Abstract

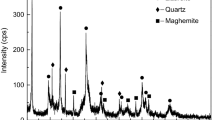

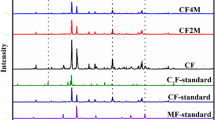

Dense, polycrystalline CoFe2O4, CoAl0.02Fe1.98O4, and CoAl0.1Fe1.9O4 were reduced in flowing H2/0.01% H2O at temperatures between 500 and 800° C. The reactions proceeded in a topochemical fashion. The rate of advance of the reaction interface was determined by direct measurement and by thermogravimetric analysis. An anomalous decrease in the reduction kinetics was observed for CoFe2O4 around 650° C and for CoAl0.02Fe1.98O4 at 750° C. This reaction rate anomaly could be attributed to the appearance of a wüstite-type subscale. The effect of the substitutional Al3+ ions was to decrease the interfacial reaction rates. In the lower temperature range, the reaction was dominated by the interface reaction. With increasing temperatures, the importance of the gas transport resistance through the porous metal product scale increased. The microstructure of the scales was examined extensively. Pronounced grain-boundary attack was observed at lower temperatures leading to the formation of a distributed reaction interface. At higher temperatures, the reaction interface was better defined. The pore structure of the scales was examined after polishing and sputter etching. While changes in the pore morphology were observed, they were not correlated with the anomalous reaction rate effects.

Similar content being viewed by others

References

R. H. Spitzer, F. S. Manning andW. O. Philbrook,Trans. Met. Soc. AIME 236 (1966) 726.

E. T. Turkdogan andJ. V. Vinters,Met. Trans. 2 (1971) 3175.

J. E. EdstrÖM,J. Iron Steel Inst 175 (1953) 289.

M. C. Udy andC. H. Lorig,Trans. Met. Soc. AIME 154 (1943) 162.

J. Henderson,J. Austr. Inst. Met. 7 (1962) 115.

J. Szekely andJ. W. Evans,Chem. Eng. Sci. 26 (1971) 1901.

K. R. Lilius,Acta Polytec. Scand 118 (1974) 6.

B. Delmon, ″Reactivity of Solids″, Vol. 7 (Chapman and Hill, London, 1972) pp. 567–75.

E. Aukrust andA. Muan,Trans. Met. Soc. AIME 230 (1964) 1395.

N. I. Il'chenko andV. A. Yuza,Kin. Katal 2 (1966) 118.

W. Verhoeven andB. Delmon,Compt. Rend. Aca. Sci. Paris 262C (1966) 33.

W. Machu andS. Y. Ezz,Arch. Eisenhuttenw. 28 (1957) 367.

D. K. Lambiev, T. M. Atanassov andO. B. Stoimenov,Dokl. Bulg. Akad. Nauk 27 (1979) 1675.

M. H. Tikkanen, B. O. Rosell andO. Wiberg,Acta Chem. Scand. 17 (Ab3) 513.

E. Aukrust andA. Muan,Trans. Met. Soc. AIME 230 (1964) 1378.

Y. Lida andK. Shimada,Bull. Chem. Soc. Japan 33 (1960) 8.

W. M. McKewan,Trans. Met. Soc. AIME 218 (1960) 2.

J. Porter andL. C. De Jonghe, Lawrence Berkeley Laboratory Report LBL-9801, June (1979)Met. Trans. B (1980).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ray, M.C., De Jonghe, L.C. Reduction kinetics and microstructures of Al3+-containing cobalt ferrites. J Mater Sci 15, 2241–2252 (1980). https://doi.org/10.1007/BF00552313

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00552313