Abstract

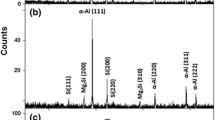

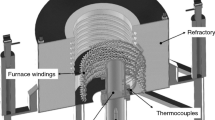

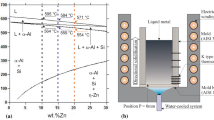

Unsteady solidified microstructures of the Al-15 wt pct Si-1.5 wt pct Mg alloy under two degrees of melt superheating are examined: 4 and 21 pct above the alloy liquidus temperature. The dendritic array and the eutectic mixture have been investigated, which are affected not only by the solidification kinetics but also by the melt superheating. The directional solidification experiments permitted that aligned Al-rich dendrites could be formed for both high- and low-melt superheatings. These dendrites appear as ‘islands’ isolated from each other and dispersed within the α-Al+Si+Mg2Si eutectic matrix. Such configuration arises in samples under the entire range of examined cooling rates, i.e., from 0.5 to 50 K/s. Directionally solidified samples having different α-Al dendrite interphase spacings have been characterized and subjected to tensile tests. Such microstructural spacings translate the effectiveness in blocking the dislocations motion during loading, which is promoted mainly by the dendritic/eutectic boundaries. This mechanism is especially operative since the applied tensile load is perpendicular to the dendritic growth path. As such, the evolution of tensile properties as a function of these spacings was assessed. Both elongation (δ) and the ultimate strength (σu) are enhanced nearly by 40 pct due to the reduction in the dendrite interphase spacing. The highest properties (σu: ~ 310 MPa and δ: ~ 7 pct) are associated with a microstructure formed by aligned dendrites with 70 μm in spacing embedded in a eutectic mixture. Three factors appear to contribute to the higher strength values observed for the alloy processed under lower-melt superheating, i.e., higher fraction of dendrites, solid solution strengthening of Mg in α-Al, and finer eutectic Si spacing.

Similar content being viewed by others

References

[1] P. Pandey, S. Kashyap, CS. Tiwary, K Chattopadhyay: Metall Mater Trans A, 2017, vol. 48, pp. 5940-5950.

J.W. Bray: ASM Metals Handbook, 10th ed., ASM International, Ohio, 1976

V.S. Zolotorevsky, N.A Belov, M.V. Glazoff: Casting Aluminum Alloys, vol. 12, Elsevier, Amsterdam, 2007.

[4] R.V. Reyes, TS Bello, R Kakitani, TA Costa, A Garcia, N Cheung, JE Spinelli: Mater Sci Eng A, 2017, vol. 685, pp. 235-243.

[5] M. Tebib, F Ajersch, AM Samuel, X-G Chen: Metall Mater Trans, 2013, vol. 44, pp. 4282-4295.

[6] K Matsuura, M Kudoh, H Kinoshita: Mater Chem Phys, 2003, vol. 81, pp. 393-395.

[7] L Lasa, JM Rodriguez-Ibabe: Mater Sci Eng A, 2003, vol. 363, pp. 193-202.

[8] E. Sjölander, S.Seifeddine: J. Mater. Process. Technol., 2010, vol. 210, pp. 1249-1259.

D.L. Zhang, L.H. Zheng, D.H. Stjohn: J. Light Met., 2002, vol. 2, pp. 27-36.

[10] L.G. Hou, H. Cui, Y.H. Cai, J.S. Zhang: Mater. Sci. Eng. A, 2009, vol. 527, pp. 85-92.

[11] E.R. Wang, X.D. Hui, G.L. Chen: Mater. Des., 2011, vol. 32, pp. 4333-4340.

A. Mandal, M.M. Makhlouf: Improving Aluminum Casting Alloy and Process Competitiveness, Report no. 07-02, ACRC, Durango, 2007.

A. Mandal, M.M. Makhlouf: Proceedings of 113th TMS Annual Meeting, San Francisco, 2009, pp. 57-62.

[14] A Mandal, MM Makhlouf: Int J Cast Metal Res, 2010, vol. 23, pp. 303-309.

[15] A Hekmat-Ardakan, F Ajersch: J Mater Process Tech, 2010, vol. 210, pp. 767-775.

[16] Y. Wu, H. Liaon, K. Zhou: Mater. Sci. Eng. A, 2014, vol. 602, pp. 41-48.

[17] A. Niklas, A. Bakedano, S. Orden, M. da Silva, E. Nogués, A.I. Fernández-Calvo: Materials Today: Proceedings, 2015, vol. 2, pp. 4931-4938.

[18] S. Seifeddine, S. Johansson, I.L. Svensson: Mater. Sci. Eng. A, 2008, vol. 490, pp. 385-390.

[19] PR Goulart, WR Osório, JE Spinelli, A Garcia: Mater Manuf Process, 2007, vol. 22, pp. 328-332.

[20] PR Goulart, JE Spinelli, WR Osorio, A Garcia: Mater. Sci. Eng. A, 2006, vol. 421, pp. 245-253.

E. Ghassemali, M. Riestra, T. Bogdanoff, B.S. Kumar, S. Seifeddine: International Conference on the Technology of Plasticity, ICTP, Cambridge, 2017, pp. 17–22.

[22] J Zhang, Z Fan, YQ Wang, BL Zhou: Mater. Sci. Eng. A, 2000, vol. 281, pp.104-122.

[23] QC Jiang, HY Wang, Y Wang, BX Ma, JG Wang: Mater. Sci. Eng. A, 2005, vol. 392, pp. 130-135.

[24] R Hadian, M Emamy, N Varahram, N Nemati: Mater. Sci. Eng. A, 2008, vol. 490, pp. 250-257.

[25] QD Qin, WX Li, KW Zhou, SL Qiu, YG Zhao, Mater. Sci. Eng. A, 2011, vol. 527, pp. 2253–2257.

A. Kearney and E.L. Rooy: ASM Handbook - Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, ASM Handbook Committee, 1990, vol. 2, pp. 123–151.

M. Okayasu, S. Takeuchi, T. Shiraishi: Int. J. Cast. Metal. Res., 2013, vol. 26, pp.105-113

[28] Z. Qian, X. Liu, D. Zhao, G. Zhang: Mater. Lett., 2008, vol. 62, pp. 2150–2153.

[29] M. V. Canté, J. E. Spinelli, N. Cheung, A. Garcia: Met. Mater. Int., 2010, vol. 16, pp. 39-49.

[30] DM Rosa, JE Spinelli, IL Ferreira, A Garcia: J Alloys Compd, 2006, vol. 422, pp.227-238.

[31] M. Gunduz, E. Çadirli: Mater. Sci. Eng. A, 2002, vol. 327, pp. 167-185.

[32] E. Çadirli, U. Büyük, S. Engin, H. Kaya. J. Alloys Compd., 2017, vol. 694, pp. 471-479.

[33] K.A. Jackson, J.D. Hunt: Trans. Metall. Soc. AIME, 1966, vol. 236, pp. 1129-1142.

[34] Y. Birol: Mater. Sci. Eng. A, 2013, vol. 559, pp. 394-400.

[35] E. Samuel, B. Golbahar, A.M. Samuel, H.W. Doty, S. Valtierra, F.H. Samuel: Mater. Des., 2014, vol. 56, pp. 468-479.

E.L. Rooy: Aluminum and Aluminum Alloys, Casting 9th edition, vol. 15, Metals Handbook, ASM international, 1988, pp. 743–70.

[37] G Zhang, J Zhang, B Li, W Cai: Prog Nat Sci-Mater, 2011, vol. 21, pp. 380-385.

Acknowledgments

The authors are grateful to FAPESP (São Paulo Research Foundation, Brazil: grant 2017/12741-6) and National Council for Scientific and Technological Development – CNPq for their financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 1, 2018.

Rights and permissions

About this article

Cite this article

Kakitani, R., Reyes, R.V., Garcia, A. et al. Effects of Melt Superheating on the Microstructure and Tensile Properties of a Ternary Al-15 Wt Pct Si-1.5 Wt Pct Mg Alloy. Metall Mater Trans A 50, 1308–1322 (2019). https://doi.org/10.1007/s11661-018-5058-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-5058-5