Abstract

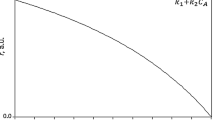

This paper presents a model of a batch stirred tank reactor with spherical catalyst particles as microreactors. The model involves three regions: an array of porous enzyme-loaded microreactors where enzyme reaction as well as mass transfer by diffusion take place, a diffusion limiting region surrounding the particles and a convective region where the substrate is of uniform concentration. The microbioreactors are mathematically modeled by a two-compartment model based on reaction–diffusion equations containing a nonlinear term related to the Michaelis–Menten enzyme kinetics. The influence of the physical and kinetic parameters of the microbioreactors on the transient effectiveness of the bioreactor system is numerically investigated in a wide range of model parameters. The numerical simulation was carried out using the finite difference technique. The simulation results show non-monotonic effect of the initial substrate concentration and nonlinear effects of the internal and external diffusion limitations as well as adsorption capacity of the microreactors on the transient effectiveness.

Similar content being viewed by others

References

A.E. Al-Muftah, I.M. Abu-Reesh, Effects of simultaneous internal and external mass transfer and product inhibition on immobilized enzyme-catalyzed reactor. Biochem. Eng. J. 27(2), 167–178 (2005)

M. Al-Shannag, Z. Al-Qodah, J. Herrero, J.A. Humphrey, F. Giralt, Using a wall-driven flow to reduce the external mass-transfer resistance of a bio-reaction system. Biochem. Eng. J. 38(3), 554–565 (2008)

I. Andrés, Enzyme Biocatalysis: Principles and Applications (Springer, Dordrecht, 2008)

R. Aris, Mathematical Modeling: A Chemical Engineer’s Perspective (Academic Press, London, 1999)

R. Baronas, F. Ivanauskas, J. Kulys, Mathematical modeling of biosensors based on an array of enzyme microreactors. Sensors 6(4), 453–465 (2006)

R. Baronas, J. Kulys, L. Petkevičius, Modelling the enzyme catalysed substrate conversion in a microbioreactor acting in continuous flow mode. Nonlinear Anal. Model. Control 23(3), 437–456 (2018)

P.N. Bartlett, Bioelectrochemistry: Fundamentals. Experimental Techniques and Applications (Wiley, Chichester, 2008)

L.A. Belfiore, Transport Phenomena for Chemical Reactor Design (Wiley, Hoboken, 2003)

C.M. Bidabehere, J.R. García, U. Sedran, Use of stirred batch reactors for the assessment of adsorption constants in porous solid catalysts with simultaneous diffusion and reaction. Theor. Anal. Chem. Eng. Sci. 61(6), 2048–2055 (2006)

C.M. Bidabehere, J.R. García, U. Sedran, Transient effectiveness factor in porous catalyst particles. Application to kinetic studies with batch reactors. Chem. Eng. Res. Des. 118, 41–50 (2017)

C.M. Bidabehere, J.R. García, U. Sedran, Transient effectiveness factor. Simultaneous determination of kinetic, diffusion and adsorption equilibrium parameters in porous catalyst particles under diffusion control conditions. Chem. Eng. J. 345, 196–208 (2018)

C.M. Bidabehere, U. Sedran, Transient effectiveness factors in the dynamic analysis of heterogeneous reactors with porous catalyst particles. Chem. Eng. Sci. 137, 293–300 (2015)

J. Biswas, D. Do, P. Greenfield, J.M. Smith, Evaluation of bidisperse diffusivities and tortuosity factors in porous catalysts using batch and continuous adsorbers: a theoretical study. Appl. Catal. 22(1), 97–113 (1986)

N. Bortone, M. Fidaleo, M. Moresi, Internal and external mass transfer limitations on the activity of immobilised acid urease derivatives differing in enzyme loading. Biochem. Eng. J. 82, 22–33 (2014)

D. Britz, R. Baronas, E. Gaidamauskaitė, F. Ivanauskas, Further comparisons of finite difference schemes for computational modelling of biosensors. Nonlinear Anal. Model. Control 14(4), 419–433 (2009)

D. Britz, J. Strutwolf, Digital Simulation in Electrochemistry. Monographs in Electrochemistry, 4th edn. (Springer, Cham, 2016)

N. Casas, P. Blánquez, T. Vicent, M. Sarrà, Mathematical model for dye decoloration and laccase production by Trametes versicolor in fluidized bioreactor. Biochem. Eng. J. 80, 45–52 (2013)

H.S. Choonia, S. Lele, Kinetic modeling and implementation of superior process strategies for \(\beta \)-galactosidase production during submerged fermentation in a stirred tank bioreactor. Biochem. Eng. J. 77, 49–57 (2013)

L. Coche-Guerente, P. Labbé, V. Mengeaud, Amplification of amperometric biosensor responses by electrochemical substrate recycling. 3. Theoretical and experimental study of the phenol–polyphenol oxidase system immobilized in laponite hydrogels and layer-by-layer self-assembled structures. Anal. Chem. 73(14), 3206–3218 (2001)

M.E. Davis, R.J. Davis, Fundamentals of Chemical Reaction Engineering (McGraw-Hill, New York, 2003)

D.D. Do, P.F. Greenfield, The concept of an effectiveness factor for reaction problems involving catalyst deactivation. Chem. Eng. J. 27(2), 99–105 (1983)

P.M. Doran, Bioprocess Engineering Principles, 2nd edn. (Academic Press, Waltham, 2013)

D.A. Edwards, B. Goldstein, D.S. Cohen, Transport effects on surface-volume biological reactions. J. Math. Biol. 39(6), 533–561 (1999)

E. Fossas, R.M. Ros, J. Fabregat, Sliding mode control in a bioreactor model. J. Math. Chem. 30(2), 203–218 (2001)

B. Godongwana, Effectiveness factors and conversion in a biocatalytic membrane reactor. PLoS ONE 11(4), e0153,000 (2016)

I. Grubecki, External mass transfer model for hydrogen peroxide decomposition by terminox ultra catalase in a packed-bed reactor. Chem. Process Eng. 38(2), 307–319 (2017)

J. Iqbal, S. Iqbala, C.E. Müller, Advances in immobilized enzyme microbioreactors in capillary electrophoresis. Analyst 138(11), 3104–3116 (2013)

E. Jones, K. McClean, S. Housden, G. Gasparini, I. Archer, Biocatalytic oxidase: batch to continuous. Chem. Eng. Res. Des. 90, 726–731 (2012)

V. Kasche, A. Kapune, H. Schwegler, Operational effectiveness factors of immobilized enzyme systems. Enzyme Microb. Technol. 1(1), 41–46 (1979)

G. Marroquín, J. Ancheyta, C. Esteban, A batch reactor study to determine effectiveness factors of commercial HDS catalyst. Catal. Today 104(1), 70–75 (2005)

V.M. PonRani, L. Rajendran, Mathematical modelling of steady-state concentration in immobilized glucose isomerase of packed-bed reactors. J. Math. Chem. 50(5), 1333–1346 (2012)

J.K. Poppe, R. Fernandez-Lafuente, R.C. Rodrigues, M.A.Z. Ayub, Enzymatic reactors for biodiesel synthesis: present status and future prospects. Biotechnol. Adv. 33(5), 511–525 (2015)

W.H. Press, S.A. Teukolsky, W.T. Vetterling, B.P. Flannery, Numerical Recipes: The Art of Scientific Computing, 3rd edn. (Cambridge University Press, Cambridge, 2007)

J.B. Rawlings, J.G. Ekerdt, Chemical Reactor Analysis and Design Fundamentals, 2nd edn. (Nob Hill Publishing, LLC, Madison, 2015)

U. Rinas, H. El-Enshasy, M. Emmler, A. Hille, D.C. Hempel, H. Horn, Model-based prediction of substrate conversion and protein synthesis and excretion in recombinant Aspergillus niger biopellets. Chem. Eng. Sci. 60(10), 2729–2739 (2005)

A. Sagiv, Exact solution of mass diffusion into a finite volume. J. Membr. Sci. 186(2), 231–237 (2001)

D. Schäpper, M.N.H.Z. Alam, N. Szita, A.E. Lantz, K.V. Gernaey, Application of microbioreactors in fermentation process development: a review. Anal. Bioanal. Chem. 395(3), 679–695 (2009)

T. Skybová, M. Přibyl, P. Hasal, Mathematical model of decolourization in a rotating disc reactor. Biochem. Eng. J. 93, 151–165 (2015)

M. Velkovsky, R. Snider, D.E. Cliffel, J.P. Wikswo, Modeling the measurements of cellular fluxes in microbioreactor devices using thin enzyme electrodes. J. Math. Chem. 49(1), 251–275 (2011)

J. Villadsen, J. Nielsen, G. Lidén, Bioreaction Engineering Principles. Monographs in Electrochemistry, 3rd edn. (Springer, New York, 2011)

H.J. Vos, P.J. Heederik, J.J.M. Potters, K.C.A.M. Luyben, Effectiveness factor for spherical biofilm catalysts. Bioprocess Eng. 5(2), 63–72 (1990)

Acknowledgements

The work of R. Baronas and L. Petkevičius was supported by the Research Council of Lithuania under Grant No. S-MIP-17-98.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baronas, R., Kulys, J. & Petkevičius, L. Computational modeling of batch stirred tank reactor based on spherical catalyst particles. J Math Chem 57, 327–342 (2019). https://doi.org/10.1007/s10910-018-0954-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10910-018-0954-x