Conclusions

-

1.

It was confirmed that nickel lowers the cold brittleness threshold of improved steels (with 0.2 and 0.4% C).

-

2.

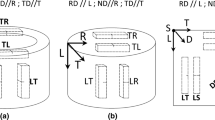

The cold brittleness threshold, determined from the proportion of the ductile component in the fractures, does not depend on the direction of the grain in the sample or the sharpness of the notch.

-

3.

Nickel (up to 3–4%) increases the work of development of the crack under conditions of ductile fracture and reduces the work of nucleation somewhat.

-

4.

The variation of the impact strength with the notch root radius at different temperatures shows that the beginning of the transition to the brittle state is accompanied by a reduction of the work of development while throughout the range of the transition to the brittle state the value of the work of nucleation remains constant, beginning to decrease only when adev=0, i.e., at the temperature of the lower limit of the cold brittleness threshold.

-

5.

The electron microscopic investigation of the fractures showed; a) Cupped fracture above the cold brittleness threshold (adev, anuc≫0); b) sections of cupped (ductile) and riverine (brittle) fracture within the cold brittleness range (anuc>0, adev→0); c) riverine fracture at the temperature corresponding to the lower limit of the cold brittleness threshold (anuc>0, adev=0); d) at temperatures below the lower limit of the cold brittleness threshold (anuc→0, adev=0) fractures are characterized by the absence of plastic deformation and by transcrystalline shearing with tongues.

-

6.

With increasing nickel concentrations the size of the facets in ductile fractures decreases, which apparently is responsible for the increase in the work of development of the crack.

Similar content being viewed by others

Literature cited

A. P. Gulyaev, MiTOM, No. 5, 7 (1961).

M. M. Shteinberg, Stal' (1949).

V. D. Sadovskii and N. P. Chuprakova, Transactions of the Institute of Metal Physics and Metallurgy [in Russian], Izd. AN SSSR (1946).

A. P. Gulyaev, O. N. Meshcherinova, and T. N. Trifonova, In: Special Steels and Alloys [in Russian], No. 2, Metallurgizdat, Moscow (1962).

W. Rees, B. Hopkins, and H. Tepler, J. Iron and Steel Institute,177 (1954).

A. P. Gulyaev, MiTOM, No. 12 (1962).

O. N. Meshcherinova, MiTOM, No. 12 (1962).

Ya. E. Gol'dshtein and G. A. Charushnikova, MiTOM, No. 12 (1962).

O. N. Meshcherinova et al., Zhurnal Minskogo Sovnarkhoza, No. 12 (1958).

A. P. Gulyaev and E. K. Novikova, In: Special Steels and Alloys [in Russian], No. 39, Metallurgizdat, Moscow (1965).

M. N. Georgiev and A. P. Gulyaev, Stal', No. 2 (1967).

A. P. Gulyaev and V. N. Nikitin, Zavodskaya Laboratoriya, No. 7 (1964).

A. P. Gulyaev, Zavodskaya Laboratoriya, No. 4 (1967).

Additional information

TsNIIChERMET. Translated from Metallovedenie i Termicheskaya Obraboka Metallov, No. 9, pp. 46–52, September, 1967.

Rights and permissions

About this article

Cite this article

Novikova, E.K., Gulyaev, A.P. & Meshcherinova, O.N. Influence of nickel on the ductility of structural steel. Met Sci Heat Treat 9, 687–692 (1967). https://doi.org/10.1007/BF00649054

Issue Date:

DOI: https://doi.org/10.1007/BF00649054