Abstract

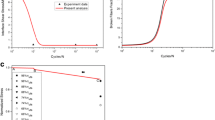

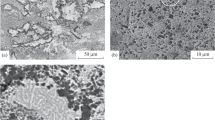

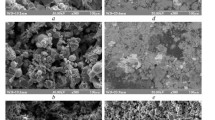

Critical stress intensity factor, and related parameters have been measured in three-point bending for 18 different combinations of different volume fractions of cobalt (5 to 37%) and grain size of tungsten carbide (0.7, 1.1 and 2.2 μm). In particular, a study was made of the correlations between the strength and mechanical and microstructural parameters, such as ¯L Co,C WC, ¯L Co/¯D WC, ¯L 2Co /¯D WC,H V and wear resistance. A hypothesis for the mechanism of fracture has been proposed following an analysis of these results and a study of the mode of fracture.

Similar content being viewed by others

References

S. S. Yen, M.S. Thesis, Lehigh University (1971).

J. L. Chermant, A. Deschanvres andA. Iost,Mat. Res. Bull. 8 (1973) 925.

Idem; in “Fracture Mechanics of Ceramics”, edited by R. C. Bradt, D. P. H. Hasselman and E. F. Lange, (Plenum Press, New York, 1974) p. 347.

R. C. Lueth,ibidin “, Vol. II (1974) p. 791.

F. Osterstock, Diplôme d'Etudes Approfondies, Caen (1974).

N. Ingelström andH. Nordberg,Eng. Fract. Mech. 6 (1974) 597.

T. Johannesson, 4th European Symposium for Powder Metallurgy, Grenoble, 13–15 May 1975, no. 5–11.

J. L. Chermant, F. Osterstock andR. Meyer,ibid, no. 5–12.

S. A. Saltykov, “Stereometric Metallography” (Metallurgizdat, Moscow, 1958).

M. Coster, Thèse de Doctorat ès-Sciences, Caen, (1974).

M. Drouzy.Prakt. Metal. 9 (1967) 481.

Proposed recommended practice for plane-strain fracture toughness testing of high-strength metallic materials using a fatigue-cracked bend specimen,A.S.T.M Standards 31 (1968) 1018.

Norme A.F.N.O.R., A 03-180, (February 1974).

W. F. Brown andJ. E. Srawley, A.S.T.M.-S.T.P. 410 (1967).

R. P. Felgar andJ. D. Lubahn,Trans. Soc. Test. Mat. 57 (1957) 770.

H. Doi, Y. Fujiwara, K. Mikaye andY. Oosawa.Met. Trans,1 (1970) 1417.

G. R. Irwin,J. Appl. Mech. 24 (1957) 361.

R. Pabst,Z. Werkstofftechnik 6 (1975) 17.

R. W. Davidge andG. Tappin,J. Mater. Sci. 3 (1968) 165.

J. Nakayama,J. Amer. Ceram. Soc. 48 (1965) 583.

F. Osterstock, Thèse d'Ingénieur Docteur, Caen, (1975).

J. L. Chermant, A. Iost andF. Osterstock,Proc. Brit Ceram. Soc. 25 (1975) 197.

J. L. Chermant, M. Coster andA. Deschanvres,Metallogr. 8 (1975) 271.

Idem, ibid 9 (1976) 199.

H. Doi, Y. Fujiwara andY. Oosawa, Proceedings of the International Conference on Mechanical Behavior of Materials, Vol. V (The Society of Materials Sciences, Japan, 1972) p. 207.

J. Gurland,Trans. Met. Soc. AIME 227 (1963) 1146.

F. R. N. Nabarro andS. B. Luyckx,Trans. J. Inst. Met. 9 suppl. (1968) 610.

J. C. Fisher, E. W. Hart, R. H. Pry,Acta Met. 1 (1953) 336.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chermant, J.L., Osterstock, F. Fracture toughness and fracture of WC-Co composites. J Mater Sci 11, 1939–1951 (1976). https://doi.org/10.1007/BF00708272

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00708272