Conclusions

-

1.

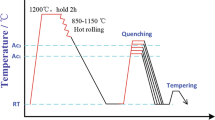

High-temperature brittleness due to slow cooling in the range of 800–1000°C is caused by the precipitation of titanium carbides in the boundaries of austenite grains.

-

2.

Rapid cooling from the hot deformation temperature or the completion of deformation at a temperature not over 800–850° prevents high-temperature brittleness.

-

3.

The hot rolled steel has the optimal combination of properties after hardening. Additional heating for quenching may lower the strength (the effect of HTTMT is eliminated) and the toughness (χ phase is precipitated).

-

4.

The quantity of intermetallic compounds in anodic residues (χ phases, Fe2Mo and ε-Fe3Mo2) after holding at 700–900° for 1 h may reach 2.5%; the type of intermetallic compounds and the quantitative ratio evidently depend on the temperature of the preceding treatment and the quenching temperature. With quenching from 950° and higher the phase composition is qualitatively and quantitatively similar to that of the hot worked steel.

-

5.

In cases where the hot worked must be reheated the optimal quenching temperature is 950–1000° with holding for 1 h or more, followed by rapid cooling.

Similar content being viewed by others

Literature cited

H. Back and D. Kalish, Met. Trans.,3, 4, 1012 (1972).

D. Kalish and H. Rack, Met. Trans.,2, 9, 2665 (1971).

G. Spaeder, R. Brown, and W. Murphy, TASM,60, 3, 418 (1967).

O. K. Revyakina et al., "Heat treatment of large extrusions and bars of steel 00N18K9M5T," Metal. i Term. Obrabotka Metal., 4, 18 (1971).

ASTM Publication PDTS-19i, York, Pennsylvania (1969).

E. Thompson and D. West, JISI,210, 9, 691 (1972).

V. B. Spiridonov et al., "Structural changes during aging of maraging steel 03Kh11N10M2T," Metal. i Term. Obrabotka Metal., 10, 28 (1974).

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 7, pp. 42–47, July, 1975.

Rights and permissions

About this article

Cite this article

Spiridonov, V.B., Fridman, V.S. Eigh-temperature brittleness and selection of quenching temperature for stainless maraging steels. Met Sci Heat Treat 17, 589–594 (1975). https://doi.org/10.1007/BF00680407

Issue Date:

DOI: https://doi.org/10.1007/BF00680407