Abstract

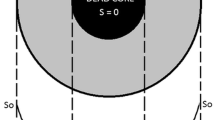

The transient state analysis of the consecutive sequence of reactions S → P 1 → P 2 taking place inside a porous spherical coimmobilized biocatalyst is discussed for the case in which each step follows Michaelis Menten type kinetics. The theoretical analysis includes intraparticle diffusional limitations. The model equations are solved by the explicit finite difference method. The effect of various parameters of importance on the batch reactor performance is discussed. Comparison of the model with experimental results has been shown.

Similar content being viewed by others

Abbreviations

- c p :

-

Dimensionless substrate concentration inside the particle, (s p/ss o)

- c pi, j :

-

Dimensionless substrate concentration inside the particle at i, j

- c s :

-

Dimensionless substrate concentration at the surface of the particle, (s s/s 0)

- d p cm:

-

particle diameter

- D s, D p cm2/s:

-

Diffusion coefficient of the substrate S and intermediate P 1 inside the particle respectively

- h :

-

Space step size inside the particle

- i :

-

Grid point inside the particle

- j :

-

Grid point along the time coordinate

- k :

-

Time step size

- K m1, K m2 g/l:

-

Michaelis constants for the first and second reaction respectively

- K I1,K I2 g/l:

-

Substrate inhibition parameters for first and second reaction respectively

- P m g/l:

-

Product inhibition parameter for the second reaction

- P 1p , P 1s g/l:

-

Concentration of the intermediate inside the particle and at the surface of the particle respectively

- P 2p , P 2s g/l:

-

Concentration of the product P 2 inside the particle and at the surface of the particle respectively

- p 1p :

-

Dimensionless intermediate concentration inside the particle, (p 1p/s0)

- p 1s :

-

Dimensionless intermediate concentration at the surface of the particle, (p 1s /S 0)

- P 2p :

-

Dimensionless product concentration inside the particle, (p 2p /S0)

- p 2s :

-

Dimensionless product concentration at the surface of the particle, (p 2s/S0)

- p 1pi, j :

-

Dimensionless intermediate concentration inside the particle at i, j

- P 2pi, j :

-

Dimensionless product concentration inside the particle at i, j

- q :

-

Ratio of diffusion coefficients, D p/D s

- r cm:

-

Radial position inside the particle

- R cm:

-

Radius of the pellet

- S 0 g/l:

-

Initial substrate concentration in the bulk liquid

- S p g/l:

-

Substrate concentration inside the particle

- S s g/l:

-

Substrate concentration at the surface of the particle

- t s:

-

Time,

- V max1 g/(ls):

-

Maximum reaction velocity for the first reaction

- V max2 g/(ls):

-

Maximum reaction velocity for the second reaction

- y :

-

Dimensionless radial distance, (r/R)

- y 1, j :

-

Dimensionless radial distance at i, j

- г1 :

-

Parameter, S 0/K m1

- г2 :

-

Parameter, S 0/K m2

- г I1 :

-

Parameter, S 0/K I1

- г I2 :

-

Parameter, S 0/K I2

- г I3 :

-

Parameter, S 0/P m

- τ :

-

Dimensionless time defined as (D s t/R 2)

- φ 21 :

-

V max1R 2/Km1Ds

- φ 22 :

-

V max2R 2/Km2Ds

References

Mosbach, K.: Togetherness through immobilisation. In: Bohak, Z.; Sharon, N. (Eds.): Biotechnological applications of proteins and enzymes, pp 141–152 London: Academic Press 1977

Buchholz, K.; Godelmann B.: Mackrokinetics and operational stability of immobilized glucose oxidase and catalase. Biotechnol. Bioeng. 20 (1978) 1201–1220

Chiang, L. C.; Hsiao, H. Y.; Veng, P. P.; Chen, L. F.; Tsao, G. T.: In: Scott, E. D. (Ed.): Third Symposium on Biotechnology in Energy Production and Conservation, pp 263: Wiley, New York, 1981

Chithra, N.: Studies on the conversion of starch to ethanol using coimmobilized amyloglucosidase and Saccharomyces cerevisiae in bioreactors. Ph. D. Thesis, IIT Madras 1989

Hägerdal, B.: An enzyme coimmobilized with a microorganism: The conversion of cellobiose to ethanol using β — glucosidase and Saccharomyces cerevisiae in calcium alginate gels. Biotechnol. Bioeng. 26 (1984) 771–774

Hahn-Hägerdal, B.: Comparison between immobilized Kluyveromyces fragilis and Saccharomyces cerevisiae coimmobilized with β-galactosidase, with respect to continuous ethanol production from concentrated whey permeate. Biotechnol. Bioeng. 27 (1985) 914–916

Lawrence, R. L.; Okay, V.: Diffusion and reaction in a double enzyme supported catalyst. Biotechnol. Bioeng. 25 (1973) 217–221

Newirth, T. L.; Diegelman, M. A.; Pye, E. K.; Kallen, R. G.: Multiple immobilized enzyme reactors: Determination of pyruvate and phosphoenol pyruvate concentrations using immobilized lactate dehydrogenase and pyruvate kinase. Biotechnol. Bioeng. 15 (1973) 1089–1100

Tanaka, H.: Kurosawa, H.; Murakami, H.: Ethanol production from starch by a coimmobilized mixed culture system of Asper gillus awamori and Zymomonas mobilis. Biotechnol. Bioeng. 28 (1986) 1761–1768

Goldman, R.; Katchalski, E.: Kinetic behavior of two enzyme membrane carrying out a consecutive set of reactions. J. Theor. Biol. 32 (1971) 243–257

Krishna, R.; Ramachandran, P. A.: Analysis of diffusional effects in immobilized two enzyme systems. J. Appl. Chem. Biotechnol. 25 (1975) 623–640

Ramachandran, P. A.; Krishna, R.; Panchal, C. B.: Analysis of immobilized multi-enzyme reaction systems with Michaelis-Menten kinetics. J. Appl. Chem. Biotechnol. 26 (1976) 214–223

Hall, R. D.: Jl. Inst. Brewing 62 (1956) 222–226

Miller, G. L.: Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31 (1959) 426–428

Ghose, T. K.; Bandhyopadhyay, H. H.: Rapid ethanol fermentation in immobilized yeast cell reactor. Biotechnol. Bioeng. 22 (1980) 1489–1496

Chithra, N.; Baradarajan, A.: Direct conversion of starch hydrolysate to ethanol using a coimmobilizate of amyloglucosidase and Saccharomyces cerevisiae in batch stirred tank reactor. Bioprocess Engg. 7 (1992) 265–267

Smith, G. D.: Numerical Solution of Partial Differential Equations, Oxford University Press (1966)

Hodge, H. M.; Hildebrandt, F. M.: Alcoholic fermentation of molasses. In: Underkofler, L. A.: Hicky, R. J. (Eds.): Industrial Fermentations 1, p 73, 1954

Maiorella, B. L.: Ethanol. In: Murray-Moo Young (Ed.): Comprehensive Biotechnology vol. 3, p 861 Pergamon Press, 1985

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chithra, N., Baradarajan, A. Transient state analysis of biochemical reactor using coimmobilized system. Bioprocess Engineering 10, 83–89 (1994). https://doi.org/10.1007/BF00393390

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00393390