Abstract

An approximate analysis using a bilinear representation of the stress-strain behaviour has been made for the energy of plastic deformation at the tip of a crack growing under sinusoidal loading of constant amplitude. The energy of plastic deformation results from hysteretic and non-hysteretic plastic deformation. It is shown that the energy due to hysteresis is independent of the rate of growth of the crack whereas energy due to non-hysteretic plastic deformation is dependent on growth rate. Work hardening due to hysteretic plastic deformation is not considered in the analysis.

The energy balance criterion which is basic to fracture mechanics has been applied to the problem of crack growth under cyclic loading, considering the energy due to hysteretic plastic deformation in the plastic enclave as obtained in the analysis. The equation of energy balance results in an expression for crack growth rate, consistent with the general trends observed in experiments.

Some of the merits and limitations of the energy formulation of fatigue crack growth have been discussed.

Résumé

On a effectué une analyse approchée de l'énergie de déformation plastique à l'extrémité d'une fissure au cours de propagation sous contraintes sinusoïdales d'amplitude constante, en recourant à une represéntation bilinéaire de la fonction tension-déformation. L'énergie de déformation plastique provient de déformations plastiques de caractères hystérétique et non hystérétique.

On démontre que l'énergie associée à l'hystérésis ne dépend pas de la vitesse de propagation de la fissure, tandis que l'énergie associée aux déformations plastiques non hystérétiques en dépend. On ne considère pas dans l'analyse l'écrouissage résultant des déformations plastiques hystérétiques.

Le critère d'équilibre des énergies, fondamental en mécanique de la rupture, a été appliqué au problème de la propagation des fissures sous charges cycliques. L'énergie considérée est celle qui résulte de la déformation plastique hystérétique dans l'enclave plastique à la pointe de la fissure. En exprimant l'équilibre énergétique sous sa forme analytique, on trouve une expression de la propagation des fissures qui satisfait aux tendances générales observées expérimentalement.

On discute enfin les avantages et les limitations d'une formulation de la propagation des fissures de fatigue, basée sur des considérations énergétiques.

Zusammenfassung

Mit Hilfe einer bilinearen Darstellung der Abhängigkeit Spannung-Verformung wird eine angenäherte Analyse der plastischen Verformungsenergie an der Spitze eines sich unter sinusoïdalen Spannungen konstanter Amplitude entstehenden Risses vorgenommen. Diese Energie ergibt sich aus hysteretischen und nicht hysteretischen Verformungen. Es wird gezeigt, daß die sich aus der Hysteresis ergebende Energie nicht von der Fortpflanzungsenergie abhängig ist, im Gegensatz zum Energieanteil der nicht hysteretischen plastischen Verformung, welche von der Riß-wachstumsgeschwindigkeit abhängt. Bei der vorliegenden Analyse wird die Verformungshärtung, die sich aus der hysteretischen plastischen Verformung ergibt, nicht berücksichtigt.

Das Energiegleichsgewichtkriterium, welches für die Bruchmechanik von grundlegender Bedeutung ist, wurde auf den Fall der Rißfortpflanzung unter zyklischer Beanspruchung angewendet, wobei die sich durch die hysteretische plastische Verformung in der plastischen Enklave ergebende Energie aus der oben erwähnten Analyse erhalten wurde. Die Energiebilanzgleichung führt zu einem Ausdruck der Rißfortpflanzungsgeschwindigkeit, welcher mit dem bei den Versuchen beobachteten allgemeinen Verlauf übereinstimmt.

Es werden einige Vorteile und Begrenzungen einer auf Energieüberlegungen begründeten Formulierung der Ermüngsrißfortpflanzung erörtert.

Similar content being viewed by others

Abbreviations

- 2a :

-

Crack length

- t :

-

Thickness of sheet

- τoct :

-

Octahedral shear stress at any point near the crack tip

- \(\widetilde\tau _{{\text{oct}}}\) :

-

Octahedral shear stress range at any point near the crack tip under constant amplitude cyclic loading conditions

- γoct :

-

Octahedral shear strain at any point near the crack tip

- \(\tilde \gamma _{oct} \) :

-

Octahedral shear strain range at any point near the crack tip under constant amplitude cyclic loading condition

- τoct el :

-

Octahedral shear stress at any point near the crack tip given by an elastic analysis

- \(\widetilde\tau _{_{{\text{oct}}} }^{{\text{el}}}\) :

-

Octahedral shear stress range at any point near the crack tip under constant amplitude cyclic loading given by an elastic analysis

- τoli :

-

Octahedral shear stress at yield under monotonic loading (Fig. 2)

- \(\widetilde\tau _{{\text{oli}}}\) :

-

Octahedral shear stress at yield under cyclic loading (Fig. 2)

- γ:

-

\({\text{ = }}\widetilde\tau _{{\text{oli}}} /\tau _{{\text{oli}}}\)

- E :

-

Young's modulus

- E s :

-

Secant modulus

- G :

-

Shear modulus

- G s :

-

Secant modulus of the octahedral shear stress-strain curve

- G t :

-

As defined in Fig. 2

- λ:

-

\(G/G_t ;{\text{ }}\xi = \tau _{{\text{oct}}} /\tau _{{\text{oli ; }}} \xi = \widetilde\tau _{{\text{oct}}} /\widetilde\tau _{{\text{oli ; }}} \alpha = \tau _{_{{\text{oct}}} }^{{\text{el}}} /\tau _{{\text{oli ; }}} \widetilde\alpha = \widetilde\tau _{_{{\text{oct}}} }^{{\text{el}}} /\widetilde\tau _{{\text{oli ; }}}\)

- \(\widetilde\alpha _0\), \(\xi _0\) :

-

Critical values of \(\widetilde\alpha\) and \(\widetilde\xi\) beyond which fracture processes are active

- K max :

-

Stress intensity factor corresponding to maximum stress in the cycle

- K R :

-

Stress intensity factor corresponding to stress range

- W P :

-

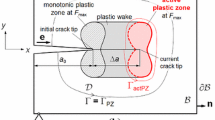

Plastic enclave width corresponding to maximum stress in the cycle and is given by K max/9τoli 2 (Refer Fig. 1)

- \(\tilde w_p \) :

-

Plastic enclave width corresponding to stress range and is given by \(K_{R{\text{ }}}^2 /9\widetilde\tau _{{\text{oli}}}^2\) (Refer Fig. 1)

- U P :

-

Non-hysteretic energy density at any point in the plastic enclave

References

P. C. Paris, The fracture mechanics approach to fatigue, Fatigue—An interdisciplinary approach, proceedings of the 10th Sagamore Army Materials Research Conference, Syracuse University Press (1964) 107–132.

P. C. Paris and F. Erdogan, A. critical analysis of crack propagation laws, Trans. ASME, 85 (1963) 528–534.

S. Pearson, Fatigue crack propagation in metals, Nature, 211 (1966) 1073–1078.

R. G. Forman, V. E. Kearvey and R. M. Engle, Numerical Analysis of crack propagation in cyclically loaded structures, Transactions of ASME, Journal of ASME, Journal of Basic Engineering, 89, 3 (1967) 459–464.

V. Gallina, G. P. Galotto and M. Omini, On a possible model of crack propagation in a solid subjected to a cyclic loading, International Journal of Fracture Mechanics, 3 (1967) 37–44

C. M. Hudson and J. T. Scardina, Effect of stress ratio on fatigue crack growth, Engineering fracture mechanics, 1, 3 (1969) 430–445.

K. N. Rain, On the calculation of plastic energy dissipation rate during stable crack growth, Int. Journal of Fracture Mechanics, 5, 2 (1969) 101–112.

J. R. Dixon, Stress and strain distributions around cracks in sheet materials having various work hardening characteristics, Int. Journal of Fracture Mechanics, 1, 3 (1965) 224–242.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Raju, K.N. An energy balance criterion for crack growth under fatigue loading from considerations of energy of plastic deformation. Int J Fract 8, 1–14 (1972). https://doi.org/10.1007/BF00185193

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00185193