Abstract

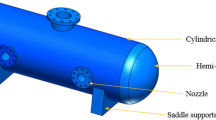

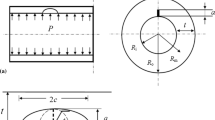

Photoelastic stress analysis has been used to determine stress intensity factors in two types of cracks in the vicinity of radial nozzles in cylindrical pressure vessels. Empirical relationships are presented and validated by tests on 35 models. It is also shown that the values for lateral cracks can be deduced from those predicted for a part-through crack in a plate by applying a curvature correction factor.

Résumé

Une analyse photoélastique de contraintes a été utilisée pour déterminer les facteurs d'intensité de contraintes dans le cas de 2 types de fissures au voisinage d'un piètement radial placé dans un récipient sous pression cylindrique.

Des relations empiriques sont présentées et validées par des essais sur 35 modèles. On montre également que les valeurs relatives à des fissures latérales peuvent être déduites de celles que l'on peut prédire pour une fissure traversante dans une tôle, en appliquant un facteur de correction de courbure.

Similar content being viewed by others

References

ASMEThe Surface Crack-Physical Problems and Computational Solutions (1972).

P. C. Paris and G. Sih, “Stress analysis of cracks”, in ASTM-STP, 381,Fracture Toughness Testing and its Applications (1964).

D.S. Dugdale, Journal of the Mechanics and Physics of Solids, 8 (1960) 100–104.

E. S. Folias, in Y. C. Fung and E. E. Sechler, eds.,Thin-Shell Structures, Prentice-Hall (1974).

B. Aamodt, P. C. Bergan and H. F. Klern, “Calculation of stress intensity factors and fatigue crack propagation of semi-elliptical part-through surface cracks”, Proceedings of 2nd International Conference Pressure Vessel Technology, ASME San Antonio (dy1973).

J. Reynen, ASME paper 75-PVP-20,Journal of Pressure Vessel Technology (1975).

T. K. Hellen and A. R. Dowling, “Three-dimensional crack analysis applied to an LWR nozzle-cylinder intersection”, Central Electricity Generating Board report RD/B/N3042 (July, 1974).

A. S. Kobayashi,The Experimental Determination of Stress Intensity Factors,1 S.E.S.A. (1973).

G. Pearson and C. Ruiz, “Centrifugal casting applied to model vessels”, Strain, 12 (1976) 20–21.

C. Ruiz, “Stress intensity factors for nozzle corner cracks”, Strain 9 (1973) 7–9.

M. A. Schroeld, C. W. Smith and J. J. McGowan, “Determination of Stress intensity factors from photo-elastic data with applications to surface flow problems”, report Virginia Polytechnic Institute-E-73-1 (1973).

R.M. Marloff, M.M. Levan, R.L. Johnson and T.N. Ringler, Experimental Mechanics, 11 (1975) 529–539.

C. Ruiz, “Experimental determination of the stress distribution around notches and slits in cylindrical pressure vessel configurations”, Proceedings of 4th Conference on Experimental Stress Analysis, J. Mech. E. London (1970).

W.F. Brown and J.E. Srawley, “Fracture toughness testing”, Fracture Toughness Testing and its Applications, ASTM STP 381 (1965) 188–193.

O.L. Bowie and D.M. Neal, International Journal of Fracture Mechanics, 13 (1967) 111–119.

V. Weiss and S. Yukawa, “Critical appraisal of Fracture Mechanics”, Fracture Toughness Testing and its Applications, ASTM STP 381 (1964).

C.W. Smith and M.A. Schroedl, Engineering Fracture Mechanics, 7 (1975) 341–345.

“Tentative method of test for plane-strain fracture toughness of metallic materials”, ASTM E399-70T (1970).

J.R. Rice, N. Levy, “The part through crack in an elastic plate”, Journal of Applied Mechanics, 39, ASME series E (1972) 185–194.

British Standards, “Draft rules for the derivation of acceptance levels for defects in fusion welded joints”, WEE/37 (1975).

Author information

Authors and Affiliations

Additional information

Marconi-Elliott Avionics Ltd.

Rights and permissions

About this article

Cite this article

Pearson, G., Ruiz, C. Stress intensity factors for cracks in pressure vessel nozzles. Int J Fract 13, 319–339 (1977). https://doi.org/10.1007/BF00040147

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00040147