rome in the last years are described. Problems, objectives and future developments are reported on new Al-Li-Mg-Ce alloys, SiC reinforced titanium and aluminum composites, ceramic composites for fuel engines, structural polymer composites, modelling and simulation procedures with new experimental testing methods for composite components.

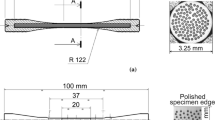

Particularly, Al-Li (2–2.8%)−Mg(2%)−Ce(0.5–0.8%) alloys were studied for their very low density (less than 2.5 kg/d3), and good mechanical properties, especially fatigue resistance, and reasonable production cost.

Plasma spray technique was used to produce SiC-fiber reinforced titanium alloys (Ti-6AI-4V), or pure aluminium, matrices. Squeeze-casting method was also used for SiC-particles reinforced aluminium alloys composites.

As new synthetic ceramics, SiC-additivated Al2O3−MgO (ZrO2, Y2O3) were prepared for fuel engines applications. For testing of this material a new high pressure fretting wear rig was developed.

Curing agents for epoxy resin matrices were examined from the point of view of mechanical properties and durability of glass, or carbon, reinforced polymer composites. In testing of materials, especially structural composite components, new methods based on acoustic emission, image analysis, thermography (for polymer composites), ultasonic waves etc. were joined to classical tensile or impact tests to evaluate the damage intensity in real time. Al-electrocoated stainless steels and Superalloys were studied for high temperature oxidation and thermal cycling resistance.

Beta-metastable titanium alloys were also examined.

Similar content being viewed by others

References

Buttinelli, D., Felli, F., Lupi, C., and Marani, F. 1992. Effect of Cerium Addition on Grain Size and Recrystallization of Al-Li-Mg Alloys.Mater. Sci. Forum, 94/96, 771–778.

Buttinelli, D., Felli, F., Lupi, C., and Marani, F., Structure and Mechanical Properties of New Al-Li-Mg-Ce Alloys.Proc. of 6th Int. Al-Li Conference (Peter, M., Winkler, P.J., Eds.), Verlag, Berlin, 433–438, 1992.

Effect of Ce, Nd and Y Alloying Additions on the Mechanical Properties of Al-Li-Mg Base Alloys., in Light Materials for Transportation Systems (Kim, N.J.Ed.), CAAM-PUST, Pohang (Korea), 141–149, 1993.

Cavallini, M., Felli, F., and Delogu, P.: Composite Fracture in Al-Li-Cu Alloy.Metall. Sci. Technol., 9 (1), 3–9, 1991.

Cavallini, M., and Felli, F., Fatigue, Toughness and Delamination in a 8090 Al-Li Alloy.Proc. of 6th Int. Al-Li Conference (Peters, M., Winkler, P.J. Eds.), Verlag, Berlin, 627–631, 1992.

Cavallini, M., Iacoviello, F., and Felli, F., Propagation of fatigue crack in a 8090 Al-Li alloy (in Italian),Atti IX Convegno Naz. Gruppo Italiano Frattura, Roma, 171–179, 1993.

Marchetti, M., Torelli, A., Milella, P.P., and Pini, A. 1992. Crack Propagation and Arrest in Aluminium Alloys for Aerospace Use,Proc. of 17th M.P.A. Seminar, Stuttgart, 8.1–20.

Buttinelli, D., and Felli, F., unpublished work.

Valente, T., and Carassiti, F., Fabrication of aluminium matrix monotapes strengthened with continuous fibres by plasma spraying in controlled environment,Proc. of 24th ISATA on “New and Alternative Materials for the Automotive Industries”, Florence, 311–318, 1991.

Valente, T., et al., Fabrication of Aluminium matrix Composites by Plasma Spray and Secondary Techniques of Consolidation, Presented to2nd Plasma Techniques Symposium, Luzern, June 1991.

Bartuli, C., Carassiti, F., Turriziani, R., and Valente, T.,Manufacture and Characterization of Continuous SiC Fibre Reinforced Aluminium Matrix Composites by Low Pressure Plasma Spraying in Composite Materials (Di Benedetto, A.T. et al., Eds) Elsevier, 259–271, 1992.

Valente, T., and Bartuli, C. 1993. A plasma spray process for the manufacture of fibre reinforced Ti-6A1-4V composite monotapes,Journal of Thermal Spray Technology, 2(4).

Bonora, N., Costanzi, M., Marchetti, M., and Newaz, G.M. Micro-damage Effects on the Overall Response of Long Fibre Metal Matrix Composites. (B) Macrobehaviors and Interfacial Phenomena Correlation in Metal matrix Composites,Proc. of Int. Conference on “Interfacial Phenomena in Composite Materials”, Cambridge (UK), 1993 (in press).

Proverbio, E., Rossi, D., and Cigna, R. 1992. Influence of water vapour on high temperature oxidation of Al2O3−MgO doped hot pressed silicon nitride,J. Europ. Ceram. Soc., 9, 453–458.

Proverbio, E., Carassiti, F., Favuzzi, G., and Valente, T., An experimental study of the hot oxidation with humidified air of HPSN additivated with MgO-Al2O3, ZrO2−Al2O3 and Y2O3−Al2O3,Materials Engineering (in press).

Carassiti, F., Proverbio, E., Valente, T., McColl, I., and Millman, R.S. 1992. Fretting wear of fine ceramics under extreme conditions. A design study on a dedicated fretting wear rig,Proc. of 8th SIMCER, Rimini, (in press).

Maura, G., and Rinaldi, G. 1990. Room Temperature Hardening of Epoxy Composites with Tailored Curing Agents, Materials Engineering, 1 (1), 181–188.

Rinaldi, G., and Maura, G. 1993. Durable Glass-Epoxy Composites Cured at low Temperatures, Effect of thermal Cycling, UV Irradiation and Wet Environment,Polymer International, 31, 339–345.

Rinaldi, G., and Rossi, D. 1993. Particulate Composites from Epoxy Resins and Fly-ash for the confinement of Radwastes,Polymer International, 31, 227–233.

DiVita, G., Marchetti, M., Moroni, P., and Perugini, P. 1992. Designing complex shape filament-wound structures.Composite Manufacturing, 3, 53–58.

Amaldi, A., and Marchetti, M. 1992. Fracture stresses of filament wound tubes under uniaxial and biaxial loads.Proc. of International Council of Aeronautical Sciences (ICAS) Conference, Beijing, 1672–1677.

Caneva, C., Marchetti, M., and Bonora, N. 1991. Structural Control and Characterization of Advanced Composite Laminates by Acoustic Emission,Proc. of 24th Int. Symp. on Automotive Technology and Automation, Florence, 267–286.

Caneva, C., Santulli, C., and Stivali, F. 1993. Stress Field in filament Wound Pressure Vessel during the Hydraulic Test (in Italian).Atti IX Convegno Nazionale Gruppo Italiano Frattura, Rome, 381–394.

Caneva, C., Franciosa, A., Mazzola, M., and Santulli, C. 1992. Quality Inspection on Filament Wound Pressure Vessels by Acoustic Emission (in Italian),Atti VIII Convegno Nazionale Gruppo Italiano Frattura, Genua, 289–297.

Caneva, C., Olivieri, S., Santulli, and C. Bonifazi, G. 1993. Impact Damage Evaluation on Advanced Stitched Composites by means Acoustic Emission and Image Analysis,Composite Structures, 25, 121–128.

Bonora, N., La Barbera, A., Marchetti M. and Milella, P. 1993 Experimental verification and theoretical simulation of fracture behavior of composite materials.Composite Structures, 23, 87–97.

Barboni, R., and Gaudenzi, P., A class of C° finite elements for the static and dynamic analysis of laminated plates,Computers & Structures, 44, 1169–1178, 1992.

Gaudenzi, P.: A general formulation of higher order theories for the analysis of laminated plates.Composite Structures, 20, 103–112, 1992.

Barboni, R., Gaudenzi, P., and Mannini, A.: The parameter-transfer finite element for structural analysis.AIAA Journal, 31, 923–929, 1993.

Bonora, N., Costanzi, M., and Marchetti, M. 1993. On Closed Form Solution for the Elastic Stress Field Around Holes in Orthotropic Composite Plates under in-plane stress conditions.Composite Structures, 25, 139–156.

Bernabai, U., Felli, F., Capuano, G. A., Dang, A., and Di Gianfrancesco, A. 1992. High Temperature Air Oxidation of an Aluminum Electro-plated Ni-based Superalloy for Turbine Blades,Proc. of Int. Conference on Materials Development in Transportation, Genua, v. 1, 267–274.

Capuano, G.A., Dang, A., Bernabai, U., and Felli, F. 1993. High Temperature Oxidation and Thermal Cycling of Aluminum-Electroplated Stainless Steels,Oxidation of Metals, 39, 263–279.

Buttinelli, D., Felli, F., and Festa, G. 1991. Evaluation of the mechanical behavior of a beta-C titanium alloy in aged and overaged condition,Metall. Sci. Techn., 9, 117–125.

Buttinelli, D., Felli, F., Festa, G., and Querales, A.J. 1992. Effect of Heat Treatments on Fatigue Behavior of a Beta-C Titanium Alloy.Proc. of 7th World Conference on Titanium, S. Diego, (in press).

Buttinelli, D., Felli, F., and Festa, G. 1993. Mechanical Behavior of an Experimental Beta-Titanium Alloy. Proc. ofInt. Symposium on Metallurgy and Technology of Practical Titanium Alloys, Chiba (Japan), v. 2, 1765–1770.

Author information

Authors and Affiliations

About this article

Cite this article

Buttinelli, D. Research on innovative materials at the University “La Sapienza”. Adv Perform Mater 1, 183–195 (1994). https://doi.org/10.1007/BF00713730

Issue Date:

DOI: https://doi.org/10.1007/BF00713730