Abstract

A study has been made of the stress-strain characteristics of high-impact composites based on poly sty renes (PS) or polycarbonates (PC) in uniaxial stretching at temperatures close to the glass transition temperature of the matrix material Heterogeneity of the structure of the material at the microlevel, owing to the presence of a graft copolymer in the PS composites or the presence of polyethylene terephthalate (a reactive additive) in the PC, tends to lower the effective glass transition temperature as determined at high elongations. Weak interaction of the impact-strength modifiers with the matrix material (determining the heterogeneity of the structure at the macrolevel) results in a lower stability of uniform stretching in the region of the high-elastic state, but increases the values of the elongation at break in the transition region from the glassy state to the high-elastic state. From the standpoint of achieving high strength and deformability of high-impact composites during their processing, the structure should be organized so as to provide optimal heterogeneity at both the microlevel and macrolevel.

Similar content being viewed by others

References

A. Ya. Malkin, S. A. Vol'fson, V. N. Kuleznev, and G. I. Faidel', Polystyrene [in Russian], Moscow (1975).

T. N. Andreeva, A. S. Kolerov, T. N. Vakhtinskaya, I. I. Solov'eva, and T. N. Yudakova, “High-impact materials based on polycarbonate,” Plast. Massy, No. 2, 24–27 (1993).

G. D. Ballova, T. A. Stepanova, and A. D. Chegodaeva, “Production of high-impact styrene copolymers by the block-suspension method, ” Obz. Inf. Nauchno-Issled. Inst. Tekh.-Ekon. Issled. Minist. Khim. Promst. SSSR, Moscow (1977).

J. W. Barlow and D. R. Paul, “Mechanical compatibilization of immiscible blends,” Polym. Eng. Sci.,24, No. 8, 525–533 (1984).

M. Xantos and S. S. Dagli, “Compatibilization of polymer blends by reactive processing,” Polym. Eng. Sci.,31, No. 13, 929–935 (1991).

D. M. Bigg, “Mechanical properties of particulate filled polymer,” Polym. Compos.,8, No. 2, 115–122 (1987).

R. J. Farris, “The influence of vacuole formation on the response and failure of filled elastomers,” Trans. Soc. Rheol.,12, No. 2, 315–324 (1968).

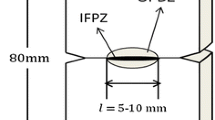

Ya. Ya. Indulevich, L. A. Irgen, G. M. Kerch, D. É. Pablak, and M. G. Tsiprin, “Automated system for determining Theological properties of polymer solutions and melts,” Mekh. Kompoz. Mater., No. 1, 109–113 (1985).

V. E. Dreval and E. K. Borisenkova, “Peculiarities of rheological behavior of filled polymer melts in uniaxial stretching,” Rheol. Acta,32, No. 4, 337–351 (1993).

B. I. Shapiro, Yu. V. Nikitin, V. L. Budtov, N. G. Podosenova, V. M. Belyaev, V. A. Zinchenko, L. L. Sul'zhenko, and A. F. Nikolaev, “Influence of properties of polystyrene matrix on characteristics of high-impact polystyrene,” Plast. Massy, No. 2, 43–44 (1977).

I. I. Perepechko and V. V. Nizhegorodov, “Relaxation processes in block copolymers of butadiene rubber and polystyrene,” in: Mechanical Properties of Rubbers and Rubber/Cord Composites: Test Methods (Proceedings of International Conference IRC-94), Moscow (1994), Vol. 4, pp. 483–489.

I. M. Ward, Mechanical Properties of Solid Polymers, Wiley, New York (1971).

M. G. Tsiprin and L. A. Irgen, “Stability of longitudinal flow and stretchability of polymer melts,” Mekh. Kompoz. Mater., No. 1, 105–114 (1992).

V. A. Danilov. I. I. Perepechko, V. V. Nizhegorodov, Yu. A. Godovskii, E. V. Konyukhov, and S. I. Belousov, “Component compatibility and relaxation processes in mixtures of polycarbonate and polybutylene terephthalate,” Vysokomol. Soedin. A,36, No. 1, 69–74 (1994).

I. I. Perepechko, V. A. Danilov, V. V. Nizhegorodov, N. P. Bessonova, and E. V. Konyukhova, “Viscoelastic behavior and relaxation processes in mixtures of polycarbonate and polybutylene terephthalate,” Vysokomol. Soedin. A,35, No. 2, 174–178 (1993).

Author information

Authors and Affiliations

Additional information

Translated from Mekhanika Kompozitnykh Materialov, Vol. 31, No. 4, pp. 509–517, July–August, 1995.

Rights and permissions

About this article

Cite this article

Tsiprin, M.G., Irgen (Jirgens), L.A. Characteristics of stretching of high-impact polystyrene and polycarbonate close to the glass transition temperature. Mech Compos Mater 31, 371–376 (1996). https://doi.org/10.1007/BF00632626

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00632626