Abstract

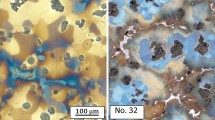

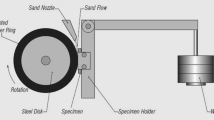

The objective of this work stems from the environmentally assisted embrittlement suffered by austempered ductile iron (ADI) when its surface is submerged in water. This phenomenon leads to a drop in elongation and ultimate tensile strength of about 75% and 10%, respectively, while the 0.2% offset strain stress remains unaffected. Heat-treating a high Si steel, an ausferritic matrix similar to that present in the ADI under study is obtained, yielding giving a very good combination of tensile strength and elongation. In this manner, it was possible to examine the influence of the metallic matrix such as that present in ADI, though without nodules and cell boundaries, also called last to freeze zones (LTF). Tensile test evaluations on ADI and steel samples under dry and wet conditions were carried out. Additionally, a very specific test, introducing surface cracks, was conducted with the purpose of expanding the current knowledge on this particular kind of fracture. Earlier investigations on ADI have suggested that the process of embrittlement starts in a surface crack generated at the early stages of plastic deformation in LTF zones, which results from the solidification process, where pores, inclusions and unreacted austenite are present. In this manner, water penetrates and weakens the material strength, making the crack grow very fast and leading to an instantaneous samples failure. The main results obtained in this work include the confirmation of the deleterious effect of the LTF zones in the embrittlement process and the fracture surface analysis showing characteristic features of this kind of failure.

Similar content being viewed by others

References

R.A. Martínez, A. Cassanelli, H. Mejías, J.C. González, B.M. Patchett, and L.A. De Vedia, Development of an AWS E90T1-B3 Type Flux Cored Electrode for Welding 2.25% Cr—1 Mo Steel, Trends Weld. Res., 1989, 1, p 575

G.P. Tiwari, A. Bose, J.K. Chakravartty, S.L. Wadekar, M.K. Totlani, R.N. Arya, and Fotedar, A Study of Internal Hydrogen Embrittlement of Steels, Mater. Sci. Eng. A, 2000, A286, p 269

R.A. Siddiqui and H.A. Abdullah, Hydrogen Embrittlement in 6063 Aluminum Alloy, J. Mater. Process. Technol., 2005, 170, p 430

K. Ina and H. Koizumi, Penetration of Liquid metals into Solid Metals and Liquid Metal Embrittlement, Mater. Sci. Eng. A, 2004, 387, p 390

R.E. Clegg and D.R.H. Jones, Liquid Metal Embrittlement of Tensile Specimens of En19 Steel by Tin, Eng. Fail. Anal., 2003, 10, p 119

T. Auger and G. Lorang, Liquid Metal Embrittlement Susceptibility of T91 Steel by Lead–Bismuth, Scr. Mater., 2005, 52, p 1323

E. Izumoto and R. Nishimura, Failure analysis of a Weld-Decayed Austenitic Stainless Steel, Corros. Sci., 2011, 53, p 886

X. Gong, P. Marmy, L. Qin, B. Verlinden, M. Wevers, and M. Seefeldt, Effect of Liquid Metal Embrittlement on Low Cycle Fatigue Properties and Fatigue Crack Propagation Behavior of a Modified 9Cr–1Mo ferritic–Martensitic Steel in an Oxygen-Controlled Lead–Bismuth Eutectic Environment at 350°C, Mater. Sci. Eng. A, 2014, 618, p 406

S. Komatsu, C.Q. Zhou, S. Shibutani, and Y. Tanaka, Embrittlement Characteristics of Fracture Toughness in Ductile Iron by Contact with Water, Int. J. Cast Metals Res., 1999, 11, p 539

R.A. Martínez, R. Boeri, and J.A. Sikora, Embrittlement of Austempered Ductile Iron Caused by Contact with Water and Other liquids, Int. J. Cast Met. Res., 2000, 13, p 9

B. Laine, S.N. Simison , R.A. Martínez, R. Boeri, Anales del congreso CONAMET/SAM—SIMPOSIO MATERIA., Santiago de Chile, Chile, 2002, (1), p. 121

G. Rivera, R. Boeri, and J. Sikora, Revealing the Solidification Structure of Nodular Iron, Int. J. Cast Met. Res., 1995, 8(1), p 1–5

H.K.D.H. Bhadeshia, Bainite in Steels, 2nd ed., IOM Communications Ltd, London, 2001

J.L. Páez, F. Fuentes, and A. Battagliese, Tratamiento isotérmico de los aceros aleados al silicio Tipo SAE 92XX, Rev. Metal. Madrid., 1996, 32, p 3

N. Tsuji, M. Ayada, T. Takashima, and Y. Saito, Ausformed Bainite in SUP7 Spring Steel, Tetsutihagane, 1999, 85, p 419

S.K. Putatunda, A.V. Singar, R. Tackett, and G. Lawes, Development of a High Strength High Toughness Ausferritic Steel, Mater. Sci. Eng. A, 2009, 513–514, p 329–339

R.A. Martínez, S. Simison, R. Boeri, Crack Initiation in Austempered Ductile iron Strained in Contact with Different Liquids, Science and Processing of Cast Iron, 2006, vol 1. p 145–150

L. Masud, R.A. Martínez, S. Simison, and R. Boeri, Embrittlement of Austempered Ductile Iron on Contact with Water—Testing Under Applied Potential, J. Mater. Sci., 2003, 38, p 2971

L. Caballero, M. Elices, and R.N. Parkins, Environment-Sensitive Fracture of Austempered Ductile Iron, Corrosion, 2005, 61, p 51

D. Rajnovic, S. Balos, L. Sidjanin, O.E. Cekic, and J.G. Novakovic, Tensile Properties of ADI, Material in Water and Gaseous Environments, Mater. Charact., 2015, 101, p 26

R.A. Martinez, Fracture Surfaces and the Associated Failure Mechanisms in Ductile Iron with Different Matrices and Load Bearing, Eng. Fract. Mech., 2010, 77, p 2749

G.L. Greno, J.L. Otegui, and R. Boeri, Mechanism of Fatigue Crack Growth in Austempered Ductile Iron, Int. J Fatigue, 1999, 21, p 35

S. Lynch, Ductile and Brittle Crack Growth: Fractography, Mechanisms and Criteria, Mater. Forum, 1988, 11, p 268

Acknowledgments

This work could be the platform for the study of this and other steels, when the load bearing is, for example, of cyclic nature in order to evaluate nucleation and cracks propagation in the presence of water. In addition, the study could be extended to other metallic alloys.

Funding

This study was funded by the National Scientific and Technical Research Council (CONICET)—Grant PIP 0047. The author declares that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Martinez, R.A. Evaluation of the Role of Metallic Matrix on Environmentally Assisted Embrittlement of Austempered Ductile Iron (ADI) Using High Si Steel. J. of Materi Eng and Perform 27, 6597–6605 (2018). https://doi.org/10.1007/s11665-018-3725-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3725-8