Abstract

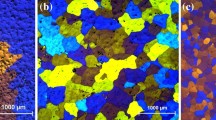

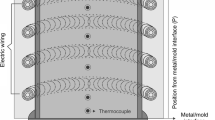

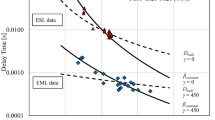

A major challenge to solidification theory over nearly three decades has been the understanding, prediction and control of rapidly solidified microstructures. The present paper reports results of systematic and controlled conditions of rapid solidification in Al-Mn alloys, which involved measurement of undercooling, solute concentration and cell spacing for solidification front velocities, which were increased progressively, to the level needed for partitionless solidification into a microsegregation-free solid which, in principle, can be crystalline, quasicrystalline or amorphous. Comparison of the measurements with predictions of theoretical modelling give an encouraging level of agreement.

Similar content being viewed by others

Abbreviations

- A :

-

constant = π2τ/P2D2

- A′ :

-

constant = k(ab)1/2

- B :

-

constant = mC0pξc/D[1−pIv(P)]

- B′ :

-

constant

- C :

-

G(Km−1)

- C EU :

-

eutectic composition (at %, wt %)

- C 0 :

-

alloy concentration (at %, wt %)

- C *L :

-

tip concentration in liquid (at %, wt.%)

- C *S :

-

tip concentration in solid (at %, wt %)

- D :

-

diffusion coefficient in liquid (m2s−1)

- G :

-

température gradient (Km−1)

- I V(P):

-

Ivantsov function (P exp(P)E1(P))

- P :

-

solute Péclet number = VSR/2D

- R :

-

tip radius (m)

- T EU :

-

eutectic temperature (K)

- T F :

-

melting point of pure substance (K)

- T G :

-

arrest growth temperature (K)

- T L :

-

liquidus temperature (K)

- V ab :

-

absolute stability velocity (ms−1)

- V s :

-

solidification front velocity (ms−1)

- a :

-

material constant

- b :

-

material constant

- k :

-

distribution coefficient (CS/CL)

- k :

-

constant

- m :

-

liquidus slope (K/at %, K/wt %)

- n :

-

exponent

- p :

-

complementary distribution coefficient (1−k)

- τ :

-

Gibbs-Thomson coefficient (σ/Δsf) (Km)

- Δs f :

-

entropy of fusion per mole (J mol−1K−1)

- ΔT 0 :

-

liquidus-solidus range at C0(TS−TL) (K)

- Λ 1 :

-

cell spacing (m)

- σ :

-

solid/liquid interface energy

- π :

-

3.1416

- ξc :

-

constant = 1−(2k/[1+(2π/P)2]1/2−1+2k)

References

W. J. Boettinger, S. R. Coriel and R. F. Sekerka, Mater. Sci. Engng 65 (1984) 27.

W. Kurz and D. J. Fisher, Acta Metall. 29 (1981) 11.

V. Laxmanan, ibid. 33 (1985) 1023.

Idem., ibid. 33 (1985) 1037.

W. Kurz, B. Giovanola and R. Trivedi, ibid. 34 (1986) 823.

R. Trivedi and W. Kurz, ibid. 34 (1986) 1663.

W. J. Boettinger, D. Shechtman, R. J. Schaefer and F. S. Biancaniello, Metall. Trans. 15A (1984) 55.

J. A. Juarez-Islas and H. Jones, Acta Metall. 35 (1987) 499.

Idem., Inst. Metals 421 (1988) 492.

J. A. Juarez-Islas, H. Jones and W. Kurz, Mater. Sci. Engng 98 (1988) 201.

H. Esaka and W. Kurz, J. Crystal Growth 69 (1984) 362.

H. D. Brody and M. C. Flemings, Metal Trans. 12A (1981) 965.

M. Hansen and K. Anderko (eds), “Constitution of Binary Alloys” (McGraw-Hill, New York, 1958).

R. J. Schaefer, S. R. Coriell, R. Mehrabian, C. Fenimore and F. S. Biancaniello, in “Rapidly Solidified Amorphous and Crystalline Alloys”, edited by B. H. Kear, B. C. Giessen and M. Cohen, Materials Research Society Symposium Proceedings, Vol. 8 (Elsevier, Amsterdam, 1982) p. 79.

W. W. Mullins, A. J. McAlister, R. J. Schjaefer, L. A. Bendersky, F. S. Biancaniello and D. L. Moffat, Metall. Trans. 18A (1987) 385.

K. A. Jackson and J. D. Hunt, Trans. Met. Soc. AIME 236 (1966) 1129.

W. Kurz and D. J. Fisher, Int. Met. Rev. 24 (1979) 177.

W. Kurz, Z. Metallkde. 69 (1978) 433.

J. D. Hunt, in “Proceedings of the Conference on Solidification and Casting of Metals”, Sheffield, July 1977 (Metals Society, London, 1979) pp. 3–9.

T. Takahashi, A. Kamio and Nguyen An Trung, J. Crystal Growth 24/25 (1974) 477.

M. Sugiyama, T. Umeda and H. Kato, J. Jpn Inst. Light Metals 24 (1974) 263.

J. A. Juarez-Islas, PhD thesis, Sheffield University (1986).

R. H. Ewing, Phil. Mag. 25 (1972) 779.

C. J. Smithells and E. A. Brandes (eds), “Metals Reference Book”, 5th Edn (Butterworths, London, 1976).

J. A. Eady et al, J. Aust. Inst. Metals 28 (1975) 23.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Juarez-Islas, J.A. Analysis of the microstructure obtained by using unidirectional solidification, tungsten inert gas weld and laser surface melt traversing techniques in Al-Mn alloys. J Mater Sci 26, 5004–5012 (1991). https://doi.org/10.1007/BF00549884

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF00549884