Abstract

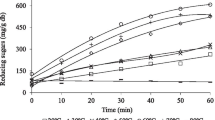

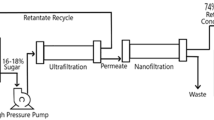

Kinetics of enzymatic hydrolysis of starch to high maltose syrup (by simultaneous use of β-amylase and isoamylase) has been studied here. Main product of dual-enzyme system, maltose, showed a competitive inhibition effect on apparent overall activity of enzymes. Thermal inactivation behavior could be expressed by an empirical exponential function. A mathematical model developed here has described performance of an ultrafiltration reactor (UFR) system by considering effects of product inhibition, enzyme deactivation, and formation of side-product. Effects of concentrations in substrate and enzymes, with residence time of substrate on the performance of UFR has been investigated. Proposed model has been successfully verified in simulating experimental data under various conditions. Operation stability of UFR has also been studied.

Similar content being viewed by others

References

Martensson, K.: Preparation of an immobilized two-enzyme, β-amylase-pullulanase, to an acrylic copolymer for the conversion of starch to maltose. II. Cocoupling of the enzymes and use in a packed bed column. Biotechnol. Bioeng. 17 (1974) 579–591

Reilly, P. J.: Potential and use of immobilized carbohydrases. In: Pitcher, H. W. (Ed.): Immobilized enzymes for food processing, pp. 113–151. Florida: CRC Press, Inc. 1980

Hartmeier, W.: Immobilized biocatalysts-from simple to complex systems. Trends Biotechnol. 3 (1985) 149–153

Ohlson, I.; Tragardh, G.; Hahn-Hagerdal, B.: Enzymatic hydrolysis of sodium hydroxide-pretreated sallow in an ultrafiltration membrane reactor. Biotechnol. Bioeng. 26 (1984) 647–653

Ohshima, T.; Wandrey, C.; Kula, M. R.; Soda, K.: Improvement for L-leucine production in a continuously operated enzyme membrane reactor. Biotechnol. Bioeng. 27 (1985) 1616–1618

Darnoko, D.; Cheryan, M.; Artz, W. E.: Saccharification of cassava starch in an ultrafiltration reactor. Enzyme Microb. Technol. 11 (1989) 154–159

Martensson, K.: Preparation of an immobilized two-enzyme system, β-amylase-pullulanase, to an acrylic copolymer for the conversion of starch to maltose. III. Process kinetic studies on continuous reactors. Biotechnol. Bioeng. 16 (1974) 1567–1587

Shiraishi, F.; Kawakami, K.; Yuasa, A.; Kojima, T.; Kusunoki, K.: Kinetic expression for maltose production from soluble starch by simultaneous use of β-amylase and debranching enzymes. Biotechnol. Bioeng. 30 (1987) 374–380

Houng, J. Y.; Chen, K. C.; Hsu, W. H.: Optimization of cultivation medium composition for isoamylase production. Appl. Microbiol. Biotechnol. 31 (1989) 61–64

Yokobayashi, K.; Misaki, A.; Harada, T.: Purification and properties of Pseudomonas isoamylase. Biochim. Biophys. Acta 212 (1970) 458–469

Houng, J. Y.; Chiou, J. Y.; Chen, K. C.; Hsu, W. H.: Characteristics of starch hydrolysis using β-amylase and isoamylase. J. Chinese Agric. Chem. Soc. 29 (1991) 54–60

Hollo, J. E.; Laszlo, E.; Hoschke, A.: Mechanism of amylolytic starch degradation. Die Stärke 25 (1973) 1–36

Kitagawa, H.; Amemura, A.; Harada, T.: Studies on the inhibition and molecular properties of crystalline Pseudomonas isoamylase. Agric. Biol. Chem. 39 (1975) 989–994

Davis, B. J.: Disc electrophoresis — II. Method and application to human serum proteins. Ann. N.Y. Acad. Sci. 121 (1964) 404

Closset, G. P.; Cobb, J. T.; Shah, Y. T.: Study of performance of a tubular membrane reactor for an enzyme catalyzed reaction. Biotechnol. Bioeng. 16 (1974) 345–360

Madgavkar, A. M.; Shah, Y. T.; Cobb, J. T.: Hydrolysis of starch in a membrane reactor. Biotechnol. Bioeng. 19 (1977) 1719–1726

Hong, G. T.; Tsao, T.; Wankat, P. C.: Membrane reactor for enzymatic hydrolysis of cellobiose. Biotechnol. Bioeng. 23 (1981) 1501–1516

Gianfreda, L.; Livosi, A. M.; Scarfi, M. R.; Greco Jr., G.: β-D-Glucosidase stabilization in a polarized ultrafiltration membrane reactor. Enzyme Microb. Technol. 4 (1982) 322–326

Larsson, M.; Mattiasson, B.: Continuous conversion of starch to ethanol using a combination of an aqueous two-phase system and an ultrafiltration unit. In: Laskin, A. I.; Tsao, G. T.; Wingard Jr., L. B. (Eds.): Enzyme engineering, vol. 7, pp. 144–147. New York: New York Academy of Sciences 1984

Gianfreda, L.; Pirozzi, D.; Greco Jr., G.: Microenvironmental effect of stabilizing polyelectrolytes in ultrafiltration membrane enzymatic reactors. Biotechnol. Bioeng. 33 (1989) 1067–1071

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Houng, J.Y., Chiou, J.Y. & Chen, K.C. Production of high maltose syrup using an ultrafiltration reactor. Bioprocess Eng. 8, 85–90 (1992). https://doi.org/10.1007/BF00369269

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00369269