Conclusions

-

1.

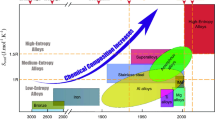

Deformation of two-phase alloys under superplasticity conditions of different types substantially improves the mechanical properties.

-

2.

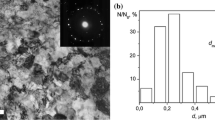

The improvement in the strength and plasticity of two-phase alloys is due to the characteristics of the formation of the fine structure under superplasticity conditions. This includes the development of interphase surface, the high dislocation density and concentration of vacancies, the small size of substructural elements, and negligible second-order internal stresses.

-

3.

The structural characteristics of superplastic aggregates cause ductile fracture and increase the work of crack propagation.

-

4.

The main reasons for the supersaturation of superplastic aggregates with lattice defects are the highly developed interphase surface, the volume effect of transformations (degree of supersaturation of polycrystals with dislocations and point defects proportional to ΔV/V), and the high hydrostatic pressure during extrusion and rolling.

-

5.

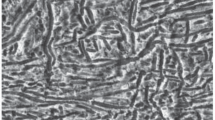

The multicomponent texture of two-phase alloys based on titanium and iron formed under superplasticity conditions indicates the effective development of multiple slip processes occurring under facilitated conditions. The latter is one reason for the reduction of the resistance to deformation in super-plasticity and the high sensitivity of the flow stress to changes in deformation rate.

Similar content being viewed by others

Literature cited

A. A. Bochvar and Z. A. Sviderskaya, "Phenomenon of superplasticity in alloys of zinc with aluminum," Izv. Akad. Nauk SSSR, OTN, No. 9, 84 (1945).

A. P. Gulyaev and L. M. Sarmanova, "Technological plasticity of high-speed steels,", Metal. i Term. Obrabotka Metal., No. 7, 2–12 (1969).

Ya. M. Okhrimenko, V. I. Zalesskii, and O. M. Smirnov, "Temperature-rate conditions of deformation of steel ShKh15 in the period of polymorphous transformation," Izv. Vuzov, Chernaya Metallurgiya, No. 5 (1965).

M. De Jong and G. W. Rathenau, Acta Met.,9, No. 8, 714–720 (1961).

R. Kot and V. Weiss, Metal Trans.,1, No. 10, 2885–2693 (1970).

M. Kh. Shorshorov, A. S. Tikhonov, and G. N. Kofanova, "Strengthening titanium alloys during treatment under superplastic conditions," Fiz. i Khim. Obrabotki Mat., No. 6, 89–94 (1972).

K. P. Gurov et al., Fiz. Metal. Metalloved.,34, No. 6, 1145–1119 (1972).

A. S. Tikhonov et al., "Theory of superplasticity in martensitic transformations," Fiz. Metal. Metalloved.,36, 2, 237–240 (1973).

R. H. Johnson, Metals and Materials,4, No. 9, 115–134 (1970).

Additional information

A. A. Baikov Institute of Metallurgy. Kuibyshev Aviation Institute. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 8, pp. 9–13, August, 1974.

Rights and permissions

About this article

Cite this article

Tikhonov, A.S., Prokhorova, I.I., Gaponov, Y.N. et al. Structural characteristics and mechanical properties of superplastic two-phase alloys. Met Sci Heat Treat 16, 647–651 (1974). https://doi.org/10.1007/BF00658428

Issue Date:

DOI: https://doi.org/10.1007/BF00658428