Conclusion

-

1.

A new precipitation-hardening spring alloy, 40NKKhTYuMD, has high ductility after quenching, which makes it possible to manufacture elastic elements of complex shape from it.

High strength and elastic characteristics are produced by quenching and aging.

-

2.

Alloy 40 NKKhTYuMD has high corrosion resistance in sulfuric acid of different concentrations at elevated temperatures and is classified as resistant.

-

3.

The alloy is hardened due to decomposition of the supersaturated solid solution with precipitation of finely dispersed phase of the Ni3(Ti, Al) type.

-

4.

Tests of parts made of alloy 40NKKhTYuMD showed that it can be used for elastic sensing elements in instruments.

Similar content being viewed by others

Literature cited

Yu. A. Bagaryatskii and Yu. D. Tyapkin, "X-ray analysis of aging in nickel-base alloys", in: Problems of Metal Science and Physics of Metals [in Russian], No. 5 (1958), p. 241.

N. A. Solov'eva and V. A. Sol'ts, "New nonmagnetic corrosion resistant alloy for springs", in: Precision Alloys [in Russian], No. 16 (1956), p. 289.

A. G. Rakhshtadt, Spring Steels and Alloys [in Russian], Metallurgiya, Moscow (1971), p. 256.

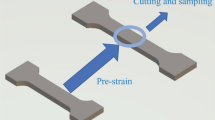

A. G. Rakhshtadt and M. A. Shtremel, "New method of determining the elastic limit on fiat samples", Zavod. Lab.,26, No. 6, 744 (1960).

Precision Alloys with Special Properties of Thermal Expansion and Elasticity [in Russian], Izd. Standartov, Moscow (1972).

B. G. Belov and D. G. Tufanov, "Effect of melting procedure on corrosion resistance of spring alloy 36NKhTYu", Metal. i Term. Obrabotka Metal., No. 10, 60 (1968).

A. P. Gulyaev et al., "Highly corrosion resistant alloy with high strength", Izv. Akad. Nauk SSSR, Metally, No. 5, 102 (1966).

M. Yu. Ustimenko et al., "Corrosion resistant alloy for elastic sensing elements", in: Special Steels and Alloys [in Russian], No. 1 (1972), p. 118.

E. A. Ul'yanin, "New corrosion resistant steels and alloys", Metal. i Term. Obrabotka Metal., No. 4, 14 (1974).

D. G. Tufanov, Corrosion Resistant Stainless Steels and Pure Metals [in Russian], Metallurgiya, Moscow (1973), p. 111.

B. G. Nazarov, E. F. Yakovleva, and G. P. Bogomolova, "Copper in heat resistant alloys", Metal. i Term. Obrabotka Metal., No. 5, 53 (1972).

Additional information

I. P. Bardin Central Scientific-Research Institute of Ferrous Metallurgy. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 9, pp. 43–47, September, 1975.

Rights and permissions

About this article

Cite this article

Sol'ts, V.A., Zhdanova, A.S. Corrosion resistant alloy 40NKKhTYuMD for elastic sensing elements in instruments. Met Sci Heat Treat 17, 771–775 (1975). https://doi.org/10.1007/BF00703065

Issue Date:

DOI: https://doi.org/10.1007/BF00703065