Conclusions

-

1.

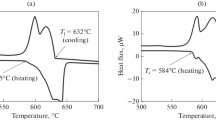

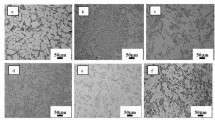

The basic hardening phase of casting Al-Mg-Zn alloys is the T-phase (Al2Mg3Zn3), which is segregated at temperatures from 160 to 170°C. On heating to 190°C and higher, the β-phase (Al3Mg2) begins to form — along the subgrain boundaries at first, and over the entire body of the grain at temperatures above 200°C.

-

2.

Coagulation of T-phase particles and growth of the β-phase lead to a reduction in the strength properties of an aluminum alloy containing 5.5% Mg and 2.5% Zn.

The best set of properties for this alloy corresponds to the T→β-phase transformation, which is observed after aging at 80°C for 8 h +190°C for 2 h. This aging regime is characterized by the homogenous segregation of highly disperse particles of the hardening phases T′ and T uniformly over the body of the grain.

Similar content being viewed by others

Literature cited

Dznong Legon, Krist. Technik,15, No. 6, 697–702 (1980).

Le Kong Zyong, Yu. A. Skakov, and E. V. Shelekhov, "Structural changes during aging of a casting aluminum alloy containing 3.5% Zn and 4% Mg," Izv. Akad. Nauk SSSR, Met., No. 3, 124–130 (1981).

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 3, pp. 56–57, March, 1985.

Rights and permissions

About this article

Cite this article

Parkhomenko, N.A., Gerchikova, N.S., Cherkasov, V.V. et al. Structure and properties of castings of the Al-Mg-Zn system. Met Sci Heat Treat 27, 233–236 (1985). https://doi.org/10.1007/BF00699661

Issue Date:

DOI: https://doi.org/10.1007/BF00699661