Abstract

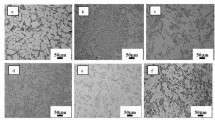

The microstructure and mechanical properties of new high-temperature casting aluminum alloys Al–5.6Cu–2.0Y–1Mg–0.8Mn–0.3Zr–0.15Ti–0.15Fe–0.15Si and Al–5.4Cu–3.0Er–1.1Mg–0.9Mn–0.3Zr–0.15Ti–0.15Fe–0.15Si are investigated. In an alloy with yttrium, modification with titanium gives rise to a decrease in the grain size from 190 to 40 μm, while the grain size in an alloy with erbium is 25 μm. Regarding the casting properties, the alloys are comparable to silumins alloyed with copper and magnesium. The greatest strengthening effect after quenching is achieved with aging at 210°C; the hardness is 130–133 HV. The tensile yield point at room temperature is 303–306 MPa with a relative elongation of 0.4%. At elevated temperatures of 200 and 250°C, the yield stress decreases to 246–250 and 209–215 MPa, and the elongation increases to 3 and 4–5.5%, respectively. The long-term strength retention after 100 h exposure to 250°C is 117–118 MPa. The presence of a solid solution that is sufficiently alloyed and strengthening dispersoids of the Al3(Zr,Er), Al3(Zr,Y), and Al20Cu2Mn3 phases and the Al8Cu4Y, (Al,Cu)11Y3, (Al,Cu,Y,Mn), Al8Cu4ErAl3Er, and (Al,Cu,Er,Mn) phases of crystallization origin in new alloys provide high levels of heat resistance.

Similar content being viewed by others

REFERENCES

GOST 1583–93. Casting Aluminum Alloys. Technical Conditions (IPK Izd-vo standartov, Minsk, 2000) [in Russian].

V. S. Zolotorevsky and N. A. Belov, Metal Science of Casting Aluminum Alloys (MISiS, Moscow, 2005).

V. S. Zolotorevsky, N. A. Belov, and M. V. Glazoff, Casting Aluminum Alloys (Alcoa Technical Center, Alcoa Center, 2007).

I. I. Novikov, Hot Brittleness of Nonferrous Metals and Alloys (Nauka, Moscow, 1966) [in Russian].

V. S. Zolotorevskiy and A. V. Pozdniakov, “Determining the hot cracking index of Al–Si–Cu–Mg casting alloys calculated using the effective solidification range,” Int. J. Cast Met. Res. 27, 193–198 (2014).

V. S. Zolotorevskiy, A. V. Pozdniakov, and A. Yu. Churyumov, “Search for promising compositions for developing new multiphase casting alloys based on Al–Cu–Mg matrix using thermodynamic calculations and mathematic simulation,” Phys. Met. Metallogr. 113, 1052–1060 (2012).

P. K. Shurkin, N. A. Belov, A. F. Musin, and A. A. Akse-nov, “ New high-strength casting aluminum alloy based on the Al–Zn–Mg–Ca–Fe system without requirement for heat treatment,” Izv. Vuzov. Tsvetn. Metall., No. 1, 48-58 (2020).

P. K. Shurkin, N. A. Belov, A. F. Musin, and M. E. Samokhina, “Effect of calcium and silicon on the character of solidification and strengthening of the Al–8% Zn–3% Mg alloy,” Phys. Met. Metallogr. 121, No. 2, 135–142 (2020).

N. A. Belov, A. V. Khvan, and A. N. Alabin, “Microstructure and phase composition of Al–Ce–Cu alloys in the Al-rich corner,” Mater. Sci. Forum 519–521(PART 1), 395–400 (2006).

N. A. Belov and A. V. Khvan, “The ternary Al–Ce–Cu phase diagram in the aluminum-rich corner,” Acta Mater. 55, 5473–5482 (2007).

A. V. Pozdniakov and R. Y. Barkov, “Microstructure and materials characterisation of the novel Al–Cu–Y alloy,” Mater. Sci. Technol. 34, No. 12, 1489–1496 (2018).

S. M. Amer, R. Yu. Barkov, O. A. Yakovtseva, and A. V. Pozdniakov, “Comparative analysis of structure and properties of quasi-binary Al–6.5Cu–2.3Y and Al–6Cu–4.05Er alloys,” Phys. Met. Metallogr. 121, 476–482 (2020).

A. V. Pozdnyakov, R. Y. Barkov, Z. Sarsenbaev, S. M. Amer, and A. S. Prosviryakov, “Evolution of microstructure and mechanical properties of a new Al–Cu–Er wrought alloy,” Phys. Met. Metallogr. 120, 614–619 (2019).

N. A. Belov, E. A. Belov, E. A. Naumova, T. A. Bazlova, and E. V. Alekseeva, “Structure, phase composition, and strengthening of cast Al–Ca–Mg–Sc alloys,” Phys. Met. Metallogr. 117, No. 2, 188–194 (2016).

A. V. Pozdnyakov, A. A. Osipenkova, D. A. Popov, S. V. Makhov, and V. I. Napalkov, “Effect of low additives of Y, Sm, Gd, Hf and Er on the structure and hardness of alloy Al–0.2% Zr–0.1% Sc,” Metalloved. Term. Obr. Met. 58, No. 9, 25–30 (2016).

A. V. Pozdnyakov, V. Yarasu, R. Yu. Barkov, O. A. Yakov-tseva, S. V. Makhov, and V. I. Napalkov, “Microstructure and mechanical properties of novel Al–Mg–Mn–Zr–Sc–Er alloy,” Mater. Lett. 202, 116–119 (2017).

H. L. Hao, D. R. Ni, Z. Zhang, D. Wang, B. L. Xiao, and Z. Y. Ma, “Microstructure and mechanical properties of Al–Mg–Er sheets jointed by friction stir welding,” Mater. Des. 52, 706–712 (2013).

R. Yu. Barkov, A. S. Prosviryakov, M. G. Khomutov, and A. V. Pozdnyakov, “Influence of Zr and Er contents on the structure and properties of Al–5Si–1.3Cu–0.5Mg alloy,” Phys. Met. Metallogr. (2021) (in press).

A. V. Pozdnyakov, R. Yu. Barkov, A. S. Prosviryakov, A. Yu. Churyumov, I. S. Golovin, and V. S. Zolotorevskiy, “Effect of Zr on the microstructure, recrystallization behavior, mechanical properties and electrical conductivity of the novel Al–Er–Y alloy,” J. Alloys Compd. 765, 1–6 (2018).

A. V. Pozdnyakov and R. Yu. Barkov, “Microstructure and mechanical properties of novel Al–Y–Sc alloys with high thermal stability and electrical conductivity,” J. Mater. Sci. Technol. 36, 1–6 (2020).

Y. Zhang, K. Gao, S. Wen, H. Huang, Z. Nie, and D. Zhou, “The study on the coarsening process and precipitation strengthening of Al3Er precipitate in Al–Er binary alloy,” J. Alloys Compd. 610, 27–34 (2014).

S. P. Wen, K. Y. Gao, Y. Li, H. Huang, and Z. R. Nie, “Synergetic effect of Er and Zr on the precipitation hardening of Al–Er–Zr alloy,” Scr. Mater. 65, 592–595 (2011).

S. P. Wen, K. Y. Gao, H. Huang, W. Wang, and Z. R. Nie, “Precipitation evolution in Al–Er–Zr alloys during aging at elevated temperature,” J. Alloys Compd. 574, 92–97 (2013).

Y. Zhang, H. Gao, Y. Kuai, Y. Han, J. Wang, B. Sun, S. Gu, and W. You, “Effects of Y additions on the precipitation and recrystallization of Al–Zr alloys,” Mater. Charact. 86, 1–8 (2013).

Y. Zhang, J. Gu, Y. Tian, H. Gao, J. Wang, and B. Sun, “Microstructural evolution and mechanical properties of Al–Zr and Al–Zr–Y alloys,” Mater. Sci. Eng., A 616, 132–140 (2014).

M. Song, K. Du, Z. Y. Huang, H. Huang, Z. R. Nie, and H. Q. Ye, “Deformation-induced dissolution and growth of precipitates in an Al–Mg–Er alloy during high-cycle fatigue,” Acta Mater. 81, 409–419 (2014).

S. P. Wen, W. Wang, W. H. Zhao, X. L. Wu, K. Y. Gao, H. Huang, and Z. R. Nie, “Precipitation hardening and recrystallization behavior of Al–Mg–Er–Zr alloys,” J. Alloys Compd. 687, 143–151 (2016).

R. Yu. Barkov, A. V. Pozdniakov, E. Tkachuk, and V. S. Zolotorevskiy, “Effect of Y on microstructure and mechanical properties of Al–Mg–Mn–Zr–Sc alloy with low Sc content,” Mater. Lett. 217, 135–138 (2018).

R. Yu. Barkov, A. G. Mochugovskii, M. G. Khomutov, and A. V. Pozdnyakov, “Effect of Zr and Er small additives on the phase composition and mechanical properties of Al–5Si–1.3Cu–0.5Mg alloy,” Phys. Met. Metallogr. 122, No. 2, 161–168 (2021).

M. Li, H. Wang, Z. Wei, and Z. Zhu, “The effect of Y on the hot-tearing resistance of Al–5 wt % Cu based alloy,” Mater. Des. 31, 2483–2487 (2010).

L. Zhang, P. J. Masset, F. Cao, F. Meng, L. Liu, and Z. Jin, “Phase relationships in the Al-rich region of the Al–Cu–Er system,” J. Alloys Compd. 509, 3822–3831 (2011).

A. V. Pozdnyakov, R. Yu. Barkov, S. M. Amer, V. S. Levchenko, A. D. Kotov, and A. V. Mikhaylovskaya, “Microstructure, mechanical properties and superplasticity of the Al–Cu–Y–Zr alloy,” Mater. Sci. Eng., A 758, 28–35 (2019).

S. M. Amer, R. Yu. Barkov, O. A. Yakovtseva, I. S. Loginova, and A. V. Pozdniakov, “Effect of Zr on microstructure and mechanical properties of the Al–Cu–Er alloy,” Mater. Sci. Technol. 36, No. 4, 453–459 (2020).

S. M. Amer, O. A. Yakovtseva, I. S. Loginova, S. V. Medvedeva, A. S. Prosviryakov, A. I. Bazlov, R. Yu. Barkov, and A. V. Pozdniakov, “The phase composition and mechanical properties of the novel precipitation-strengthening Al–Cu–Er–Mn–Zr alloy,” Appl. Sci. 10, No. 15, 5345–5353 (2020).

S. M. Amer, R. Yu. Barkov, and A. V. Pozdniakov, “Effect of Mn on the phase composition and properties of Al–Cu–Y–Zr alloy,” Phys. Met. Metallogr. 121, No. 12, 1227–1232 (2020).

S. M. Amer, R. Yu. Barkov, and A. V. Pozdniakov, “Comparative analysis of structure and properties of quasibinary Al–6.5Cu–2.3Y and Al–6Cu–4.05Er alloys,” Phys. Met. Metallogr. 121, No. 5, 476–482 (2020).

S. M. Amer, R. Yu. Barkov, and A. V. Pozdniakov, “Effect of iron and silicon impurities on phase composition and mechanical properties of Al–6.3Cu–3.2Y alloy,” Phys. Met. Metallogr. 121, No. 10, 1002–1007 (2020).

GOST 4784-2019. Aluminum and Wrought Aluminum Alloys. Brands (IPK Izd-vo Standartov, Moscow, 2019).

ASM HANDBOOK. Properties and Selection: Nonferrous Alloys and Special-Purpose Materials (The Materials Information Company, 2010), Vol. 2.

A. Lotfy, A. V. Pozdniakov, V. S. Zolotorevskiy, E. Mohamed, M. T. Abou El-Khair, A. Daoud, and F. Fairouz, “Microstructure, compression and creep properties of Al–5% Cu–0.8Mn/5% B4C composites,” Mater. Res. Exp. 6, 095530 (2019).

Funding

This study was supported by the Russian Science Foundation (project no. 19-79-10242). S.M. Amer is funded by a partial scholarship from the Ministry of Higher Education of the Arab Republic of Egypt.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Kadkin

Rights and permissions

About this article

Cite this article

Amer, S.M., Barkov, R.Y., Prosviryakov, A.S. et al. Structure and Properties of New Heat-Resistant Cast Alloys Based on the Al–Cu–Y and Al–Cu–Er Systems. Phys. Metals Metallogr. 122, 908–914 (2021). https://doi.org/10.1134/S0031918X21090027

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X21090027