Abstract

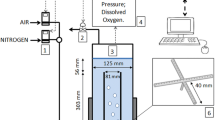

This report describes the design and use of a new type of Continuous Plug Flow Reactor (CPFR). The reactor comprises a continuous glass tube (diameter of 19 mm) arranged into a spiral (0.4 m external diameter) consisting of five loops, which rotate around an axle. The CPFR has advantages over other reactors in that continuous fermentation is possible without dilution of the culture and biomass or metabolite yield is increased. In addition temperature and water activity may be adjusted to a different optimum level for each physiological stage of the cultivated microorganism.

Similar content being viewed by others

Abbreviations

- a (m2):

-

specific surface of the transfer

- c (cell ml−1):

-

cellular concentration at t time

- c 0 (cell ml−1):

-

cellular concentration at t=0

- c ex (kg m−3):

-

output concentration of compound i

- c in (kg m−3):

-

input concentration of compound i

- C 0 (g l−1):

-

concentration of methylene blue at t=0

- C ex (gl−1):

-

concentration of methylene blue at t time

- D (h−1):

-

dilution rate of the reactor

- F (m3 s−1):

-

volumetric flow rate

- F ex (m3 s−1):

-

output volumetric flow rate

- F in (m3 s−1):

-

input volumetric flow rate

- k L(m−2 s−1):

-

mass transfer coefficient of O2

- O (mol l−1):

-

O2 concentration in the liquid

- O ⋆eff (moll−1):

-

effective O2 concentration at saturation

- r i(kg m−1s−1):

-

rate of production of compound i

- t (s):

-

time

- ¯t (s):

-

theoretical mean residence time of the dye in a loop

- t s(s):

-

experimental residence time of the dye in a loop

- V (m3):

-

liquid volume in one loop for this plug flow reactor or reaction volume for a usual reactor

- v z(m s−1):

-

apparent flow velocity

- z (m):

-

coordinate

- μ (h−1):

-

mean growth rate

References

Loncin, M. (Ed.): Génie Industriel Alimentaire, pp. 199–211. Paris: Masson 1966

Moser, A. (Ed.): Bioprocess Technology, Kinetics and Reactors. Wien: Springer-Verlag 1988

Reusser, F.: Theoretical design of continuous antibiotic fermentation units. Appl. Microbiol. 9 (1961) 361–366

Jourdain, N.: Production continue de composés d'arômes par microoganismes retenus, Thèse de docteur ingénieur Sciences alimentaires, Université des Sciences et Techniques du Languedoc Montpellier, 1985

Mattiasson, B.; Holst, O.: Simultaneous fermentation and separation, 8th Intern. Biotechnol. Symp., Paris, Proceedings. 1 (1988) 513–522

Russel, T.W.F.; Dunn, I.J.: The tubular loop batch fermentor: basic concepts. Biotechnol. Bioeng. 16 (1974) 1261–1272

Pirt, S.J.; Lee, Y.K.; Walach, M.R.; Pirt, M.W.; Balyuzi, H.H.M.; Bazin, M.J.: A tubular bioreactor for photosynthetic production of biomass from carbon dioxyde: design and performance. J. Chem. Tech. Biotechnol. 33B (1983) 35–58

Scriban, R. (Ed.): Biotechnologie. Paris: Technique et Documentation Lavoisier 1984

Gervais, P.; Bazelin, C.; Voilley, A.: Patterns of aeration in a solid substrate fermentor through the study of the residence time distribution (RTD) of a volatil tracer. Biotechnol. Bioeng. 28 (1986) 1540–1543

Bull, A.T. (Ed.): The Principles, Applications and Regulations of Biotechnology in Industry, Agriculture and Medicine. Oxford: Pergamon Press 1984

Rizzi, M.; Baltes, M.; Theobald, U.; Reuss, M.: Structured metabolic modelling applied to dynamic simulation of the Crabtree effect and Pasteur effect in baker's yeast. In: Christiansen C., Munck L. and Villadsen J. (Eds) 5th European Congress on Biotechnology Abstract book. Copenhague: Munksgaard 1990

Gervais, P.; Molin, P.; Grajek, W.; Bensoussan, M.: Influence of the water activity of a solid substrate on the growth rate and sporogenesis of filamentous fungi. Biotechnol. Bioeng. 31 (1988) 457–463

Norrish, R.S.: An equation for the activity and equilibrium relative humidities of water in confectionary sirups, J. Food. Technol. 1 (1966) 476–484

Gervais, P.; Sarrette, M.: Influence of age of mycelium and water activity of the medium on aroma production by Trichoderma viride grown on solid substrate. J. Ferment. Bioeng. 69 (1990) 46–50

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Tisseyre, B., Coquille, J.C. & Gervais, P. Conception and characterization of a continuous plug flow bioreactor. Bioprocess Eng. 13, 113–118 (1995). https://doi.org/10.1007/BF00369693

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00369693