Abstract

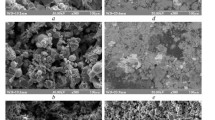

The structure, chemical and phase compositions, hardness, and wear resistance of a Cu–Ti–Al–Ni–Fe–C–B composite prepared by self-propagating high-temperature synthesis (SHS) have been studied. The matrix was formed by Сu–8.5Al–5.0Ni–4.0Fe–1.0Si–0.2Cr aluminum bronze. The powders of Ti, C, and B4C were used for synthesis. The composite matrix is shown to be a copper-based solid solution, which contains eutectic (Cu + (Ni,Fe)Al) regions with the microhardness of 900 HV 0.1. The strengthening phases are TiC and TiB2. The microhardness of (γ + TiC) regions is 550 HV 0.1, and that of (Cu + TiB2 + TiC) regions is 700 HV 0.1. The integral hardness of the composite is 62 HRC. The (γ + TiC) regions are the most plastic structural component of the composite, which are characterized by a high maximum indentation depth, the total mechanical work of indentation and a component of plastic indentation work (φ), and indentation creep (СIT). Abrasive wear results in cut-off of the surface layers of the structural components (Cu + TiC) and (Cu + (Ni,Fe)Al) with the formation of a smooth surface. The roughness of the sample surface does not exceed 2.8 μm.

Similar content being viewed by others

REFERENCES

A. G. Merzhanov, Solid Flame Combustion (ISMAN, Chernogolovka, 2000) [in Russian].

A. P. Amosov, I. P. Borovinskaya, and A. G. Merzhanov, Powder Metallurgy of Self-Propagating High-Temperature Synthesis of Materials (Mashinostroenie, Moscow, 2007) [in Russian].

X. Zhang, N. Liu, C. Rong, and J. Zhou, “Microstructure and mechanical properties of TiC–TiN–Zr–WC–Ni–Co cermets,” Ceram. Int. 35, 1187–1193 (2009).

J. S. Kim, D. V. Dudina, J. C. Kom, Y. S. Kwon, J. J. Park, and C. K. Rhu, “Properties of Cu-based nanocomposites produced by mechanically-activated self-propagating high-temperature synthesis and spark–plasma sintering,” J. Nanosci. Nanotechnol. 10, 252–257 (2010).

O. N. T. Yoang, V. N. Hoang, J. S. Kim, and D. V. Dudina, “Strucrural investigation of TiC–Cu nanocomposites prepared by ball milling and spark plasma sintering,” Metals 7, 123 (2017).

B. A. Kolachev, V. I. Elagin, and V. A. Livanov, Metal Science and Heat Treatment of Non-Ferrous Metals and Alloys (MISiS, Moscow, 2005) [in Russian].

A. M. Zakharov, Phase Diagram of Binary and Ternary Systems (Metallurgiya, Moscow, 1990) [in Russian].

Yu. I. Golovin, Nanoindentation and its Possibilities (Mashinostroenie, Moscow, 2009) [in Russian].

A. Leyland and A. Matthews, “On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimized tribological behavior,” Wear 246, 1–11 (2000).

S. V. Smirnov, N. B. Pugacheva, A. V. Tropotov, and A. N. Soloshenko, “Resistance to deformation of structural constituents of a high-alloy brass,” Phys. Met. Metallogr. 91 (2), 210–219 (2001).

S. V. Smirnov, N. B. Pugacheva, A. N. Soloshenko, and A. V. Tropotov, “Plastic deformation of a high-alloy brass,” Phys. Met. Metallogr. 93 (6), 91–100 (2002).

S. V. Smirnov and E. O. Smirnova, “A technique for determining coefficients of the “stress–strain” diagram by nanoscratch test results,” J. Mater. Res. 28, 1730–1736 (2014).

I. A. Veretennikova, N. B. Pugacheva, E. O. Smirnova, and N. S. Michurov, “Laser welding of titanium alloy VT1-0 and steel 12Kh18N10T with an intermediate copper insert,” Pis’ma Mater. 8 (1), 42–47 (2018).

S. Smirnov, M. Myasnikova, and N. Pugacheva, “Hierarchical simulation of plastic deformation and fracture of complexly alloyed brass,” Int. J. Damage Mech. 25, 251–265 (2016).

L. M. Rybakova and L. I. Kuksenova, Structure and Wear Resistance of Metal (Mashinostroenie, Moscow, 1983) [in Russian].

N. B. Pugacheva, Yu. V. Nikolin, E. I. Senaeva, and I. Yu. Malygina, “Structure of Fe–Ni–Ti–C–B SHS composites,” Phys. Met. Metallogr. 120 (11), 1078–1084 (2019).

B. V. Nikolin, M. B. Matevosyan, S. P. Kochugov, and N. B. Pugacheva, RF Patent No. 2680489 (2017).

N. B. Pugacheva, Tu. V. Nikolin, I. Yu. Malygina, and E. B. Trushina, “Formation of the structure of Fe–Ni–Ti–C–B composites under self-propagating high-temperature synthesis,” AIP Conf. Proc. 2053, 020013 (2018). https://doi.org/10.1063/1.5084359

N. B. Pugacheva, Yu. V. Nikolin, and E. I. Senaeva, “The structure and wear resistance of a Ti–Ni–Fe–C–B composite,” AIP Conf. Proc. 2176, 020007 (2019). https://doi.org/10.1063/1.5135119

GOST R 8.748–2011 (ISO 14577–1: 2002) Metals and Alloys. Measurement of Hardness and Other Characteristics of Materials During Instrumental Indentation (Standartinform, Moscow, 2012), p. 32 [in Russian].

M. I. Petrzhik and E. A. Levashov, “Modern methods for investigating functional surfaces of advanced materials by mechanical contact testing,” Crystallogr. Rep. 52, 966–974 (2007). https://doi.org/10.1134/S1063774507060065

Y. T. Cheng and C. M. Cheng, “Relationships between hardness, elastic modulus, and the work of indentation,” Appl. Phys. Lett. 73, 614–616 (1998). https://doi.org/10.1063/1.121873

P. H. Mayrhofer, C. Mitterer, and J. Musil, “Structure-property relationships in single- and dual-phase nanocrystalline hard coatings,” Surf. Coat. Technol. 174–175, 725–731 (2003). https://doi.org/10.1016/S0257-8972(03)00576-0

A. V. Makarov, L. G. Korshunov, I. Yu. Malygina, and A. L. Osintseva, “Effect of laser quenching and subsequent heat treatment on the structure and wear resistance of a cemented steel 20KhN3A,” Phys. Met. Metallogr. 103 (5), 507–518 (2007).

A. V. Makarov, E. S. Gorkunov, L. Kh. Kogan, I. Yu. Malygina, and A. L. Osintseva, “Eddy-current testing of the structure, hardness and abrasive wear resistance of laser-hardened and subsequently tempered high-strength cast iron,” Diagn., Resour. Mech. Mater. Struct., No. 6, 90–103 (2015). https://doi.org/10.17804/2410-9908.2015.6.090-103

R. A. Savrvi, P. A. Skorynina, A. V. Makarov, and A. L. Osintseva, “Effect of liquid carburizing at lowered temperature on the micromechanical characteristics of metastable austenitic steel,” Phys. Met. Metallogr. 121 (10), 1015–1020 (2020).

N. B. Pugacheva, Yu. V. Nikolin, T. M. Bykova, and E. I. Senaeva, “Structure of Fe–Ni–Ti–C–B SHS composites,” Phys. Met. Metallogr. 123 (1), 1078–1084 (2022). https://doi.org/10.31857/S0015323022010107

M. M. Khrushchov and M. A. Babichev, Abrasion Wear (Nauka, Moscow, 1970) [in Russian].

Funding

This work was supported by the Russia Science Foundation, project no. 22-29-00188.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by N. Podymova

Rights and permissions

About this article

Cite this article

Pugacheva, N.B., Bykova, T.M. & Senaeva, E.I. The Structure and Fracture Pattern of a Сu–Ti–Al–Ni–Fe–C–B Composite after Abrasive Wear. Phys. Metals Metallogr. 123, 963–970 (2022). https://doi.org/10.1134/S0031918X22600920

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X22600920