Conclusions

-

1.

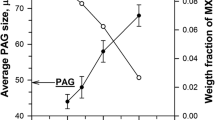

Carbide-forming alloying elements increase the rate of hardening of high-manganese steel.

-

2.

The effect of individual alloying elements is associated with the nucleation and movement of dislocations, which depends on the amount and dispersity of intermetallic compounds formed in the steel that induce hardening.

Similar content being viewed by others

Literature cited

Yu. A. Shul'te and M. I. Kurbatov, in: Physicochemical Basis of Steel Production [in Russian], Metallurgizdat, Moscow (1961).

Yu. A. Shul'te, Nonmetallic Inclusions in Electric Steel [in Russian], Metallurgiya, Moscow (1964).

M. V. Karakula and L. I. Parfenov, Liteinoe Proizvodstvo, No. 7 (1966).

Yu. D. Novomeiskii and V. M. Gladkov, High-Manganese Austenitic Steel G13L [in Russian], Metallurgiya, Moscow (1969).

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1, pp. 61–62, January, 1972.

Rights and permissions

About this article

Cite this article

Parfenov, L.I., Sorokin, G.A. & Matyuk, A.É. Effect of modifiers on hardening of steel 110G13L during strain hardening. Met Sci Heat Treat 14, 66–67 (1972). https://doi.org/10.1007/BF00658354

Issue Date:

DOI: https://doi.org/10.1007/BF00658354