Conclusions

-

1.

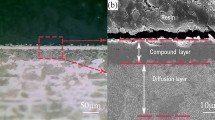

The titanium carbide layer formed by deposition of titanium on steel Kh12 was subjected to microprobe analysis.

-

2.

Thin coatings of titanium carbide (10–12 μ) on steel Kh12 with H 3300–3500 substantially improve the impact-abrasive wear resistance of this steel.

Similar content being viewed by others

Literature cited

V. N. Vinogradov, G. M. Sorokin, and G. M. Shreiber, “Method of testing impact-abrasive wear resistance,“ Zavod. Lab., No. 11, 1407 (1966).

Yu. A. Geller, L. P. Pavlova, and G. M. Sorokin, “Impact-abrasive wear of nitrided tool steels,“ Metalloved. Term. Obrab. Met., No. 1, 48 (1972).

Additional information

I. M. Gubkin Moscow Institute of Petrochemical and Gas Industry. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 10, pp. 64–65, October, 1976.

Rights and permissions

About this article

Cite this article

Sorokin, G.M., Minkevich, I.A. Effect of titanium coating on impact-abrasive wear of steel Kh12. Met Sci Heat Treat 18, 906–907 (1976). https://doi.org/10.1007/BF00705206

Issue Date:

DOI: https://doi.org/10.1007/BF00705206