Abstract

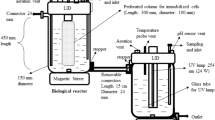

A comparative study between two reactors, one using microorganisms entrapped in calcium alginate gel, and the other using microorganisms attached on the surface of a membrane (polymeric microporous sheeting, MPSTM) to biodegrade phenol is performed. Results indicate that the alginate bead bioreactor is efficient at higher phenol concentrations while the membrane bioreactor shows better performance at lower phenol concentrations. This unique response is primarily attributed to the different techniques by which the microorganisms are immobilized in the two reactors.

In batch mode, below a starting concentration of 100 ppm phenol, biodegradation rates in the membrane bioreactor are (7.58 to 12.02 mg phenol/h · g dry biomass) atleast 10 times the rates in alginate bead bioreactor (0.74 to 1.32 mg phenol/h · g dry biomass). Biodegradation rates for the two reactors match at a starting concentration of 250 ppm phenol. Above 500 ppm phenol, the rates in the alginate bead bioreactor are (7.3 to 8.1 mg phenol/h · g dry biomass) on an average 5.5 times the corresponding rates in the membrane bioreactor (2.18 to 1.03 mg phenol/h · g dry biomass).

In continuous feed mode the steady state degradation rates in the membrane bioreactor are one to two orders of magnitude higher than the alginate bead bioreactor below 150 ppm inlet phenol concentration. At an inlet concentration around 250 ppm phenol the rates are comparable. Above 500 ppm of phenol the rates in the alginate bioreactor are an order of magnitude high than the membrane bioreactor.

Due to substrate inhibition, and its inability to sustain a high biomass concentration, the membrane bioreactor shows poor efficiencies at phenol concentrations above 250 ppm. At low phenol concentrations the apparent reaction rates in the alginate bead bioreactor decrease due to the diffusional resistance of the gel matrix, while biodegradation rates in the membrane bioreactor remain high due to essentially no external diffusional resistance.

Results indicate that a combined reactor system can be more effective for bioremediation than either separate or attached microbial reactors.

Similar content being viewed by others

References

Lallai, A.; Mura, G.: Kinetics of growth for mixed cultures of microorganisms growing on phenol. The Chemical Engineering Journal. 41 (1989) B55-B60

Lakhwala, F. S.; Lodaya, M. P.; Yang, K. C.; Lewandowski, G. A.; Softer, S. S.: Design of toxic waste treatment bioreactor: viability studies of microorganisms entrapped in alginate gel. Proceedings of the International Conference on Physiochemical and Biological Detoxification of Hazardous Wastes, Y. C. Wu (Ed), Vol II pp 587–599, 1988

Mattiasson, B.: Immobilization methods. In: Immobilized Cells and Organelles, vol. I, B. Mattiasson, (Ed.) CRC Press, Boca Raton, Fl. Chap 2, 3–26 (1983)

Sofer, S. S.; Lewandowski, G. A.; Lodaya, M. P.; Lakhwala, F. S.; Yang Kai-Chung, and Singh Manjari: Biodegradation of 2-chlorophenol using immobilized activated sludge, Res. JWPCF, 62 (1990) 73–80

Livingston, A.; Chase, H.: Modeling phenol degradation in a fluidized-bed reactor. AIChE Journal 35 (1989) 1980–1992

Bettmann, H.; Rehm, H. J.: Continuous degradation of phenol(s) by pseudomonas putida P8 entrapped in polyacrylamidehydrazide. Appl. Microbiol. Biotechnol. 22 (1985) 389–393

Fan, L. S.; Leyva-Ramos, R.; Wisecarver, K. D.; Zehner, B. J.: Diffusion of phenol through a biofilm grown on activated carbon particles in a draft-tube three-phase fluidized-bed bioreactor. Biotech. Bioeng. 35 (1990) 279–286

Hammoda, M. F.; Al-Haddad, A. A.: Investigation of petroleum refinery effluent treatment in an aerobic fixed-film biological system. J. Inst. Water Environ. Manage. 1 (1987) 239–246

Sofer, S. Lewandowski, G.; Lodaya, M.; Lakhwala, F.; Rus, E.; Singh, M.: Biodegradation of benzene and a BTX mixture using immobilized activated sludge. To be published in journal of environmental science and health, Oct. 1990

Hausser, A.; Goldberg, B.; Mertens, J.: An immobilized two-enzyme system (fungal a-amylase/glucoamylase) and its use in the continuous production of high conversion maltose-containing corn syrups“. Biotech. Bioeng. 25 (1983) 525–539

Lakhwala, F.; Sinkar, V.; Goldberg, B.; Sofer, S.: A polymeric membrane reactor for biodegradation of phenol in wastewater“. Journal of bioactive and compatible polymers. 5 (1990) 439–452

Loosdrecht, M.; Norde, W.; Zehnder, A.: Influence of cell surface characteristics on bacterial adhesion to solid supports. Proc. 4th European Congress on Biotechnology. 4 (1987) 575–580

Wollersheim, R.: Adhesion and biofilm development of acetate, propionate, and butyrate degrading microorganisms on glass surfaces. Biotech. Lett. 11 749–752

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lakhwala, F.S., Goldberg, B.S. & Sofer, S.S. A comparative study of gel entrapped and membrane attached microbial reactors for biodegrading phenol. Bioprocess Eng. 8, 9–18 (1992). https://doi.org/10.1007/BF00369258

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00369258