Conclusions

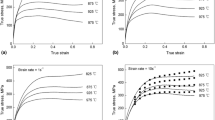

Double heat treatment consisting of quenching from 1050–1080°C in air and tempering for 16 h in air at 750°C provides the highest resistance to relaxation in the KhN77TYu alloy.

Similar content being viewed by others

Literature cited

F. F. Khimushin, Alloying, Heat Treatment and Properties of Heat Resistant Steels and Alloys [in Russian], Oborongiz (1962).

S. B. Maslenkov and G. V. Éstulin, “FMM” (1962), No. 6.

V. Betteridge, Heat Resistant Alloys of the Nimonik Type [Russian translation], Moscow, Metallurgizdat (1961).

Additional information

Central Scientific Research Institute of Ferrous Metallurgy Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1, pp. 60–63, January, 1966

Rights and permissions

About this article

Cite this article

Borzdyka, A.M., Astakhova, L.M. & Salakhova, L.I. Effect of heat treatment on the relaxation resistance of the KhN77TYu alloy. Met Sci Heat Treat 8, 65–67 (1966). https://doi.org/10.1007/BF00660168

Issue Date:

DOI: https://doi.org/10.1007/BF00660168