Conclusions

-

1.

A successive unconditional minimization algorithm using penalty functions without calculation of derivatives is an efficient approach to the computerized optimization of structural elements of hybrid composites with regard to cost and weight, given a small number of design variables and uncomplicated calculation of the objective function and limitations.

-

2.

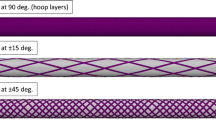

A program was developed for computer optimization, by the method of penalty functions, of a hybrid composite shaft according to cost and weight in the case where the shaft is obtained by winding, is made of two dissimilar fiber composites, and is subject to limitations on the strength of the single layers, stability in torsion, and critical velocity and designprocessing limitations.

-

3.

The examples presented of the optimization of carbon-plastic Cardan shafts shows that the most important material characteristics affecting the optimum design are the moduli of normal elasticity in the fiber direction, the shear strength of the single layers, and the density and cost of the materials. Given a low critical velocity in a cost and weight optimization of composite Cardan shafts for trucks, a substantial cost reduction can be realized with a slight increase in weight compared to the optimum weight. The optimum design of a hybrid composite Cardan shaft for an automobile, with a high critical velocity, depends only slightlyon the relationship between cost and weight in the objective function. In this case, a thick carbon-plastic is required to give the shaft high bending stiffness.

Similar content being viewed by others

Literature Cited

G. S. Kats and D. V. Milevski, Fillers for Polymer Composites (Handbook) [in Russian], Moscow (1981).

V. A. Chase, “Automotive applications of composite materials,” in: 11th Nat. SAMPE Techn. Conf., Boston, MA., Vol. 11, 388–398 (1979).

J. H. Cassis and L. A. Schmitt, “On the implementation of the extended interior penalty function,” Int. J. Numerical Methods Eng.,10, 3–23 (1976).

M. J. D. Powell, “An efficient method for finding the minimum of a function of several variables without calculating derivatives,” Comput. J.,7, No. 2, 155–162 (1964).

N. N. Moiseev, Yu. P. Ivanilov, and E. M. Stolyarova, Methods of Optimization [in Russian], Moscow (1978).

A. Fiacco and G. McCormick, Nonlinear Programming. Methods of Successive Unconditional Minimization [Russian translation], Moscow (1972).

C. Ruegg, “Carbon and aramid reinforced plastic in the manufacture of automotive propeller shafts,” in: CIBA-GEIGY, Basel (1982).

Yu. N. Rabotnov and A. N. Polilov, “Strength criteria for fiber-reinforced plastics,” in: Fracture, Vol. 3, ICF4, Canada, June 19–24, 1977, pp. 1059–1065.

R. I. Nepershin, K. A. Shishkin, G. V. Romanova, S. I. Petrov, and V. G. Pilos'yan, “Algorithm for computer calculation of the technical cohesive strength of multilayered composites in the absence and presence of stress concentration,” Mekh. Kompozitn. Mater., No. 1, 48–52 (1981).

Yu. N. Rabotnov, Mechanics of Deformable Solids [in Russian], Moscow (1979).

“Analysis and design of structures,” in: Composite Materials [in Russian], Vol. 7, Moscow (1978).

Author information

Authors and Affiliations

Additional information

Translated from Mekhanika Kompozitnykh Materialov, No. 4, pp. 690–695, July–August, 1986.

Rights and permissions

About this article

Cite this article

Nepershin, R.I., Klimenov, V.V. Optimum computer design of a composite cardan shaft according to the criteria of cost and weight. Mech Compos Mater 22, 490–494 (1987). https://doi.org/10.1007/BF00692262

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00692262