Abstract

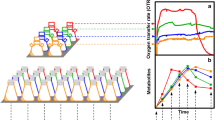

Fermentations of Xanthomonas campestris, NRRL B-1459, were carried out in a bubble column fermentor (BCF) and in a stirred tank fermentor (STF) to allow comparison of representative variables measured during the microbial growth and the gum production.

The microbial growth phase was described by a logistic rate equation where maximum cell concentration was provided by nitrogenous compounds balance. The average value of the maximum specific growth rate was higher in the bubble column (μ M =0.5 h−1) than in the stirred reactor (μ M =0.4 h−1).

The upper values of xanthan yield (Y g-x =0.65 kg xanthan/kg glucose; Y O 2−x xanthan/kg oxygen) and specific production rate (q x =0.26 kg xanthan/kg biomass · h) were measured when the oxygen transfer coefficient was kept up above 80 h−1 in the STF fermentor. In the bubble column the fermentation achieved in the same culture medium lasts two times longer than in the stirred aerated tank; this was attributed to the low value of the oxygen transfer coefficient (K L a =20 h−1) at the beginning of the gum synthesis phase. The results obtained in the stirred tank were the basis to estimate the optimal biomass concentration which enables to achieve a culture in non-limiting oxygen transfer conditions.

Nevertheless, the transfer characteristics were more homogeneous in the bubble column than in the stirred tank where dead stagnant zones were observed. This is of primary importance when establishing fermentation kinetics models.

Similar content being viewed by others

Abbreviations

- BCF:

-

Bubble column fermentor

- C b kg/m3 :

-

Biomass concentration. C bo is the initial value, C b max the value in the stationary phase and C b opt the optimal value

- C g kg/m3 :

-

Glucose concentration. C go is the initial value of the first period and C′ go the initial value of the second period

- C aN kg nitrogen/m3 :

-

Amino acid concentration in the fermentation medium expressed as nitrogen equivalent

- C pN kg nitrogen/m3 :

-

Protein concentration in the fermentation medium expressed as nitrogen equivalent

- C N kg nitrogen/m3 :

-

Nitrogen concentration in the medium. C No is the initial value

- C O 2 mol/m3 :

-

Dissolved oxygen concentration at pressure and temperature of the system

- C x kg/m3 :

-

Xanthan concentration

- C * mol/m3 :

-

Saturation concentration of dissolved oxygen at pressure and temperature of the system

- C * o mol/m3 :

-

Saturation concentration of dissolved oxygen at temperature of the system under 1 atmosphere saturated air

- G e mol/s:

-

Molar gas flow rate at orifice

- G v Nm3/s:

-

Normal volumetric gas flow rate

- K L a h−1 :

-

Volumetric oxygen transfer coefficient

- N min−1 :

-

Impeller rotation speed

- Q r :

-

Respiratory quotient

- q i kg/kg biomass · h:

-

Specific conversion rate of i

- q′ i mol/kg biomass · h:

-

Specific conversion rate of i

- r i kg/(m3 · h):

-

Consumption or synthesis rate of i

- r′ i mol/(m3 · h):

-

Consumption or synthesis rate of i

- r i opt kg/(m3 · h):

-

Optimal consumption or synthesis rate of i

- STF:

-

Stirred tank fermentor

- t h:

-

Time

- vvm:

-

Volume of gas per liquid volume per minute

- y i-j kg j/kg i:

-

Weight yield of compound j from compound i

- y is :

-

Molar fraction of component i in exit gas phase

- μ M h −1 :

-

Maximum specific growth rate

- Δ :

-

Difference

- o :

-

Initial conditions

- M :

-

Maximum value

- e :

-

Fermentor entrance

- s :

-

Fermentor exit

- a :

-

Amino acid

- b :

-

Biomass

- g :

-

Glucose

- N :

-

Nitrogen

- p :

-

Protein

- x :

-

Xanthan

References

Kennedy, J. F.; Bradshaw, I. J.: Production, properties and applications of xanthan. Progress Ind. Miocrobol. 19 (1984) 319–365

Gabriel, A.: Economic value of biopolymers and their use in enhanced oil recovery. In: Berkeley, R. C. W. (Ed.): Microbial Polysaccharides and Polysaccharases. pp. 191–204. New York: Academic Press for the Society for General Microbiology (1979)

Souw, P.; Demain, A. L.: Nutritional studies on xanthan production by Xanthomonas campestris NRRL B-1459. Appl. Environ. Microbiol. 6 (1979) 1186–1192

Dussap, C. G.; Gros, J. B.: Fermenteurs agités sans organe d'agitation mecanique — Application à la production de polysaccharides exocellulaires. Bulletin de la Société Chimique de France. 6 (1985) 1075–1082

Pons, A.; Dussap, C. G.; Gros, J. B.: Modelling Xanthomonas campestris batch fermentations in a bubble column. Biotechn. Bioeng. 33 (1989) 394

Pons, A.: Analyse de la production de xanthane par Xanthomonas camprestris NRRL B-1459 en cuve agitée aérée et en colonne à bulles à l'aide d'un modèle structuré. Thèse de Docteur-Ingénieur, Université Biaise Pascal (Clermont II), France, 1987

Dussap, C. G.; Decorps, J.; Gros, J. B.: Transfert d'oxygène en présence de polysaccharides exocellulaires dans un fermenteur agité aéré et dans un fermenteur air-lift. Entropie 123 (1985) 11–20

Silman R. W.; Bagley, E. B.: The viscositat: producstat method of control in continuous fermentation. Biotechn. Bioeng. 21 (1979) 173–179

Jeanes, A. J.; Rogovin, P.; Cadmus, M. C.; Silman R. W.; Knuston, C. A.: Polysaccharide (xanthan) of Xanthomonas campestris NRRL B-1459 — Procedures for culture maintenance and polysaccharide production, purification and analysis. ARS-NC-51, Agricultural Research Service, U.S. Dept of Agriculture, Peria IL, 1976

Lowry, O. H.; Rosenbrough, N. J.; Farr A. L.; Randall, R. J.: Protein measurement with the Folin phenol reagent. J. Biol. Chem. 193 (1951) 265–275

Sumner, J. B.; Howell, S. F.: A method for determination of invertase activity. J. Biol. Chem. 108 (1935) 51–54

Lee, Y. A.; Takahashi, T.: An improved colorimetric determination of amino acids with the use of ninhydrin. Anal. Biochem. 14 (1966) 71–77

Dussap, C. G.; Bonhour, E.; Gros, J. B.: Utilisation du modèle de solution de Flory-Huggins pour calculer les solubilités de CO2 et O2 en milieux fermentaires. In: Bioreacteurs. Actes du 11e Colloque de la Section de Microbiologie Industrielle et de Biotechnologie de la SFM (avril 1986), pp. 269–275

Lehmann, J. K.: Comparative tests for fermentation. In: Rehm, H. J.; Reed, G. (Eds.): Biotechnology, vol. 2, pp. 617–620. Weinheim: Verlag Chemie

Pinches, A.; Pallent, L. J.: Rate and yield relationships in the production of xanthan gum by batch fermentations using complex and chemically defined growth media. Biotechn. Bioeng. 28 (1986) 1484–1496

Weiss R. M.; Ollis, D. F.: Extracellular microbial polysaccharides. I. Substrate, biomass and product kinetic-Equations for batch xanthan gum fermentation. Biotechn. Bioeng. 22 (1980) 859–873

Dussap, C. G.: Etude thermodynamique et cinétique de la production de polysaccharides microbiens par fermentation en limitation par le transfert d'oxygène. Modèle structuré de la production de xanthane. Thèse de Doctorat es Sciences Physiques, Université Blaise Pascal (Clermont II), France, 1988

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Pons, A., Dussap, C.G. & Gros, J.B. Xanthan batch fermentations: compared performances of a bubble column and a stirred tank fermentor. Bioprocess Engineering 5, 107–114 (1990). https://doi.org/10.1007/BF00388188

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00388188