Abstract

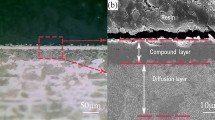

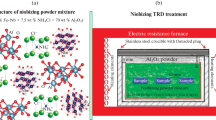

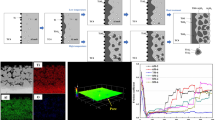

In the present study, the metallographic, mechanical and tribologic behaviors of AISI D2 steel specimens coated with TiC through the titanizing process were investigated. The titanizing treatment was performed at the temperatures of 900°C, 1000°C or 1100°C for 1 h, 2 h or 3 h using a solid-state box thermoreactive diffusion technique. In all cases, the predominant phase in the coating was TiC, but the mechanical properties of the coating varied with treatment condition. The wear resistance of the coated samples against a linear reciprocating Al2O3 ball improved as the hardness and thickness of the coating increased. The effective wear mechanism of samples that had been treated at 900°C, 1000°C and 1100°C were severe plastic deformation, delamination and polishing type wear, respectively. The wear performance was affected by coating layer’s thickness and uniformity as well as its surface hardness, elastic modulus and toughness.

Similar content being viewed by others

References

G. Schneider, Cutting Tool Application (Upper Saddle River: Prentice-Hall Publication, ASM International, 2002), pp. 2–65.

R.I. King, Handbook of High Speed Machining Technology (London: Springer, 1985), pp. 27–47.

H. Schulz and T. Moriwaki, CIRP Ann. (1996). https://doi.org/10.1016/S0007-8506(07)63250-8.

P. Koshya, R.C. Dewes, and D.K. Aspinwal, J. Mater. Proc. Tech. (2002). https://doi.org/10.1016/S0924-0136(02)00155-3.

G. Roberts, G. Krauss, and R. Kennedy, Tool Steels (Ohio: ASM International, 1980), pp. 493–553.

J.R. Davis, Surface Hardening of Steels: Understanding the Basics (Materials Park: ASM International, 2002), pp. 1–12.

F.E. Castillejo, D.M. Marulanda, J.J. Olaya, and J.E. Alfonso, Surf. Coat. Technol. (2014). https://doi.org/10.1016/j.surfcoat.2014.05.069.

F. Czerwinski, Thermochemical Treatment of Metals (InTech. Open https://doi.org/10.5772/51566, 2012), https://www.intechopen.com/books/heat-treatment-conventional-and-novel-applications/thermochemical-treatment-of-metals. Accessed 17 July 2018.

K.M. Winter, J. Kalucki, and D. Koshel, Imp. Mater. Perform. (2015). https://doi.org/10.1533/9780857096524.1.141.

J. Dossett and G.E. Totten, eds., ASM Handbook, Volume 4A, Steel Heat Treating Fundamentals and Processes (Ohio: ASM International, 2013), pp. 705–738.

P.V. Astakhov, Tribology of Metal Cutting (London: Elsevier, 2006), pp. 1–25.

G.T. Smith, Cutting Tool Technology: Industrial Handbook (Southampton: Springer, 2008), pp. 330–373.

T. Aria, Imp. Mater. Perform. (2015). https://doi.org/10.1533/9780857096524.5.703.

H. Pouraliakbara, G. Khalaj, L. Gomidželovic, M.J. Khalaj, and M. Nazerfakhari, Ceram. Int. (2015). https://doi.org/10.1016/j.ceramint.2015.03.306.

I. Hutchings and P. Shipway, Tribology Friction and Wear Engineering Materials (Amsterdam: Elsevier, 2017), pp. 260–272.

J.F. Shackelford and W. Alexander, Thermal Properties of Materials: Materials Science and Engineering Handbook, ed. J.F. Shackelford and W. Alexander (Boca Raton: CRC Press LLC, 2001), p. 157.

S. Sen, Vacuum (2005). https://doi.org/10.1016/j.vacuum.2005.01.009.

M. Biesuz and V.M. Sglavo, Surf. Coat. Technol. (2016). https://doi.org/10.1016/j.surfcoat.2015.12.063.

S. Taktak and S. Ulu, Ind. Lubr. Tribol. (2010). https://doi.org/10.1108/00368791011012452.

C.K.N. Oliveira, C.L. Benassi, and L.C. Casteletti, Surf. Coat. Technol. (2006). https://doi.org/10.1016/j.surfcoat.2006.03.036.

A. Günen, M.S. Karakaş, B. Kurt, and A. Çalık, Anti-Corros Methods Mater. (2014). https://doi.org/10.1108/ACMM-12-2012-1224.

A. Gunen, M. Ulutan, M.S. Gok, B. Kurt, and N. Orhan, J. Balk. Tribol. Assoc. 20, 362 (2014).

G. Krauss, Steels: Processing, Structure and Performance (Ohio: ASM International, 2015), pp. 335–369.

C. Barret and T.B. Massalski, Structure of Metals (Oxford: Pergamon, 1980), pp. 260–295.

B. Kurt, O. Sinoplu, C. Carboga, and B. Demirel, Pract. Metall. (2014). https://doi.org/10.3139/147.110235.

G.T. Bu, Y. Gao, and C.L. Wang, Mater. Sci. Forum (2012). https://doi.org/10.4028/www.scientific.net/MSF.704-705.1152.

Q. Xue, J. Li, P. Fan, R. Xin, and J. Zhang, Study on corrosion and wear resistance of titanizing coating on steel surface, (OnePetro publishing, 2015). https://www.onepetro.org/conference-paper/ISOPE-I-15-312. Accessed 17 June 2018.

M.S. Gök, Y. Küçük, A. Erdoğan, M. Öğe, E. Kanca, and A. Günen, Surf. Coat. Technol. (2017). https://doi.org/10.1016/j.surfcoat.2017.08.008.

D. Inman, A. Sodano, and J. Lloyd, Smart Mater. Struct. (2006). https://doi.org/10.1088/0964-1726/15/5/007.

F.H. Stott and M.P. Jordan, Wear (2001). https://doi.org/10.1016/S0043-1648(01)00601-9.

K. Kato, Tribol. Int. (1997). https://doi.org/10.1016/S0301-679X(96)00063-1.

N.M. Ismail, N.A. Amir-Khatif, M.A.K. Awang-Kecik, and M.A. Hanafiah-Shaharudin, Mater. Sci. Eng. (2016). https://doi.org/10.1088/1757-899X/114/1/012108.

U. Sen and S. Sen, Mater. Charact. (2003). https://doi.org/10.1016/S1044-5803(03)00104-9.

N. Outsuku and T. Muragami, Proceedings of Japan Society of Lubricants Engineering Annual Conference, October, 369–372, (1983).

J. Jiang, F.H. Stott, and M.M. Stack, Wear (1995). https://doi.org/10.1016/0043-1648(95)90004-7.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kurt, B., Günen, A., Kanca, Y. et al. Properties and Tribologic Behavior of Titanium Carbide Coatings on AISI D2 Steel Deposited by Thermoreactive Diffusion. JOM 70, 2650–2659 (2018). https://doi.org/10.1007/s11837-018-3108-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-3108-5